Double metaporous silicon dioxide material and its preparing method

A silica and double mesoporous technology, applied in the field of double mesoporous silica material and its preparation, can solve the problems of pore structure collapse and environmental pollution, and achieve the effect of concentrated pore distribution and wide pH value range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

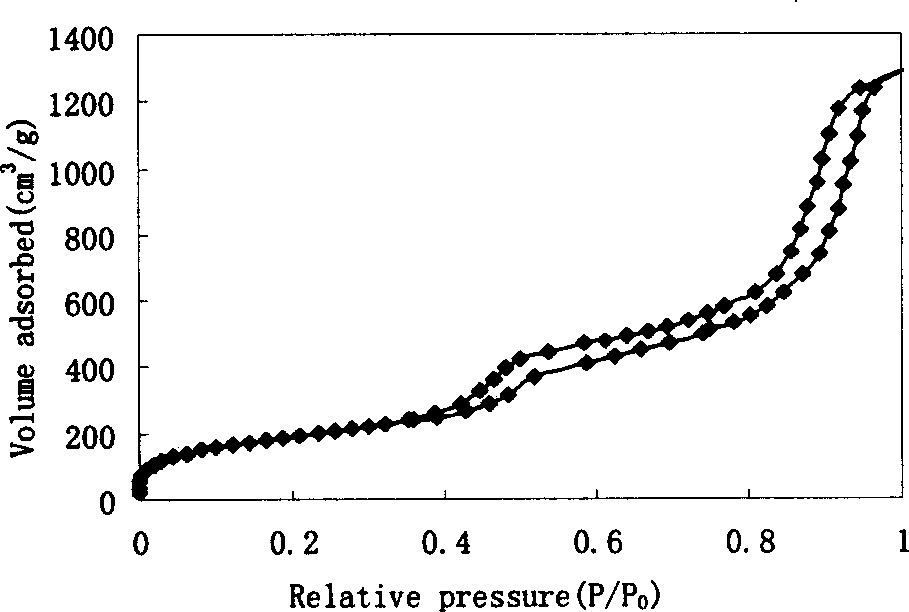

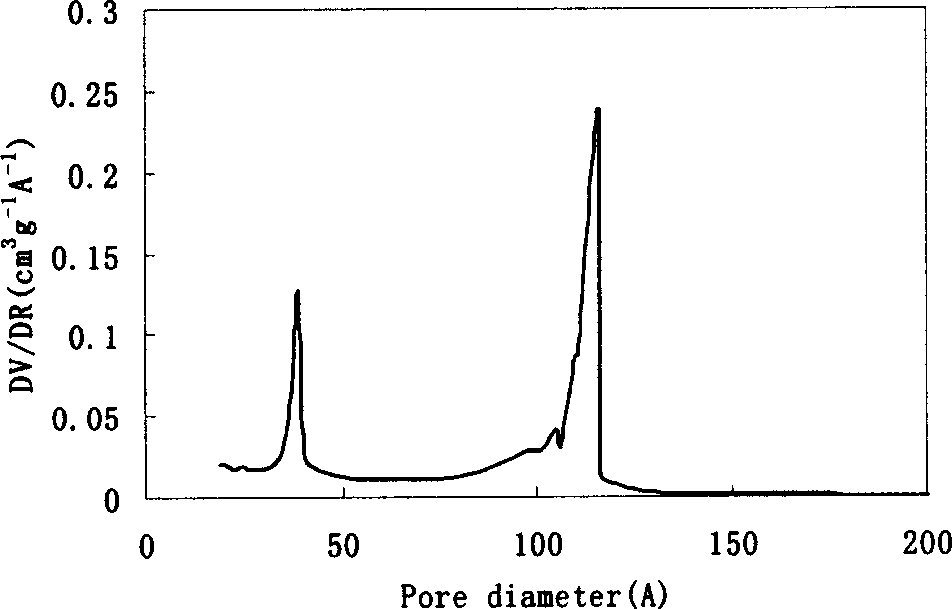

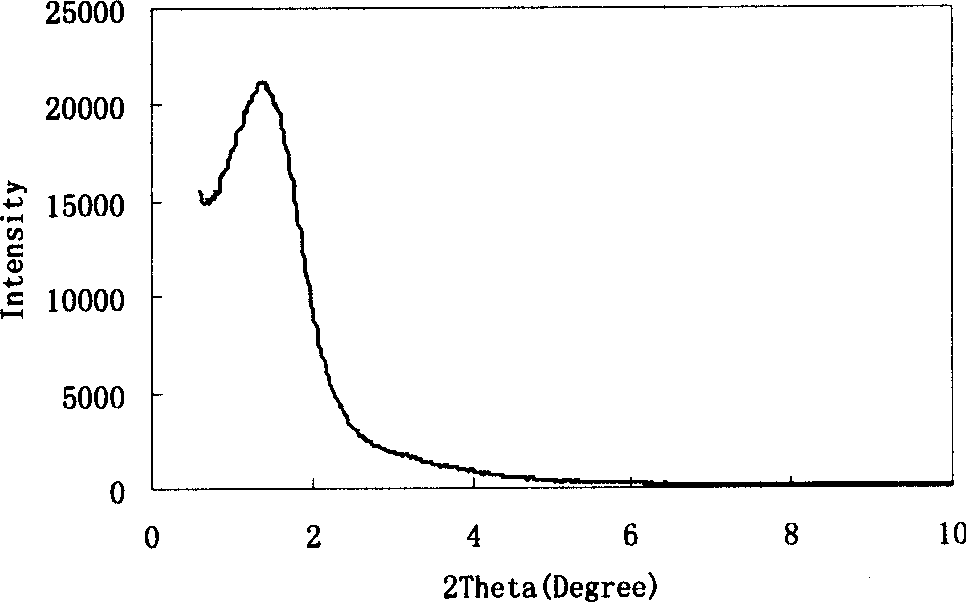

[0019] Mix 0.878g DDAC with 41g distilled water, ultrasonicate at 50°C for 2 hours to obtain a uniform and transparent surfactant solution, adjust the pH of the solution to 12.0 with NaOH, slowly add 2.0833g TEOS dropwise under stirring, stir at room temperature for 24 hours, and seal at 70°C Aged for 4 days, filtered, washed with distilled water, and dried to obtain a synthetic raw powder. The raw powder was refluxed in methanol / hydrochloric acid solution for 48 hours, washed with methanol, and dried to obtain a double mesoporous silica material. The characterization results are shown in the attached figure: figure 1 , figure 2 , image 3 (Other examples are similar to this), the small pore diameter of the material is 3.9nm, the large pore diameter is 11.6nm; the specific surface area is 718.2cm 2 / g; pore volume 1.46cm 3 / g.

Embodiment 2

