Method for catalyzing and cracking petroleum hydrocarbon in relaying mode

A catalytic cracking, petroleum hydrocarbon technology, applied in catalytic cracking, chemical instruments and methods, cracking, etc., can solve the problems of increased equipment renovation costs, complicated processes, and increased difficulty in device operation, and can reduce the yield of coke and dry gas. , the effect of cost reduction and temperature drop reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

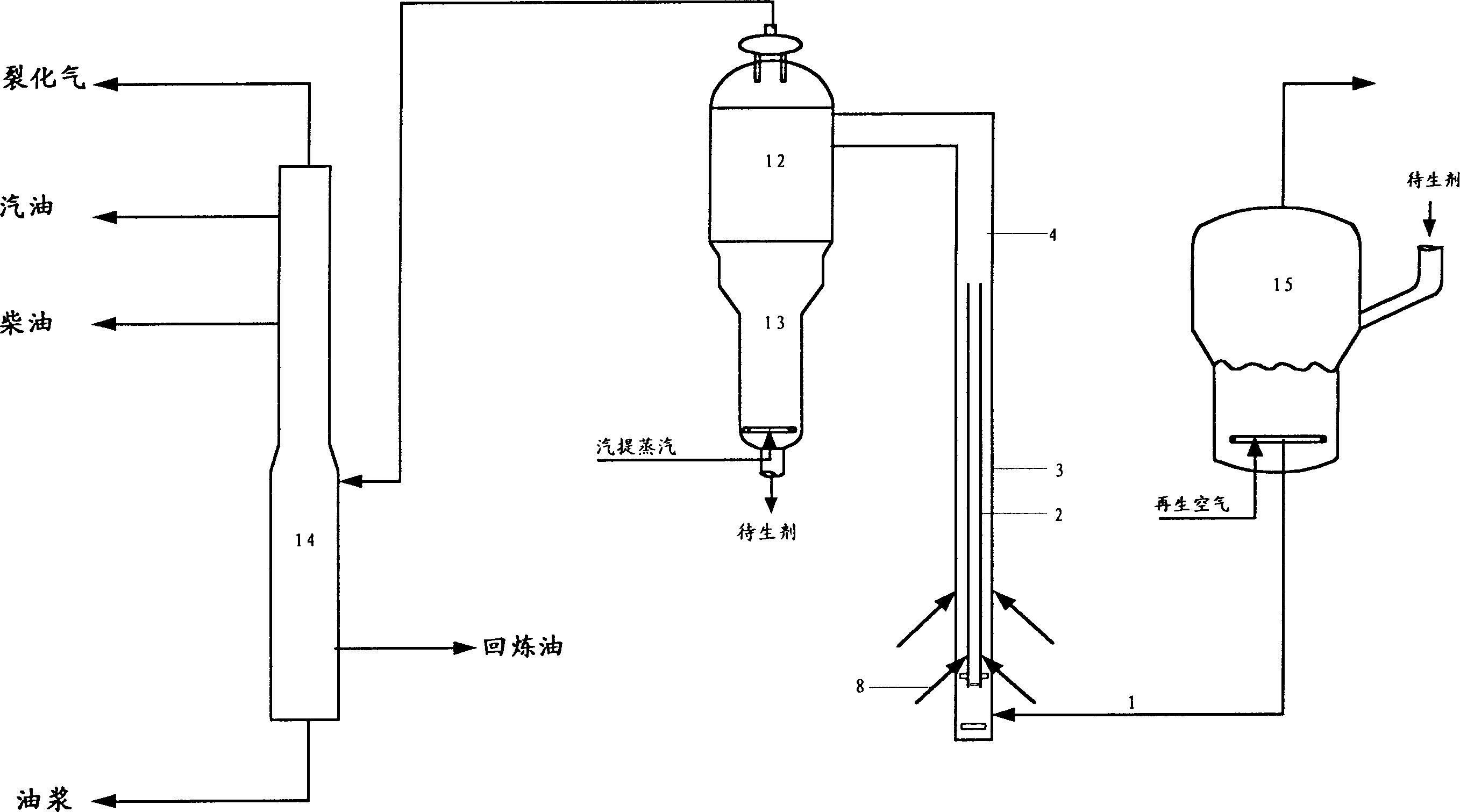

[0032] This example illustrates that using heavy petroleum hydrocarbons as raw materials, the relay cracking method provided by the present invention can obtain higher yields of liquefied gas, gasoline and diesel oil.

