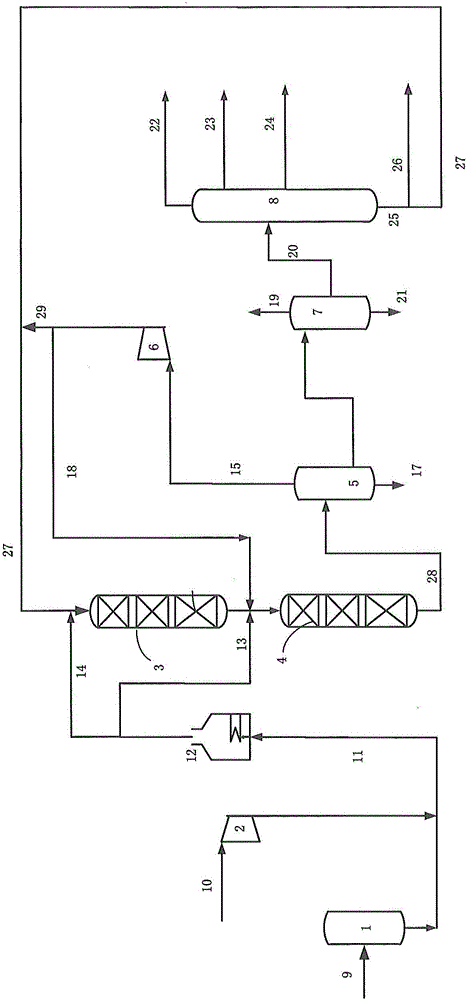

Hydrocracking method for producing middle distillates to maximum extent

A middle distillate and hydrocracking technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problem of high activity of molecular sieve hydrocracking catalyst, low reaction temperature, low yield of middle distillate, etc. problems, to achieve the effect of protecting activity and selectivity, improving yield, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] When the reaction pressure is 14.5MPa, the reaction temperature in the hydrofinishing section is 380°C, the reaction temperature in the hydrocracking section is 370°C, and the volumetric space velocity (for fresh raw materials) in the hydrofinishing section is 1.8h -1 , the volumetric space velocity of the hydrocracking section (for all feeds in the hydrocracking section) is 1.3h -1 Under the reaction conditions of the present invention, with the hydrocracking method provided by the present invention, a test was carried out using raw material A, and the ratio of RN-32V and RHC-140 catalyst filled in the hydrofinishing reactor was 3:1. The ratio of the fresh feedstock oil entering the hydrorefining reactor and the hydrocracking reactor is 9:1, and all tail oil fractions are recycled back to the hydrocracking reactor. H in the reaction atmosphere of the cracking reactor 2 S partial pressure is 0.015MPa, NH 3 The partial pressure is 0.003MPa. The test results are shown ...

Embodiment 2

[0038] When the reaction pressure is 14.5MPa, the reaction temperature in the hydrofinishing section is 380°C, the reaction temperature in the hydrocracking section is 380°C, and the volumetric space velocity (for fresh raw materials) in the hydrofinishing section is 1.8h -1 , the volumetric space velocity of the hydrocracking section (for all feeds in the hydrocracking section) is 1.3h -1 Under the reaction conditions of the present invention, with the hydrocracking method provided by the present invention, a test was carried out using raw material A, and the ratio of RN-32V and RHC-140 catalysts filled in the hydrofinishing reactor was 1:1. The ratio of fresh raw oil entering the hydrorefining reactor and the hydrocracking reactor is 4:1, and all tail oil fractions are recycled back to the hydrocracking reactor. H in the reaction atmosphere of the cracking reactor 2 S partial pressure is 0.03MPa, NH 3 The partial pressure is 0.006MPa. The test results are shown in Table 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com