Engine carbon deposition cleaning agent and preparation method thereof

A carbon deposit cleaning agent and engine technology, applied in the directions of detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems of corrosion of engine parts, easy blockage of the engine, etc., and achieve fast cleaning speed and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

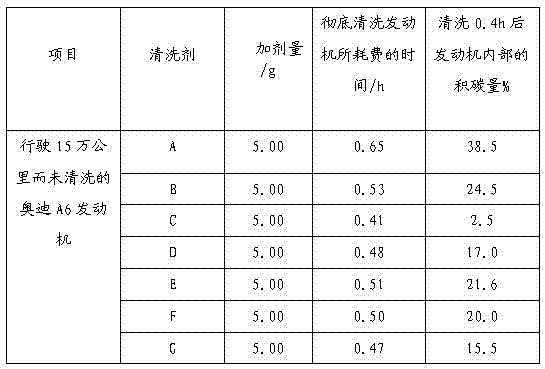

Examples

Embodiment 1

[0021] Weigh 5 parts of disodium lauryl sulfosuccinate monoester, 5 parts of sulfated castor oil, and 5 parts of polyoxyethylene methyl ether into 80 parts of toluene, heat up to 20-40°C, and add 5 parts while stirring Sulfonated oil dispersant, temperature control at 20-50°C, constant temperature reaction for 30-100min, make it dispersed into a uniform liquid, fully dissolved to obtain cleaning agent A.

Embodiment 2

[0023] Weigh 15 parts of monoethanolamide sulfosuccinic monosodium disodium DMSS, 10 parts of sodium a-alkenyl sulfonate, and 5 parts of polyoxyethylene methyl ether into 70 parts of acetone, and heat up to 20-40°C , while stirring, add 5 parts of sulfonated oil, control the temperature at 20-50°C, and react at a constant temperature for 30-100 minutes to disperse into a uniform liquid, and fully dissolve to obtain cleaning agent B.

Embodiment 3

[0025] Weigh 15 parts of monododecyl potassium phosphate MAPK, 10 parts of sodium alkylnaphthalene sulfonate, and 5 parts of polyoxypropylene methyl ether into 65 parts of ethanol, raise the temperature to 20-40°C, and add 5 parts while stirring Sulfonated oil, temperature control at 20-50°C, constant temperature reaction for 30-100min, make it dispersed into a uniform liquid, fully dissolved to obtain cleaning agent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com