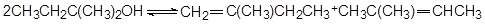

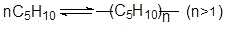

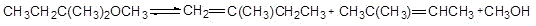

Catalyst for preparing isopentene by cracking methyl tert-amyl ether, preparation method and application

A technology for methyl tertiary amyl ether and isopentene, which is applied to the catalyst and preparation and application fields of methyl tertiary amyl ether cracking to prepare isopentene, and can solve the loss of isopentene, increase in side reactions, product loss, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 30 g γ-Al 2 o 3 Add it to 50ml of 20% phosphotungstic acid solution and let stand at room temperature for 4h, then filter, dry at 100°C for 2h, and roast at 300°C for 6h to obtain POMs / Al 2 o 3 .

[0035] The product was then dissolved in 40ml of 18% La(NO 3 ) 3In aqueous solution, soak for 6 hours, filter, dry at 100°C for 8 hours, and roast at 500°C for 8 hours to obtain La 2 o 3 / POMs / Al 2 o 3 .

[0036] La 2 o 3 / POMs / Al 2 o 3 Add it to 50ml of 20% ammonium fluoride solution, filter, dry at 100°C for 2h, and roast at 500°C for 5h to obtain F / La of the present invention 2 o 3 / POMs / Al 2 o 3 .

[0037] Put 14g of catalyst into a Φ20mm diameter miniature fixed-bed reactor, feed methyl tert-amyl ether with a liquid micro-sampling pump, and control the liquid space velocity to 2.5h -1 , the reaction temperature is 155°C, the conversion rate of TAME is 99.2%, the selectivity of isoamylene is 99.8%, and the selectivity of methanol is 99.8%. The proportio...

Embodiment 2

[0039] 30 g γ-Al 2 o 3 Add it to 50ml of 15% phosphotungstic acid solution and let stand at room temperature for 4h, then filter, dry at 100°C for 2h, and roast at 300°C for 6h to obtain POMs / Al 2 o 3 .

[0040] The product was then dissolved in 40ml of 1% Ce(NO 3 ) 3 In aqueous solution, immersed for 2h, filtered, dried at 150°C for 1h, calcined at 500°C for 4h to obtain Ce 2 o 3 / POMs / Al 2 o 3 .

[0041] Then Ce 2 o 3 / POMs / Al 2 o 3 Add it to 25ml of 10% sodium fluoride solution, filter, dry at 120°C for 5h, and roast at 500°C for 5h to obtain the F / Ce 2 o 3 / POMs / Al 2 o 3 .

[0042] Put 14g of catalyst into a Φ20mm diameter miniature fixed-bed reactor, feed methyl tert-amyl ether with a liquid micro-sampling pump, and control the liquid space velocity to 2.5h -1 , the reaction temperature is 155°C, the conversion rate of TAME is 98.5%, the selectivity of isoamylene is 99.8%, and the selectivity of methanol is 99.5%. The proportion of 2-methyl-1-butene to ...

Embodiment 3

[0044] 30 g γ-Al 2 o 3 Add it to 50ml of 30% phosphomolybdic acid solution and let stand at room temperature for 6h, then filter, dry at 100°C for 2h, and roast at 300°C for 8h to obtain POMs / Al 2 o 3 .

[0045] The product was then dissolved in 40ml of 10% Sm(NO 3 ) 3 Soak in aqueous solution for 6h, filter, dry at 100°C for 4h, and roast at 600°C for 1h to obtain Sm 2 o 3 / POMs / Al 2 o 3 .

[0046] Sm again 2 o 3 / POMs / Al 2 o 3 Add it to 100ml of hydrofluoric acid solution with a concentration of 3%, soak for 1h, filter, dry at 100°C for 4h, and roast at 600°C for 5h to obtain the F / Sm of the present invention 2 o 3 / POMs / Al 2 o 3 .

[0047] Put 14g of catalyst into a Φ20mm diameter miniature fixed-bed reactor, feed methyl tert-amyl ether with a liquid micro-sampling pump, and control the liquid space velocity to 2.5h -1 , the reaction temperature is 155°C, the conversion rate of TAME is 99.5%, the selectivity of isoamylene is 99.8%, and the selectivity of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com