Downer reactor and catalytic conversion method

A catalytic conversion and reactor technology, which is applied in chemical instruments and methods, catalytic cracking, cracking, etc., can solve the problems of short contact time of agent oil and insufficient reaction, and achieve short contact time of agent oil, good gasoline quality, and transformation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

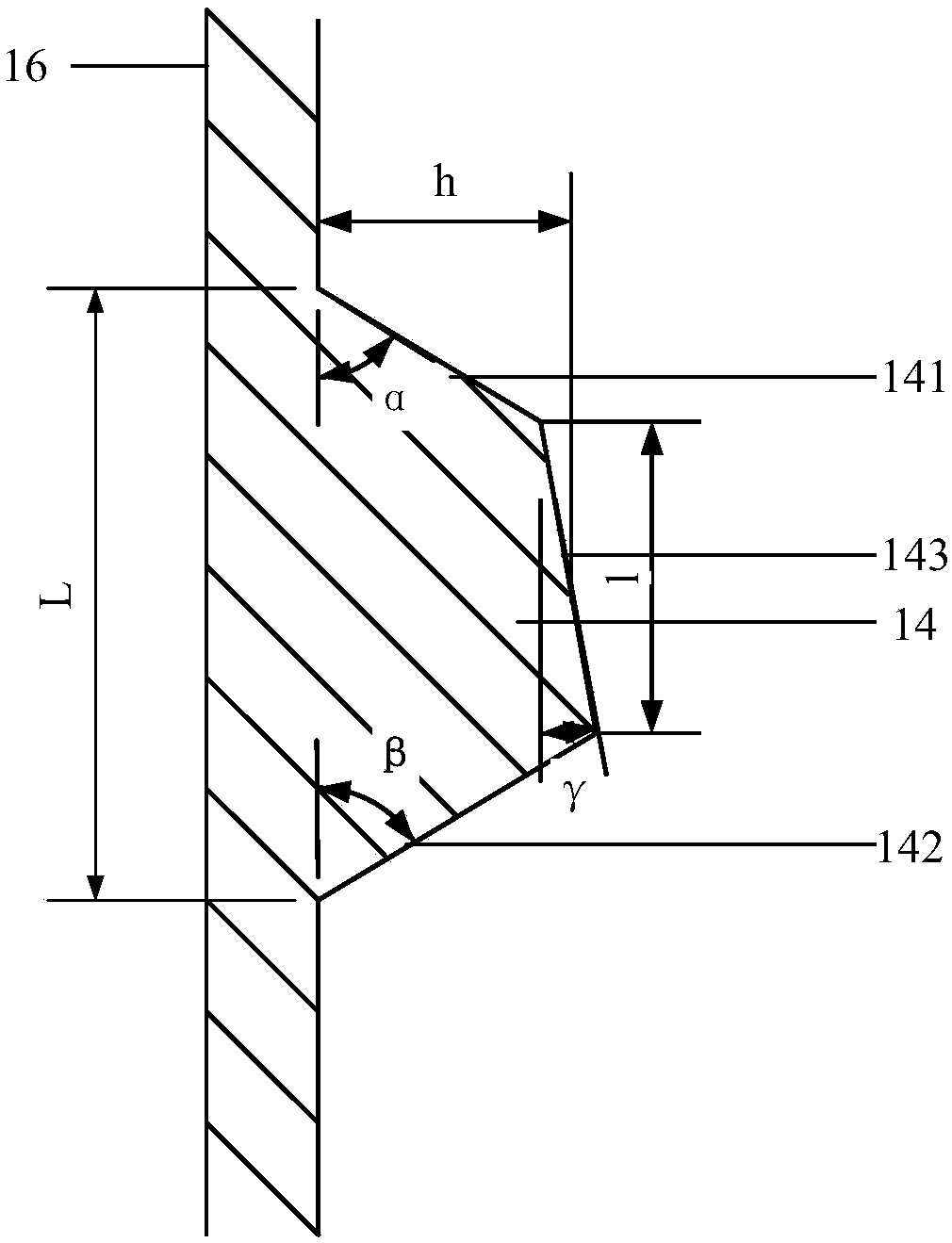

[0049] One embodiment, the top surface of the catalyst distributor 13 is a conical surface, so that the catalyst forms a uniformly dispersed annular curtain, for example, it can be a conical baffle with the tip of the cone facing upwards, and the conical baffle can be connected with the agent. The oil contact section 15 is coaxial and forms an annulus for the passage of the catalyst with the agent oil contact section 15 . The ratio of the bottom outer diameter of the catalyst distributor 13 to the agent oil contact section 15 inner diameter can be 1: (1.1-4), and the ratio of the bottom outer diameter of the catalyst distributor 13 to the height of the catalyst distributor 13 can be 1: (0.1-5).

