Hydrofinishing method for crude benzol

A technology for hydrofining and crude benzene, which is applied in the fields of refined hydrocarbon oil, chemical instruments and methods, and hydrocarbons, and can solve problems such as high investment and operating costs, easy blockage, and large loss of aromatic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

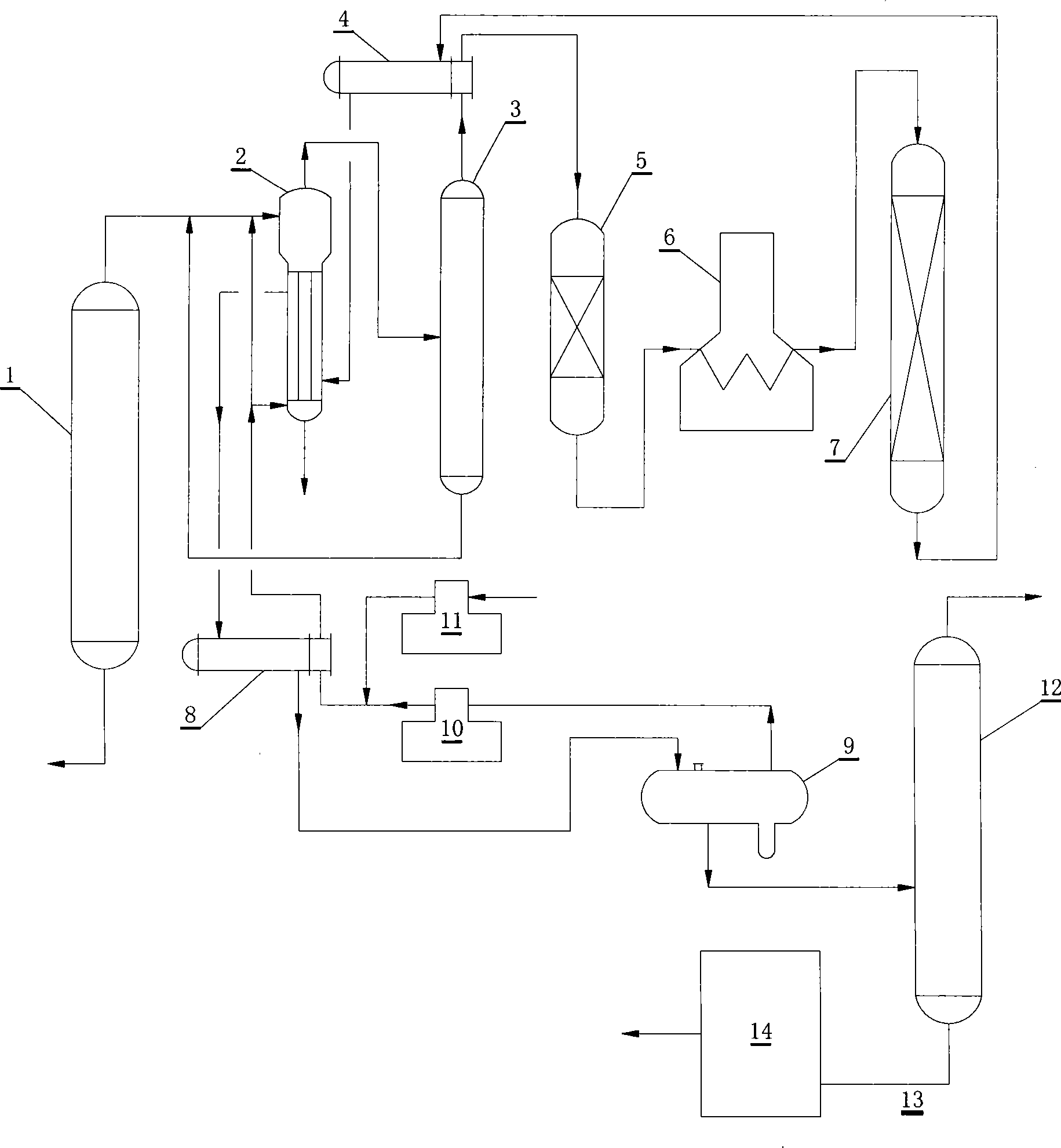

[0022] Such as figure 1 Shown is the schematic flow sheet that a preferred embodiment of the present invention proposes, and coking crude benzene raw material first enters decompression heavy-lifting tower 1, and in the raw material greater than C 9 The heavy components are removed by the decompression system, and the obtained light components are mixed with hydrogen 19 and then enter the multi-stage evaporation system 2; Adjust the heat exchange network in the system to control the cold washing temperature of the evaporation tower; the material flowing out from the lower part of the evaporation tower 3 will return, and the material flowing out from the upper part of the evaporation tower 3 will enter the pre-reactor 5 after taking heat; the pre-reactor 5 The product generated by the reaction is heated by the heating furnace 6 and then enters the main reactor 7; the product generated by the reaction of the material in the main reactor 7 passes through the hydrogenation product...

