Pretreatment method of heavy and/or inferior oil slurrybed hydrogenation upgrading iron-based catalyst

An iron-based catalyst, a technology for hydrogenation and upgrading, which is applied in the directions of hydrotreating process, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. The effect of raw material transformation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] The invention will be described below with reference to the embodiments, but the present invention is not limited thereto. And the reagents and materials used in the examples can be obtained from the business pathway as many cases.

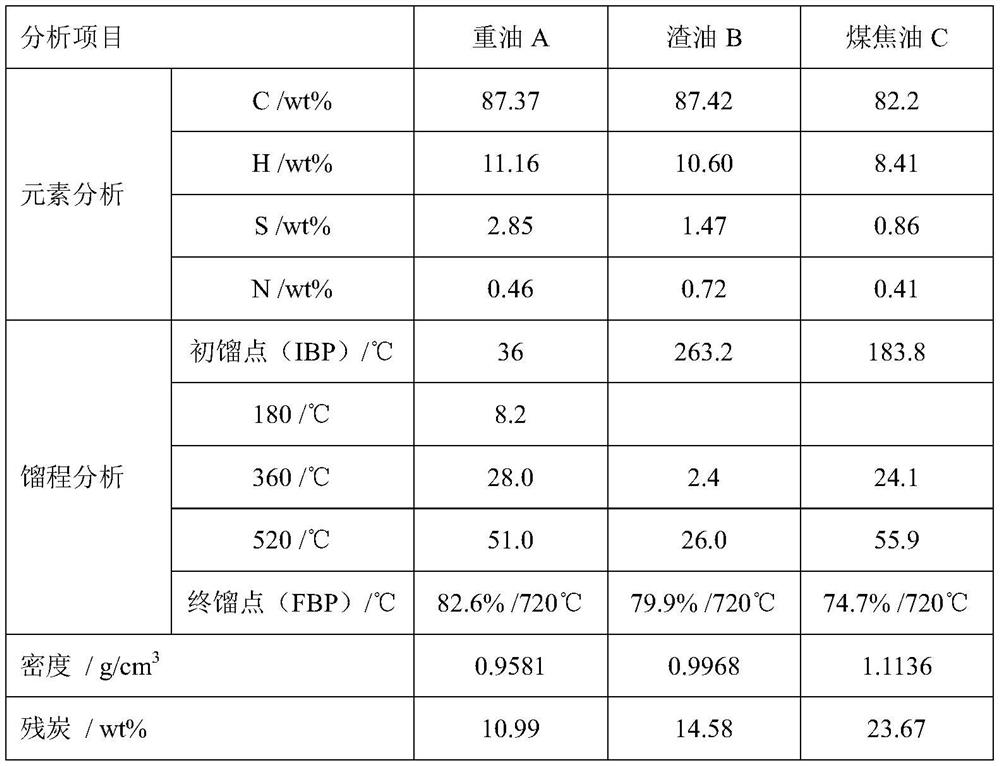

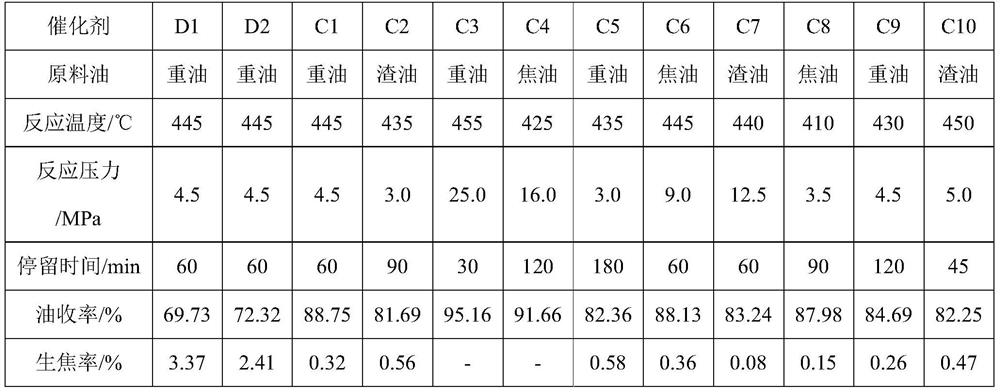

[0072] In the following examples, the catalyst and / or inferior oil matrix bed after the preprocesses obtained in the exemplary embodiment of heavy oil A, Slope B, and Coal tar C evaluate, and / or inferior oil-based catalysts. Analysis of raw material oil is shown in Table 1. Heavy and / or inferior oil Hydrogenation react conditions are shown in Table 2 below.

[0073] Table 1. Properties of raw oil

[0074]

Embodiment 1

[0081] Example 1: C1 catalyzed heavy oil hydrogenation reactions

[0082] The catalyst C1 was preprocessed using the fresh iron-based catalyst using the fresh iron-based catalyst as a fresh iron-based catalyst according to the catalyst D1 of Comparative Example 1.

[0083] 85 kg of fresh iron-based catalyst D1 and 1500 kg as a hydrothermal hydrothermal oil having a deep processing product of heavy oil hydrogenation product were mixed in a pretreatment reactor, preprocessing a mixture, wherein the fresh iron-based catalyst was prepared. The content of D1 is about 5 wt%.

[0084] Access N to the pretreatment reactor 2 Gas, replace the air in the preprocessing reactor. After the replacement is completed, the airflow pressure is adjusted to 2.2 MPa. Temperature control system, raised the temperature of the preprocessing mixture in the reactor to 280 ° C with a temperature rise rate of 0.1 ° C / min, then, the pretreatment gas flow is switched to h. 2 S concentration is 12.5 vol% h 2 S...

Embodiment 2

[0086] Example 2: C2 catalytic residue hydrogenation reaction

[0087] Catalyst C2 with auxiliary powdery Fe 2 O 3 (Auxiliary: 5WT% SIO 2 + 12WT% Al 2 O 3 + 2 wt% V + 0.5 wt% Ni) As a fresh iron-based catalyst, the fresh iron-based catalyst was preprocessed using the following procedure:

[0088] 110 g of the fresh iron-based catalyst with 390 g of Fischer-Six heavy diesel is mixed mixed in a pretreatment reactor, preprocessing the mixture, wherein the fresh iron-based catalyst is present in an amount of 22% by weight.

[0089] Top H in the pretreatment reactor 2 The mixed gas having a CO volume ratio of 2.0 is used as a pretreatment gas stream to replace the air in the pretreatment reactor. After the replacement is completed, the airflow pressure is adjusted to 3.0 MPa. The temperature control system was opened, and the temperature of the preprocessing mixture in the reactor was continuously increased to 280 ° C at a temperature rise rate of 0.3 ° C / min, and the pretreatment ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com