Efficient hydrogenation process and system for producing hydrogen peroxide through anthraquinone method

A hydrogen peroxide, anthraquinone method technology, applied in the direction of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, chemical instruments and methods, etc., can solve the problem of low diffusion mass transfer rate, The problems of low catalyst space velocity and low hydrogenation reaction rate can achieve the effect of reducing diffusion and mass transfer resistance, high catalyst utilization rate, and improving reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

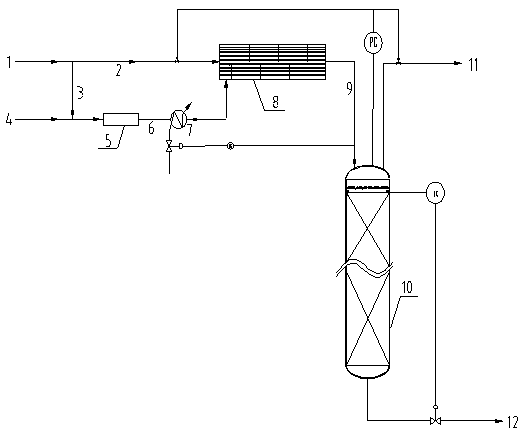

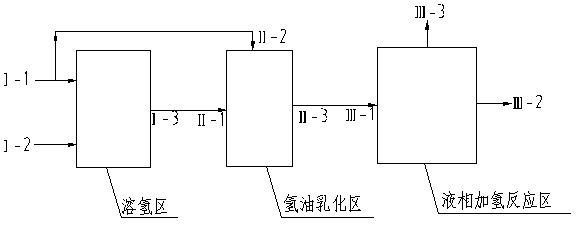

Embodiment 1

[0041] The hydrogenation reaction process and the liquid phase hydrogenation reaction system of the present invention are used to carry out the anthraquinone hydrogenation process. Hydrogenation reactor filling catalyst 0.072m 3 , first hydrogen 13.66Nm 3 / h is divided into two routes of hydrogen I and hydrogen II, and the hydrogen I is 0.07Nm 3 / h, using SMK static mixer structure, the material residence time is 2.5 minutes; hydrogen Ⅱ is 13.59Nm 3 / h, using a shell-and-tube inorganic membrane tube bundle with a pore size of 5nm; 3 / h and hydrogen I0.07Nm 3 / h is introduced into a static mixer and dissolved under a pressure of 5.0MPa to form a working fluid material containing saturated dissolved hydrogen; the working fluid containing saturated dissolved hydrogen is mixed with hydrogen II 13.59Nm 3 / h is introduced into the hydrogen-oil mixer, and the hydrogen-dissolving working fluid is introduced into the shell side of the membrane tube bundle; hydrogen gas II is introd...

Embodiment 2

[0044] The hydrogenation reaction process and the liquid phase hydrogenation reaction system of the present invention are used to carry out anthraquinone hydrogenation process one. Hydrogenation reactor filling catalyst 0.093m 3 , first hydrogen 13.66Nm 3 / h is divided into two routes of hydrogen I and hydrogen II, and the hydrogen I is 0.42Nm 3 / h, using a static mixer structure with spiral plates, the material residence time is 3.5 minutes; the hydrogen gas II is 13.24Nm3 / h, using a shell-and-tube inorganic membrane tube bundle with a pore size of 5nm; 3 / h and hydrogen I0.42Nm 3 / h is introduced into a static mixer and dissolved under a pressure of 9.9MPa to form a hydrogen-dissolving working fluid; the hydrogen-dissolving working fluid is mixed with hydrogen II 13.24Nm 3 / h is introduced into the hydrogen-oil mixer, and the hydrogen-dissolving working fluid is introduced into the shell side of the membrane tube bundle; hydrogen II is introduced into the tube side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com