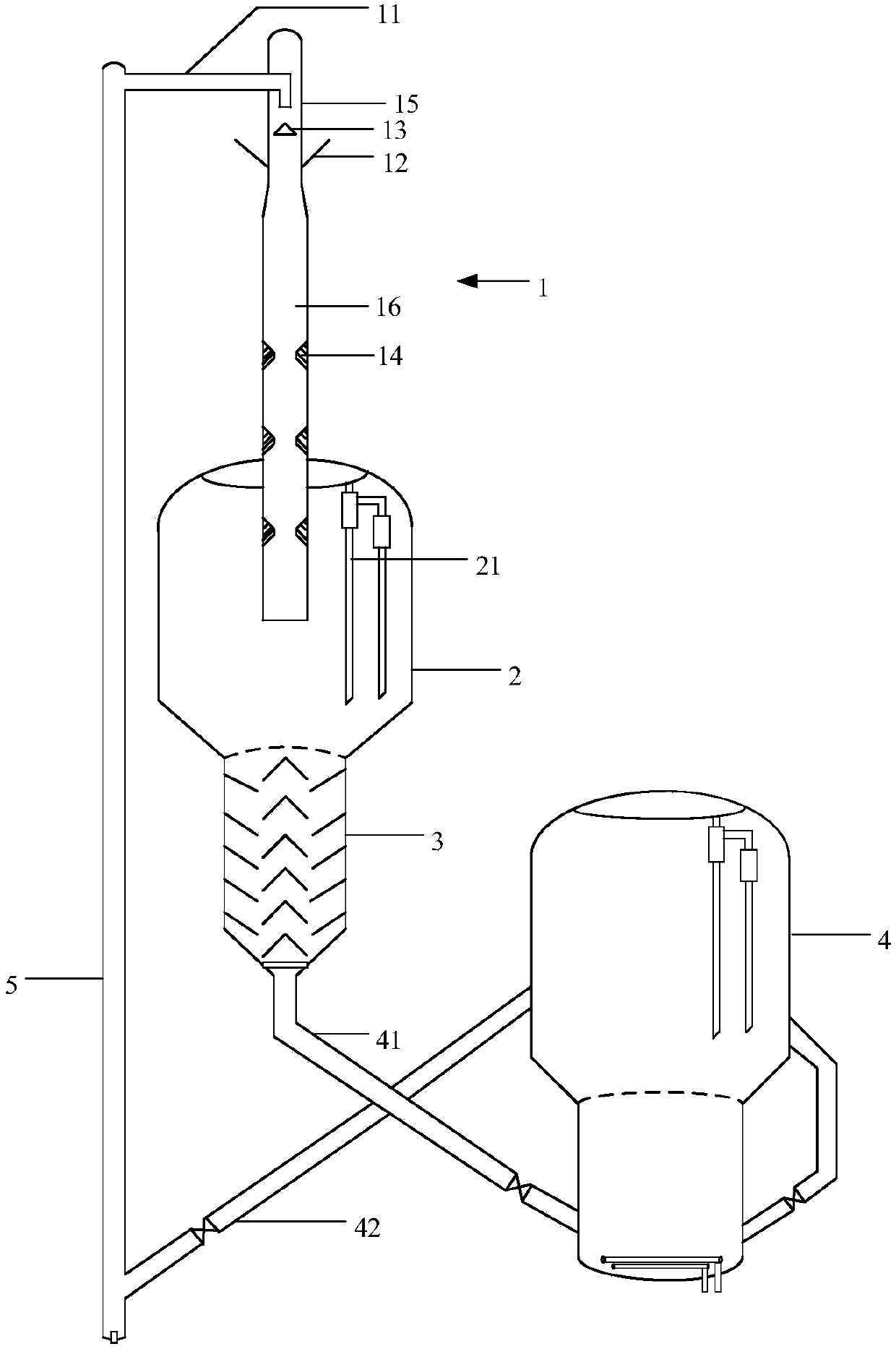

[0050] An implementation, such as figure 1 As shown, the down-flow reactor 1 is also provided with a catalyst inlet line 11, and the catalyst inlet line 11 extends from the catalyst inlet of the agent-oil contact section 15 into the agent-oil contact section 15 and makes the catalyst...

