Method for purifying 1,4-butanediol

A purification method and technology of butanediol, applied in 1 field, can solve the problems of complex reactor structure, increase the difficulty of factories, etc., and achieve the effects of low cost, simple composition and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

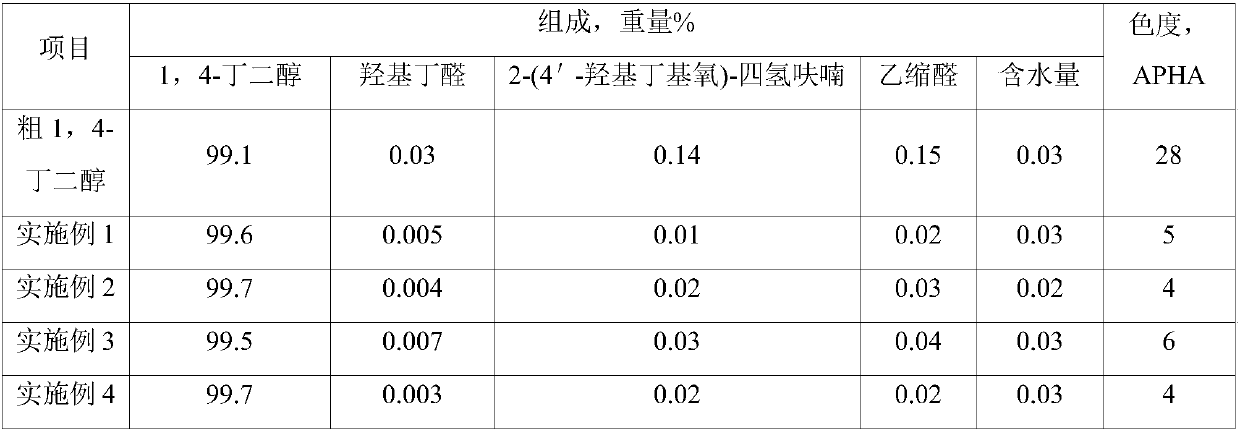

Examples

Embodiment 1

[0040] Take by weighing 100 grams of amino acid phosphoric acid chelating resin LSC-500 and vacuum dry at 80° C. for 2 hours. Preparation 100 milliliters concentration is the silver nitrate aqueous solution of 78.7 grams per liter, under the condition of stirring, add the LSC-500 chelate resin after 100 grams of drying at normal temperature, at 60 ℃ and under stirring aging 8 hours. Pass hydrogen into the mixture after aging to carry out reduction and activation for 4 hours, separate the mixture through reduction and activation to obtain a solid, and the gained solid is washed with water successively and vacuum-dried at 80°C for 2 hours to obtain a silver content of 5% by weight. Silver supported resin catalyst.

[0041] In the fixed-bed reactor, pack 10 grams of the silver-loaded resin catalyst prepared by the present embodiment, and at a temperature of 80° C., a pressure of 2.0 MPa, and a liquid hourly volume space velocity of 2 for crude 1,4-butanediol. Hour -1 , hydrogen...

Embodiment 2

[0043] Weigh 100 grams of iminodiacetoxy-based chelating resin D851 and dry it in vacuum at 80° C. for 2 hours. Preparation 100 milliliters of concentration is the silver nitrate aqueous solution of 78.7 grams per liter, under the condition of stirring, add 100 grams of D851 chelating resins at normal temperature, at 60 ℃ and aging 8 hours under stirring. Pass hydrogen into the mixture after aging to carry out reduction and activation for 4 hours, separate the mixture through reduction and activation to obtain a solid, and the gained solid is washed with water successively and vacuum-dried at 80°C for 2 hours to obtain a silver content of 5% by weight. Silver supported resin catalyst.

[0044] In the fixed-bed reactor, pack 10 grams of the silver-loaded resin catalyst prepared in this embodiment, and at a temperature of 80° C., a pressure of 1.0 MPa, and a liquid hourly volume space velocity of 1,4-butanediol of 2 Hour -1 1, hydrogen and crude 1,4-butanediol are treated unde...

Embodiment 3

[0046] Weighing brand is 100 grams of polystyrene-based chelating resin S-930 and dried in vacuum at 80° C. for 2 hours. Prepare 100 milliliters of concentration and be the silver nitrate aqueous solution of 15.7 grams / liter, under the condition of stirring, add 100 grams of S-930 chelate resins at normal temperature, at 60 ℃ and under stirring aging 8 hours. Pass hydrogen into the aged mixture to carry out reduction activation for 4 hours, separate the mixture through reduction activation to obtain a solid, wash the gained solid with water and vacuum dry at 80° C. for 2 hours to obtain a silver content of 1% by weight. Silver supported resin catalyst.

[0047] In the fixed-bed reactor, pack 10 grams of silver-loaded resin catalysts prepared in this embodiment, and at a temperature of 30° C., a pressure of 3.0 MPa, and a liquid hourly volume space velocity of 1,4-butanediol Hour -1 1, hydrogen and crude 1,4-butanediol are treated under the condition of 10:1 mol ratio to puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com