Embodiment 2-3

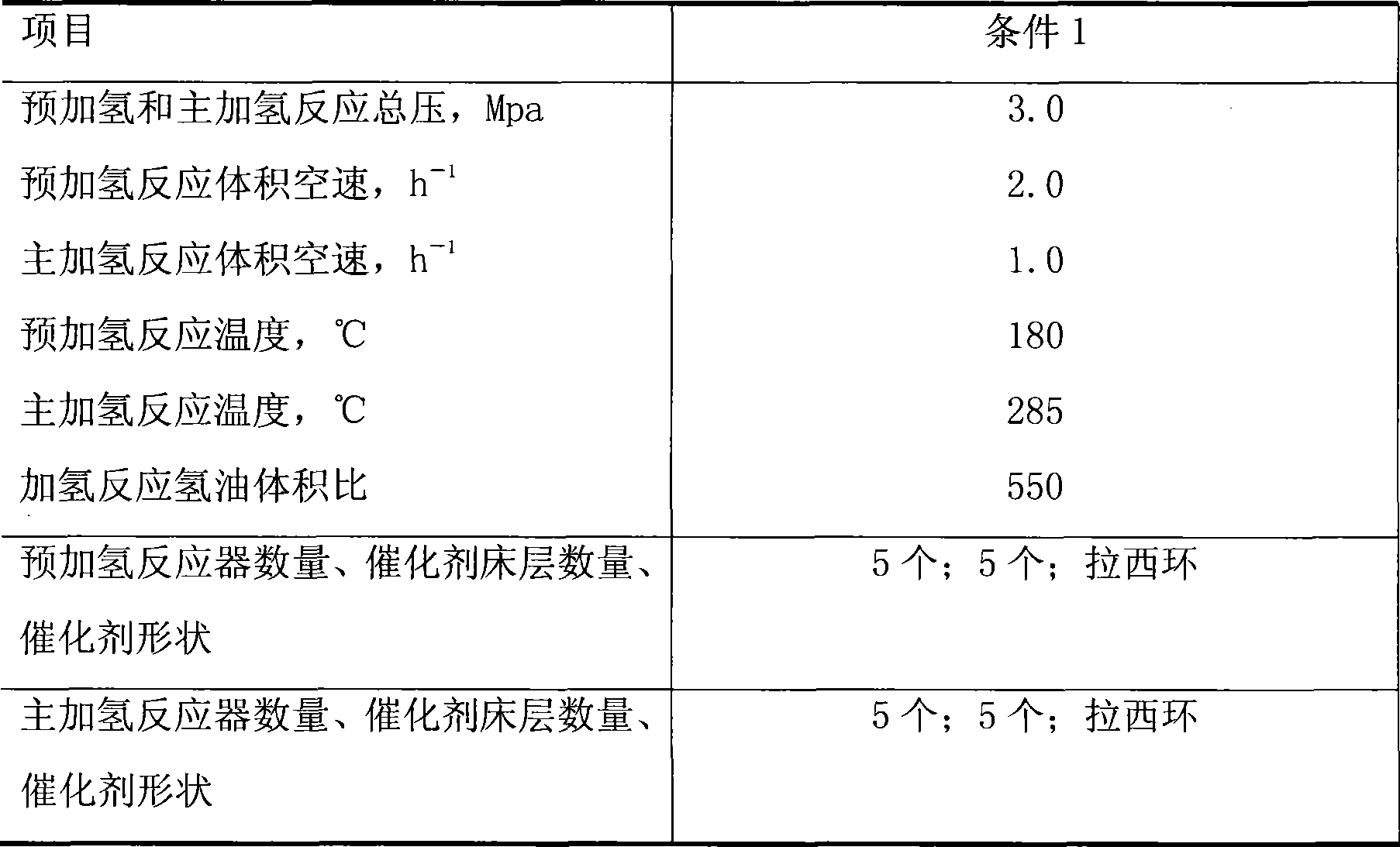

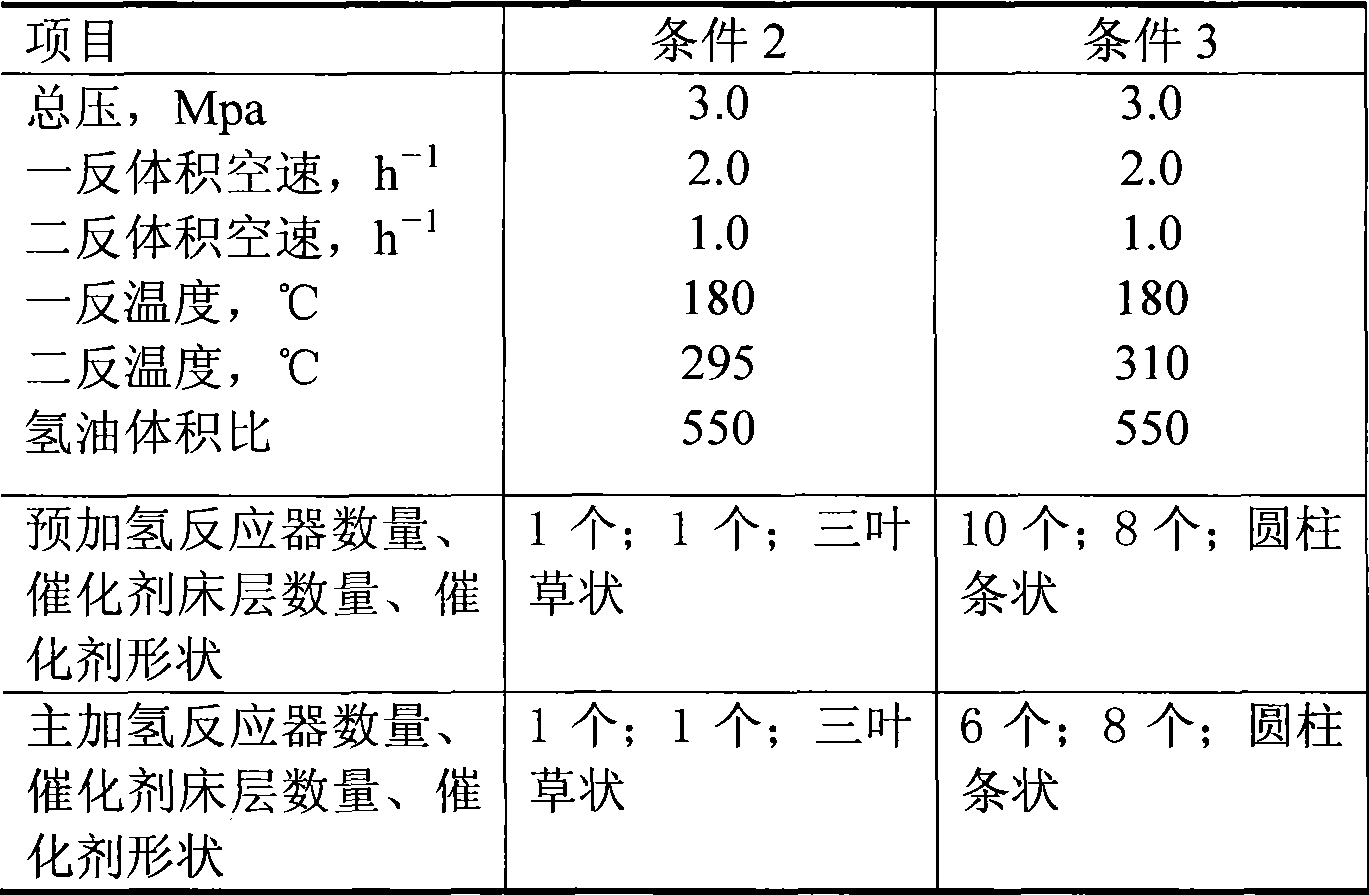

[0037] The properties of the coked crude benzene raw material used in Example 2-3 are shown in Table 1. The reaction conditions in this example are shown in Table 4 (Example 2 corresponds to Condition 2; Example 3 corresponds to Condition 3). All the other are with embodiment 1.

[0038] The properties of the processed product are shown in Table 5.

[0039] Table 4. Crude benzene hydrogenation process conditions

[0040]

[0041] Table 5. Properties of Crude Benzene Hydrogenation Products

[0042]

[0043]

[0044] Note: The hydrogenation of crude benzene is the hydrogenation of the whole distillate, and then the sulfur and nitrogen content of light benzene after cutting the real boiling point according to the dry point of 165°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com