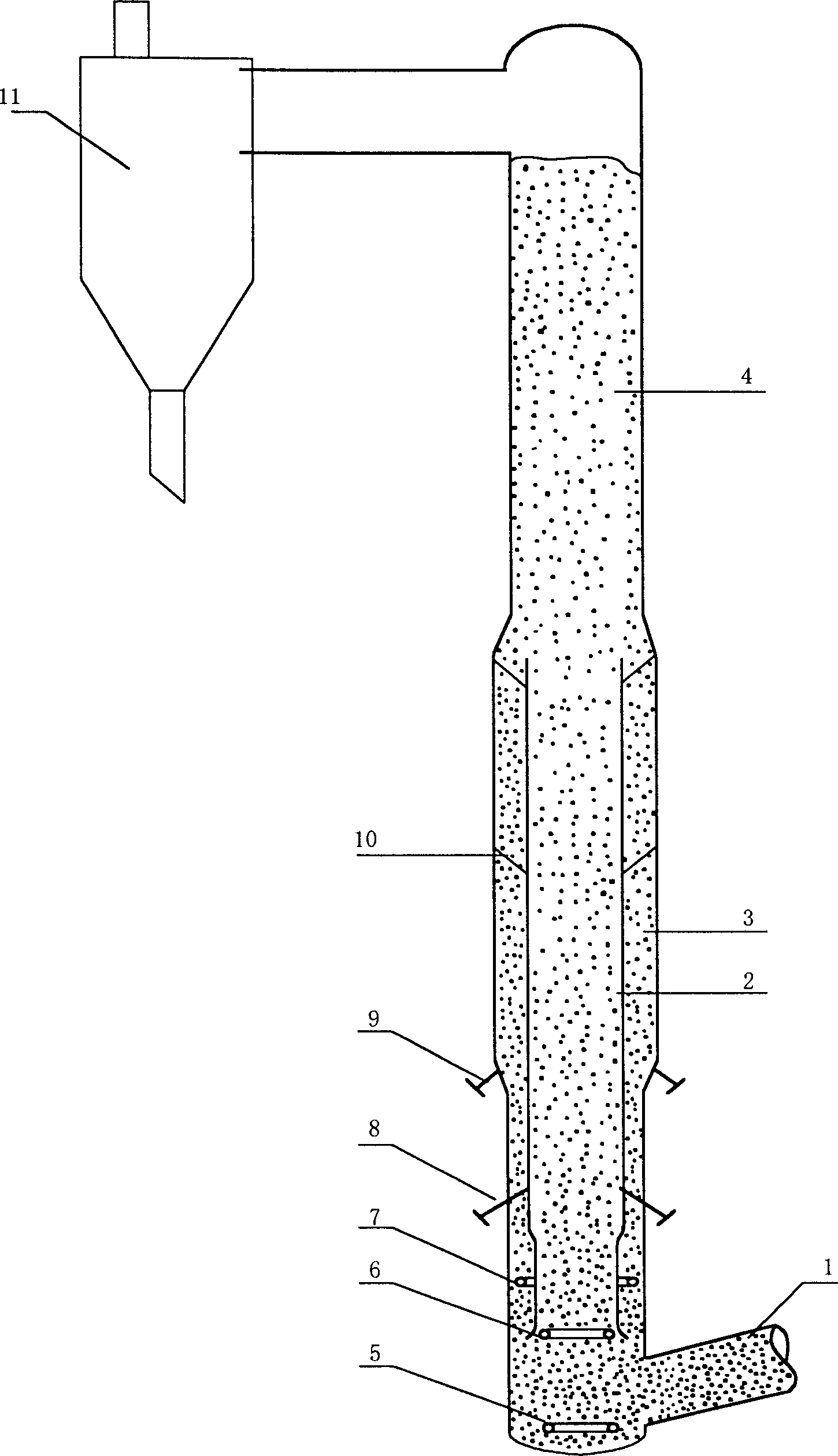

[0033] The main test steps are as follows: as shown in Figure 3, the regenerant enters the bottom of the jacketed reactor through the catalyst inlet pipe 1, and flows upward under the action of the pre-lift steam, 70% by weight of the catalyst flows into the inner pipe 2, and the rest 30% by weight of the catalyst enters the annular reaction space between the inner tube 2 and the outer tube 3, and continues to flow upwards under the action of the pre-lift steam; the raw material oil shown in Table 1 is injected into the reactor through the nozzle 8 after being preheated In the inner tube of the catalyzer, it contacts and reacts with the catalyst, and the reactant flow continues to flow upward along the wall; The regenerants in the reaction space meet and react,...

Embodiment 2

[0036] This example shows that using heavy petroleum hydrocarbons as raw materials, the relay cracking method provided by the present invention can obtain relatively high yields of propylene and other low-carbon olefins.

