Supplementing refining catalyst for preparing 1,4-butanediol, preparation method and application thereof

A supplementary refining and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of difficult separation of colored impurities, 1,4-butanediol The problem of low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

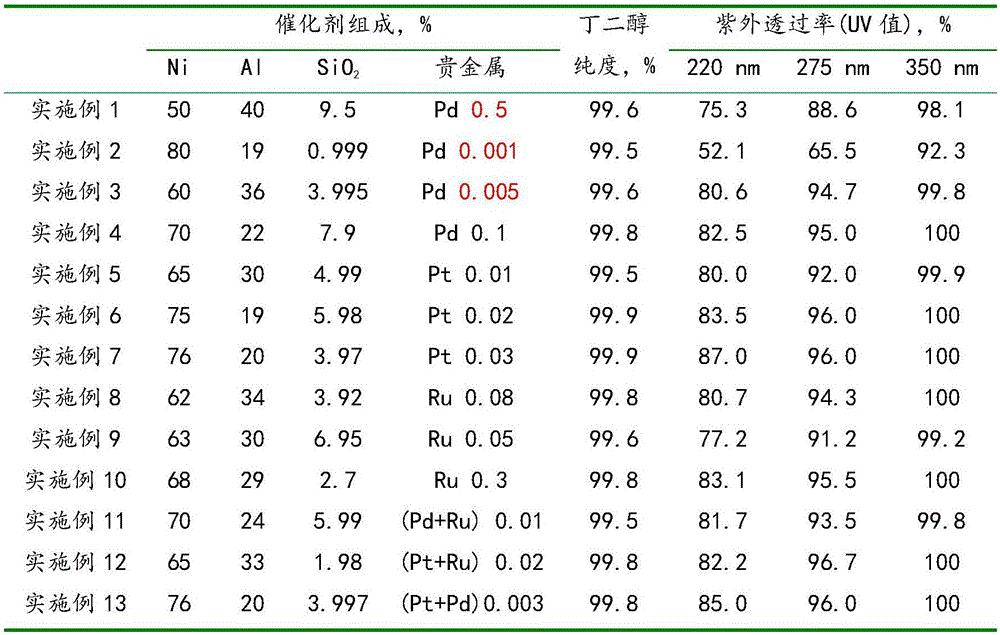

Examples

preparation example Construction

[0020] The preparation method of described supplementary refining catalyst comprises the following steps:

[0021] (1) Mix Ni-Al alloy powder with a particle diameter ranging from 10 to 200 μm, binder hydroxypropyl methylcellulose, and silicon source to obtain material I;

[0022] (2) Add deionized water to material I, knead and extrude into strips with a diameter of 2mm, dry and roast to obtain material II;

[0023] (3) Activate the material II with a NaOH solution with a concentration of 1-25%, the activation temperature is 50-100° C., and wash until neutral after activation for 2 hours to obtain the material III;

[0024] (4) The material III is soaked in an aqueous solution containing a noble metal precursor, soaked for 1 hour, and then washed until neutral to obtain the catalyst of the present invention.

[0025] In the preparation method of the supplementary refining catalyst, the silicon source in step (1) is any one of nano silicon dioxide, silica sol, tetraethyl orth...

Embodiment 1

[0035] Catalyst preparation:

[0036] (1) Mix Ni-Al alloy powder with a particle diameter ranging from 10 to 200 μm, binder hydroxypropyl methylcellulose, and nano-silicon dioxide to obtain material I;

[0037] (2) Add deionized water to material I, knead and extrude into strips with a diameter of 2 mm, dry at 100°C for 10 hours, and roast at 700°C for 2 hours to obtain material II;

[0038] (3) Activate the material II with a 1% NaOH solution at an activation temperature of 50° C., activate for 2 hours and then wash until neutral to obtain the material III;

[0039] (4) Immerse the material III in an aqueous solution containing palladium chloride for 1 hour and then wash until neutral to obtain the catalyst of this embodiment.

[0040] Catalyst evaluation:

[0041] The purity of the 1,4-butanediol raw material used in the catalyst evaluation process was 99.0%, and its ultraviolet transmittance (UV value) at 220nm, 275nm, and 350nm were 0.1%, 0.3%, and 34.0%, respectively. ...

Embodiment 2

[0044] Catalyst preparation:

[0045] (1) Mix Ni-Al alloy powder with a particle diameter ranging from 10 to 200 μm, binder hydroxypropyl methylcellulose, and silica sol to obtain material I;

[0046] (2) Add deionized water to material I, knead and extrude into strips with a diameter of 2 mm, dry at 100°C for 10 hours, and roast at 900°C for 2 hours to obtain material II;

[0047] (3) Activate the material II with a NaOH solution with a concentration of 25%, at an activation temperature of 100° C., and wash to neutrality after activation for 2 hours to obtain the material III;

[0048] (4) The material III was soaked in an aqueous solution containing palladium nitrate for 1 hour, and then washed until neutral to obtain the catalyst of this embodiment.

[0049] Catalyst evaluation:

[0050] The purity of the 1,4-butanediol raw material used in the catalyst evaluation process was 99.0%, and its ultraviolet transmittance (UV value) at 220nm, 275nm, and 350nm were 0.1%, 0.3%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com