Method and system for catalytic conversion of poor quality raw material oil

A catalytic conversion method and low-quality raw material oil technology are applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., and can solve the problem that the operating conditions of the hydrotreating unit are highly severe, fail to meet the specifications of commercial diesel, and affect the gasoline pool. Octane number level and other issues, to achieve the effect of increasing liquefied gas yield, reducing thermal cracking, improving raw material reaction conversion rate and target product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

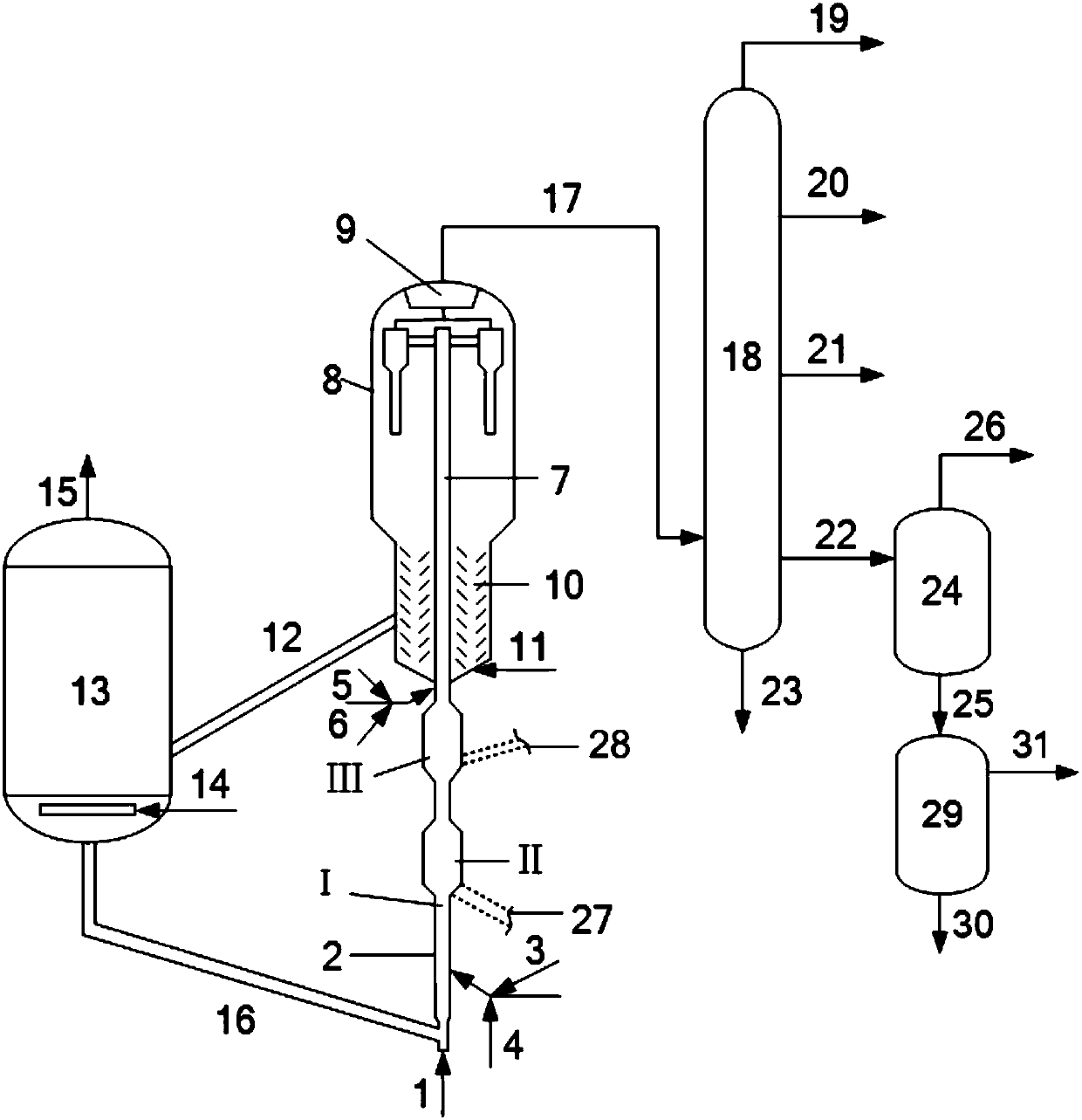

[0052] A specific embodiment, the method also includes: sending the second reaction product obtained in step b and the spent catalyst from the top outlet of the outlet section 7 to the settling section 8 for gas-solid separation, and the second reaction product obtained is sent to the settling section 8. The settling section 8 is sent to the product separation unit 18 to carry out the product separation described in step c, and the resulting raw catalyst is stripped by the stripping section 10 below the settling section 8 and then sent to the stripping section 10 and sent to the settling section 8. The regenerator 13 performs regeneration.

[0053] In order to facilitate the second reaction product and the spent catalyst from the outlet section 7 into the settling section 8, the settling section 8 and the stripping section 10 can be sleeved outside the middle and upper part of the riser reactor 2, The top outlet of the outlet section 7 may be located in the settling section 8 ...

Embodiment approach

[0064] A specific embodiment, the pre-lifting section is provided with a first regenerated catalyst inlet, the lower part of the reaction section 1 is provided with a low-quality raw material oil inlet, the middle and lower part of the outlet section 7 is provided with a high-quality raw material oil inlet, and the first The middle and lower part of a diameter-enlarging section II is provided with a semi-spent catalyst outlet, the middle and lower part of the second expanding section III is provided with a second regenerated catalyst inlet, and the top of the settling section 8 is provided with a reaction product outlet. The stripping section 10 is provided with a catalyst outlet to be produced, the reaction product outlet of the settling section 8 is in fluid communication with the raw material inlet of the product separation unit 18, and the diesel product outlet of the product separation unit 18 is connected with the aromatics extraction unit 24. The raw material inlet is in...

Embodiment

[0082] This example follows the attached figure 1 In this embodiment, vacuum residue is used as low-quality raw material oil, and hydrogenated raffinate oil is used as high-quality raw material oil. On the medium-sized device of the riser reactor (the height of the riser reactor 2 is 30 meters, the inner diameter of the pre-lift section is 0.8 meters, the height of the pre-lift section is 1.5 meters, the inner diameter of the reaction section I is 1 meter, and the inner diameter of the reaction section I is 1 meter. The height is 21 meters, the inner diameter of the first expanding section II is 3 meters, the height of the first expanding section II is 1.5 meters, the inner diameter of the reducing section is 1 meter, and the height is 1 meter, and the second expanding section III Inner diameter is 3 meters, and the height of the second enlarged diameter section III is 1.5 meters, and the inner diameter of outlet section 7 is 0.8 meters, and the height of outlet section 7 is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com