Hydrocracking method for producing chemical materials

A technology for hydrocracking and chemical raw materials, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

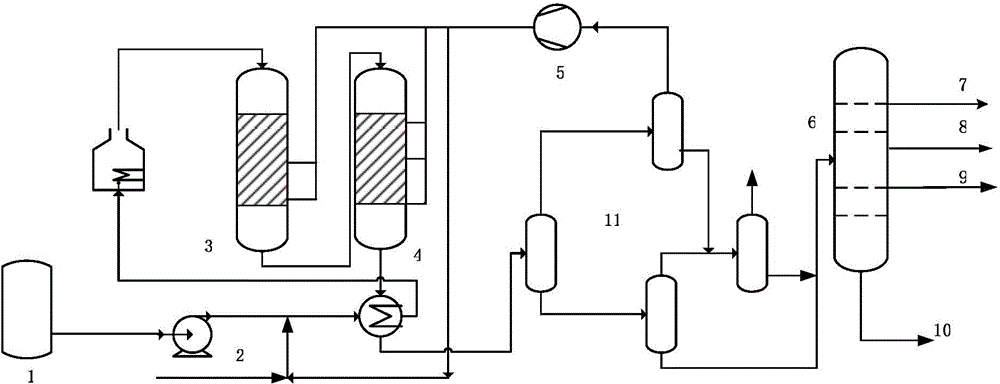

Method used

Image

Examples

Embodiment 1

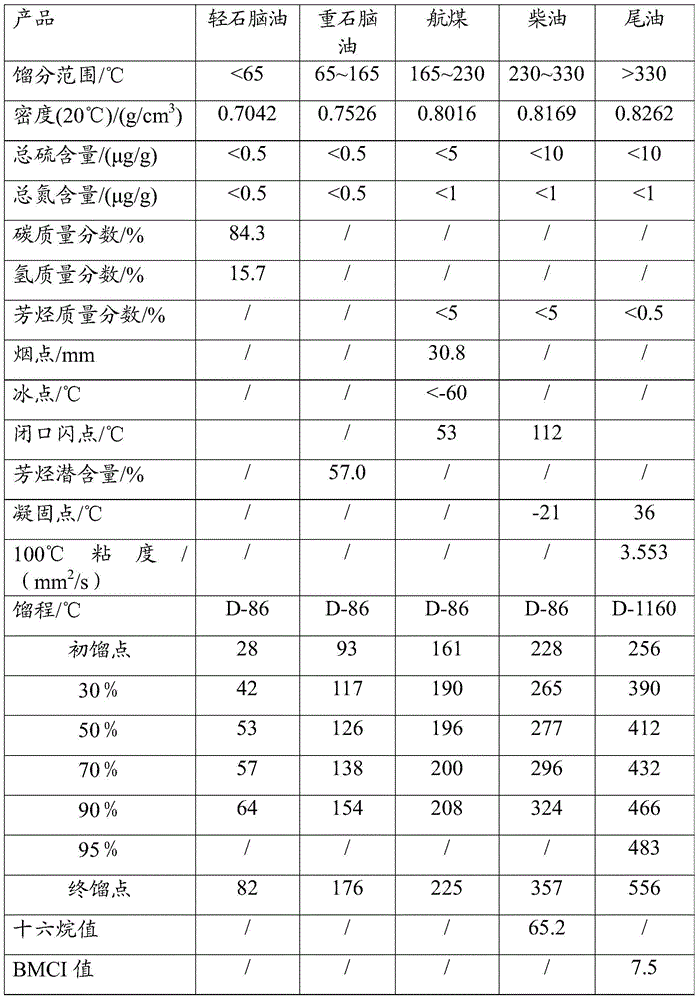

[0085] The test feedstock oil C is a mixture of VGO feedstock A and CGO feedstock B, in which the proportion of CGO incorporated is 40%. The main properties of the VGO feedstock A, CGO feedstock B and feedstock oil C are shown in Table 1.