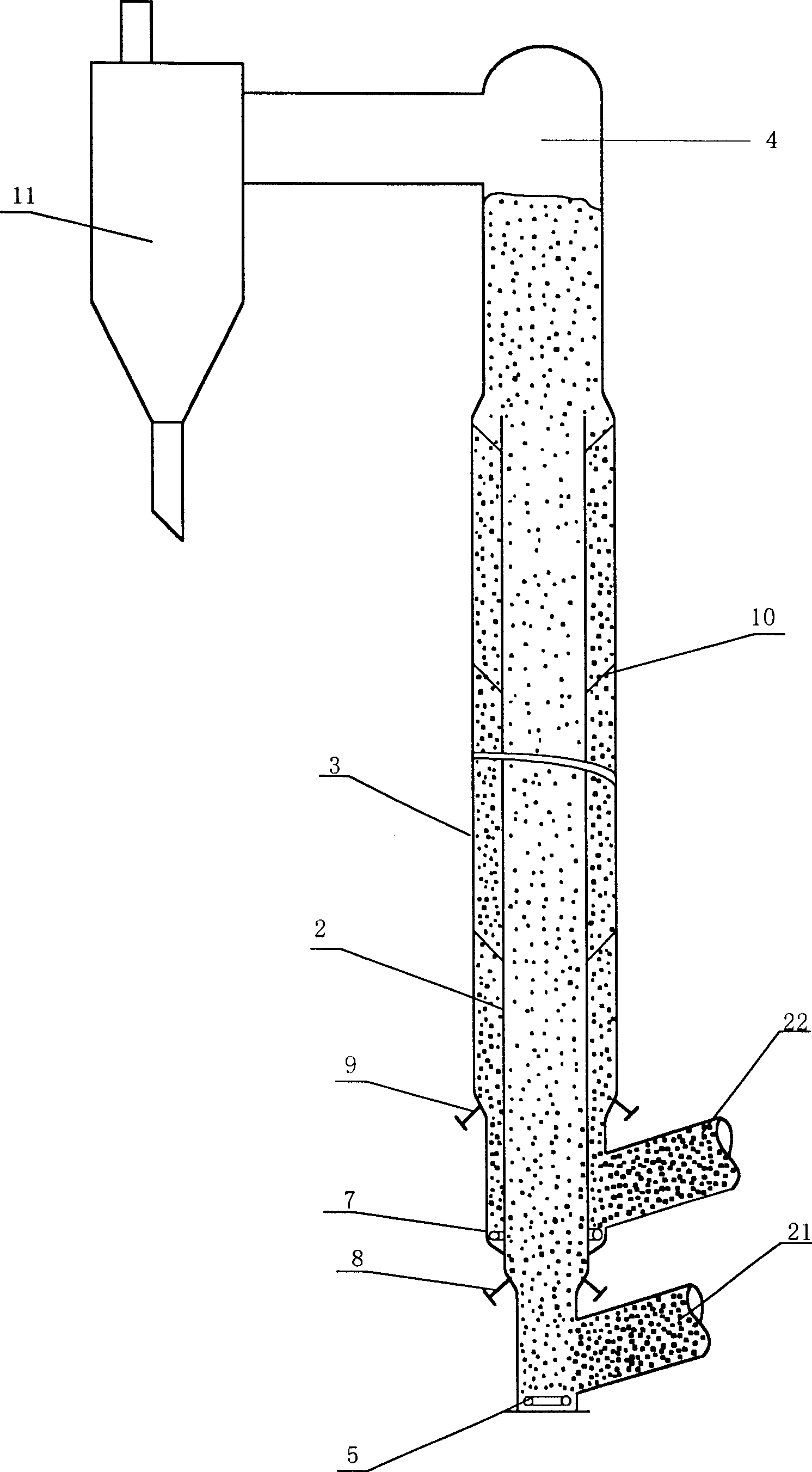

[0037] The main test steps are as follows: as shown in Figure 4, the regenerant enters the inner tube 2 of the double-path injection sleeve reactor through the catalyst inlet pipes 21 and 22, and the annular reaction space between the inner tube 2 and the outer tube 3, And it flows upward under the action of the pre-lift medium. The catalyst flowing into the inner tube accounts for 40% of the total catalyst, and the catalyst flowing into the annular space accounts for 60%. The hydrocarbon oil feedstock is injected into the inner tube of the reactor through the nozzle 8, contacts and reacts with the catalyst, and the mixture of reaction oil gas and catalyst flows upward along the wall of the reactor. The reactant flow in the inner pipe merges and reacts with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com