Plant reduction preparation method of load-type silver catalyst

A supported silver and catalyst technology, which is applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of the reduction preparation process of silver single substance particles with less active components, and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

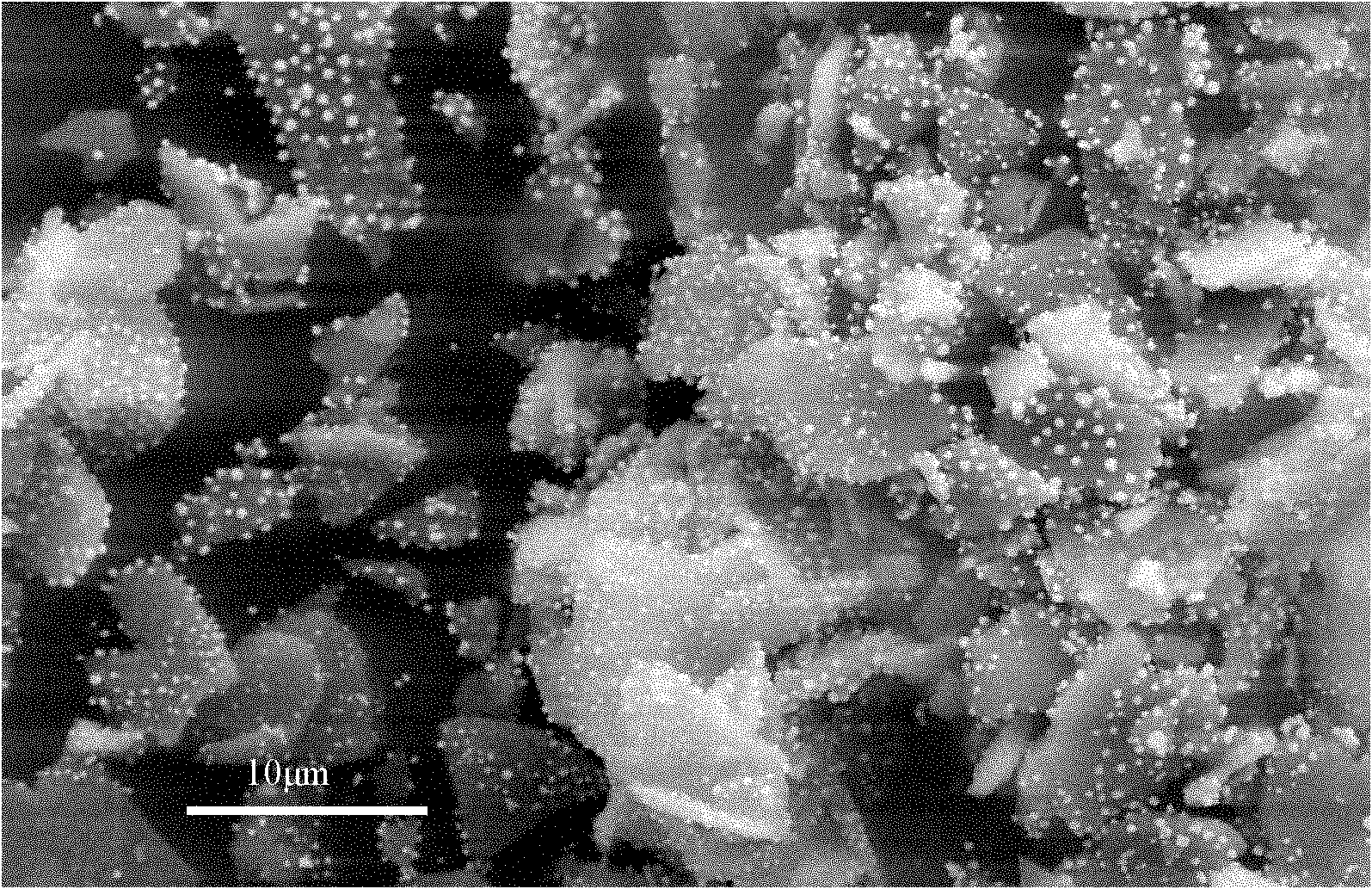

Image

Examples

Embodiment 1

[0021] The leaves of Cinnamomum camphora were dried and pulverized in a blast oven at 60°C. Weigh 1.25g of Cinnamomum camphora leaf powder, disperse in 5mL of deionized water (that is, the leaf / water ratio is 0.25g / mL), shake and extract at room temperature for 6h, centrifuge at 12000rpm for 3min, and remove the centrifuged lower leaf powder residue , leave the supernatant (both cinnamon camphor leaf extract) for subsequent use. Weigh 0.278g of silver nitrate, dissolve it in 1.25mL of cinnamomum camphora leaf extract, add 1g of 20-40 mesh α-alumina, and react at room temperature for 24h. The catalyst precursor was then placed in a vacuum oven at 50 °C for 15 h, and dried under N 2 The catalyst was activated at 600° C. for 60 min in the atmosphere to prepare a catalyst with a silver loading of 15 wt % (calculated based on the total mass of the catalyst).