[0086] In the reaction hydrogen partial pressure 15.0MPa, the refining section is 368 °C, and the volumetric space velocity in the refining section is 1.0h -1 , the cracking section is 375°C, and the volumetric space velocity of the cracking section is 1.5h -1, under the reaction conditions of the hydrogen oil volume ratio of 1200, the main process conditions, the nitrogen content of the refined oil and the product distribution results are shown in Table 2, and the main product properties are shown in Table 3.

[0087] It can be seen from Table 1 that the hydrocracking raw material C is a mixture of VGO and 40% CGO, in which the nitrogen mass fraction reaches 0.23%, which is a relatively inferior wax oil fraction.

[0088] It can be seen f...

Embodiment 2

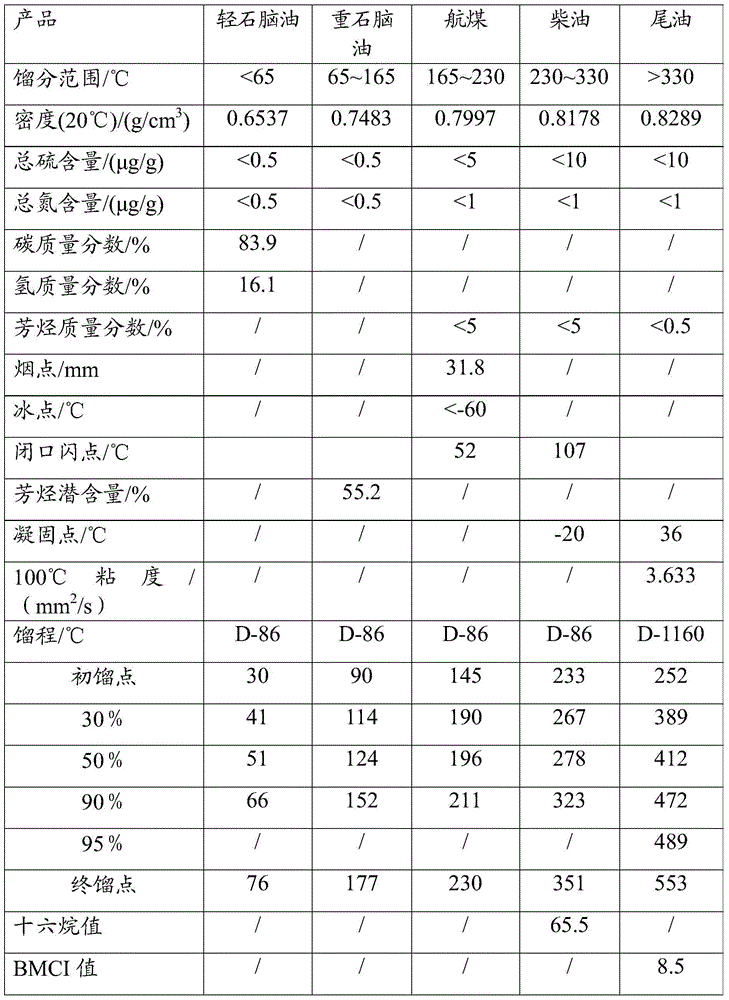

[0097] The test feedstock oil B is 100% CGO, and the main properties of the feedstock oil B are shown in Table 1.

[0098] In the reaction hydrogen partial pressure 15.0MPa, the refining section is 378 °C, and the volumetric space velocity in the refining section is 1.0h -1 , the cracking section is 385°C, and the volumetric space velocity of the cracking section is 1.5h -1 , under the reaction conditions with a hydrogen oil volume ratio of 1200, the main process conditions, the nitrogen content of the refined oil and the product distribution results are shown in Table 4, and the main product properties are shown in Table 5.

[0099] It can be seen from Table 1 that the hydrocracking raw material B is 100% CGO, in which the nitrogen mass fraction reaches 0.37%, which is an inferior hydrocracking feed.

[0100] It can be seen from Table 4 that the air velocity in the refining section is 1.0h -1 , the space velocity of the cracking section is 1.5h -1 Under the same conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com