[0021] Mix 0.3156g of DDAC with 41g of distilled water, ultrasonicate at 50°C for 2 hours to obtain a uniform and transparent surfactant solution, adjust the pH of the solution to 7.1, slowly add 2.0833g of TEOS dropwise under stirring, stir at room temperature for 24 hours, then seal and age at 80°C After 4 days, filter, wash with distilled water, and dry to obtain a synthetic raw powder, reflux the raw powder in methanol / hydrochloric acid solution for 48 hours, wash with methanol, and dry to obtain a double mesoporous silica material. The small pore diameter of the material is 3.6nm, the large pore diameter is 17.0nm; the specific surface area is 556.3cm 2 / g; pore volume 1.20cm 3 / g.

Embodiment 3

[0023] Mix 0.3156g DDAC with 41g distilled water, ultrasonicate at 50°C for 2 hours to obtain a uniform and transparent surfactant solution, adjust the pH of the solution to 10.9 with NaOH, slowly add 2.0833g TEOS dropwise under stirring, stir at room temperature for 24 hours, and seal at 70°C Aged for 4 days, filtered, washed with distilled water, and dried to obtain a synthetic raw powder. The raw powder was refluxed in methanol / hydrochloric acid solution for 48 hours, washed with methanol, and dried to obtain a double mesoporous silica material. The small pore diameter of the material is 3.2nm, the large pore diameter is 15.9nm; the specific surface area is 408.6cm 2 / g; pore volume 0.83cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com