Embodiment 1

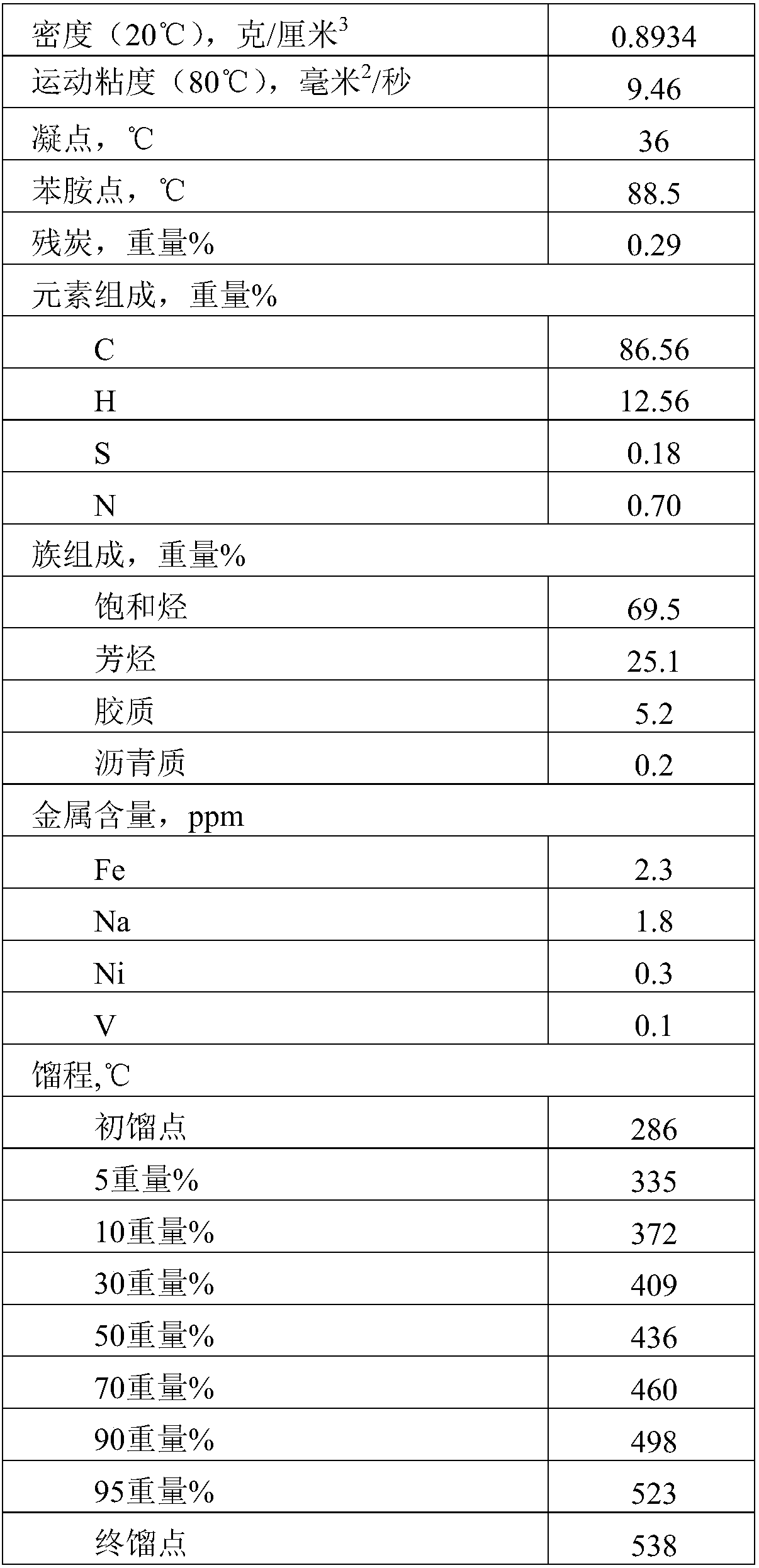

[0068] The embodiment of the present invention is to carry out on medium-scale test device, and its flow process is as follows figure 1 As shown, there is one catalyst distributor and three annular baffles in the down-flow reactor, and the main reaction section is equal in diameter. Ring baffle structure such as figure 2 As shown, α is 50°, β is 60°, γ is 15°, distance h is 0.15 of the inner diameter length of the main reaction section, the ratio of length l to distance h is 1, length l is 0.4 of length L, and an annular stop is set The length of the main reaction section of the plate accounts for 1 / 2 of the total length of the main reaction section 16, and the distance between adjacent annular baffles is equal. The catalyst distributor is a conical baffle, the ratio of the bottom outer diameter of the conical baffle to the inner diameter of the agent-oil contact section is 1:1.67, the ratio of the bottom outer diameter of the conical baffle to its height is 1:3, and the cat...

Embodiment 2

[0071] The reaction flow process of embodiment 2 is identical with embodiment 1, and the baffle plate shape parameter is identical with embodiment 1, difference is that the number of described annular baffle 13 is 5, the length of the main reaction section of setting annular baffle Accounting for 3 / 4 of the total length of the main reaction section 16, the annular baffles are arranged at equal intervals from top to bottom. The specific reaction conditions and reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com