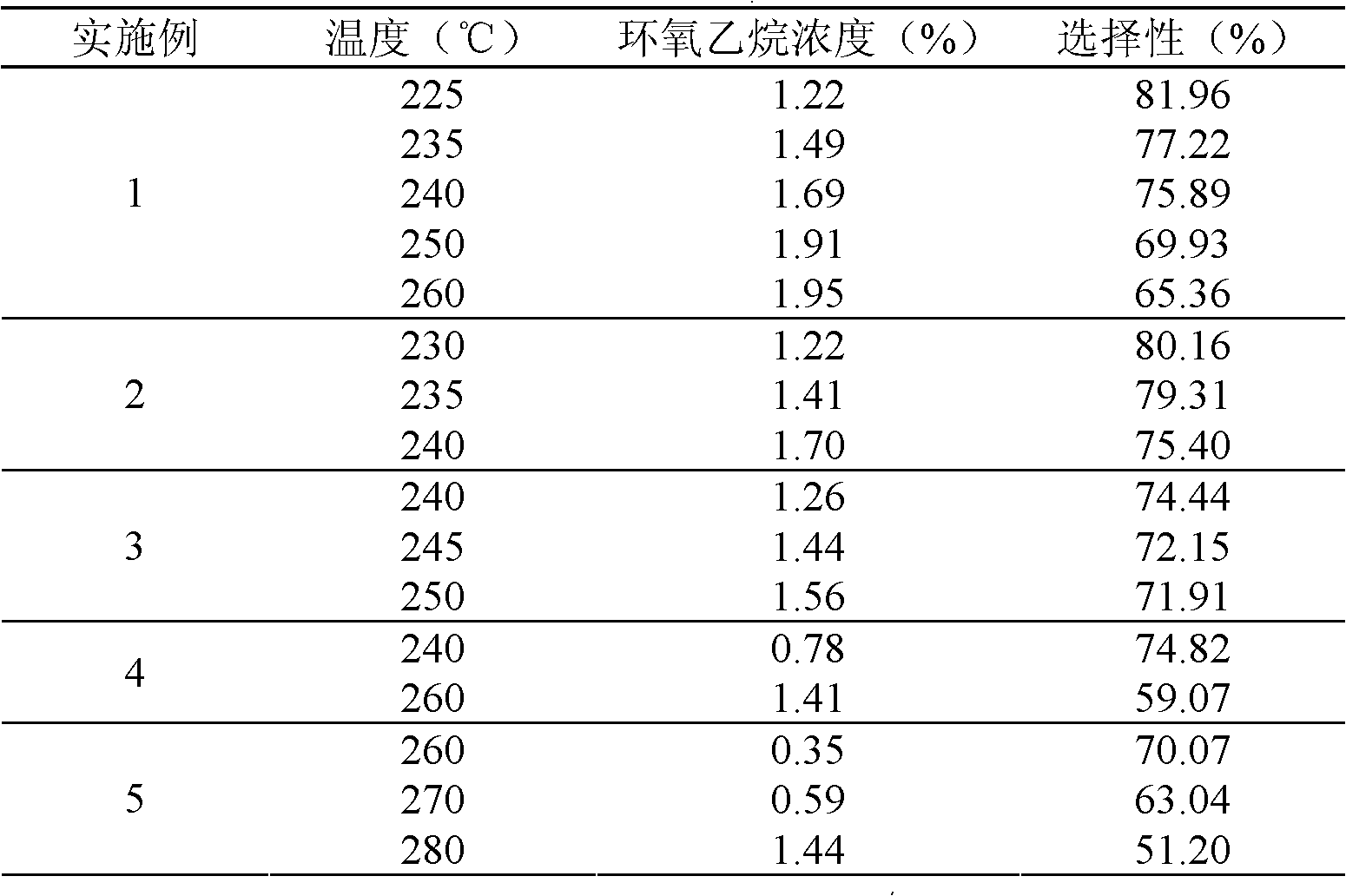

[0022] Catalyst ethylene epoxidation reaction performance test: Take 1mL catalyst and put it into a stainless steel react...

Embodiment 2

[0025] The cinnamon leaves are dried in the sun and crushed. Weigh 1g of Cinnamomum camphora leaf powder, disperse it in 5mL of deionized water (that is, the leaf / water ratio is 0.20g / mL), shake and leach for 5h at room temperature, centrifuge at 12000rpm for 3min, and remove the centrifuged lower leaf powder residue. Leave the supernatant (that is, the extract of cinnamon camphor leaves) for future use. Weigh 0.278g of silver nitrate, dissolve it in 1.25mL of cinnamomum camphora leaf extract, add 1g of 20-40 mesh α-alumina, and react at room temperature for 18h. Afterwards, the catalyst precursor was dried in a vacuum oven at 50 °C for 20 h, and dried under N 2 Activated at 600° C. for 60 min in the atmosphere to prepare a catalyst with a silver loading of 15 wt %.

[0026] The ethylene epoxidation reaction performance test procedure of the catalyst is the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0028] The leaves of Cinnamomum camphora were dried and pulverized in a blast oven at 60°C. Weigh 0.50g of Cinnamomum camphora leaf powder, disperse in 5mL of deionized water (that is, the leaf / water ratio is 0.10g / mL), shake and leach at room temperature for 10h, remove the leaf powder residue by suction filtration and obtain Cinnamomum camphora leaf extract spare. Weigh 0.278g of silver nitrate, dissolve it in 1.25mL of cinnamomum camphora leaf extract, add 1g of 20-40 mesh α-alumina, and react at room temperature for 18h. Afterwards, the catalyst precursor was dried in a vacuum oven at 50 °C for 20 h, and dried under N 2 Activated at 600° C. for 30 minutes in the atmosphere to prepare a catalyst with a silver loading of 15 wt %.

[0029] The ethylene epoxidation reaction performance test procedure of the catalyst is the same as in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com