Automobile engine protection liquid and preparation method thereof

A protective liquid and engine technology, applied in the field of cleaning agent, can solve the problems of inconvenient automobile engine lubrication effect, affecting engine life, etc., achieve good protection effect, good controllability, and reduce burn-in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

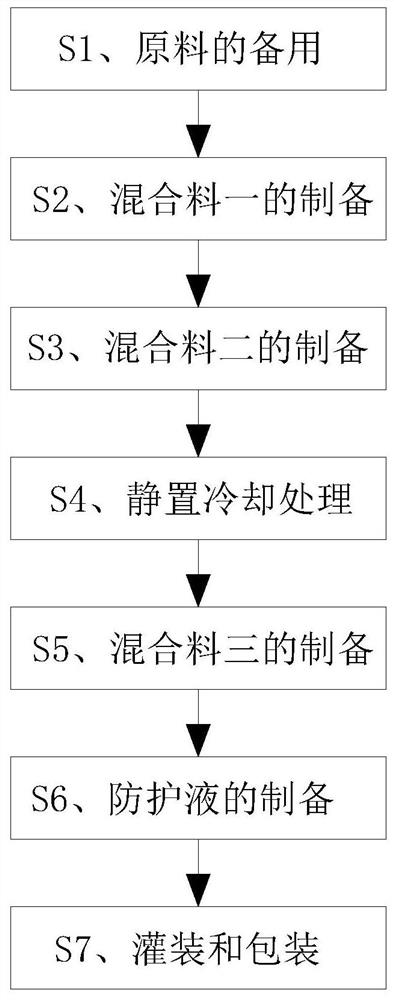

[0026] Example 1: Please refer to figure 1 As shown, the present invention discloses a protective fluid for automobile engines, comprising the following raw materials in parts by weight: 50 parts of dehydrated ions, 1 part of anionic surfactant, 3 parts of defoaming agent, 8 parts of additives, 12 parts of solvent, organic 4 parts of alkali, 5 parts of dispersant, 13 parts of modified alkyd resin, 3 parts of modified calcium lignosulfonate and 2 parts of protective agent.

[0027] A preparation method of automobile engine protective fluid, comprising the following steps:

[0028] S1, standby of raw materials: take dehydrated ion, anionic surfactant, defoamer, additive, solvent, organic base, dispersant, modified alkyd resin, modified calcium lignosulfonate and Protective agent, spare;

[0029] S2. Preparation of mixture 1: Add the deionized water in step S1 into the stirring tank to start the stirring process, add anionic surfactant and solvent to the stirring tank in turn, ...

Embodiment 2

[0035] Example 2: Please refer to figure 1 As shown, the invention discloses a protective fluid for automobile engines, comprising the following raw materials in parts by weight: 55 parts of dehydrated ions, 1.5 parts of anionic surfactants, 2 parts of defoamers, 8 parts of additives, 10 parts of solvents, organic 4 parts of alkali, 5 parts of dispersant, 13 parts of modified alkyd resin, 2 parts of modified calcium lignosulfonate and 3 parts of protective agent.

[0036] A preparation method of automobile engine protective fluid, comprising the following steps:

[0037] S1, standby of raw materials: take dehydrated ion, anionic surfactant, defoamer, additive, solvent, organic base, dispersant, modified alkyd resin, modified calcium lignosulfonate and Protective agent, spare;

[0038] S2. Preparation of mixture 1: Add the deionized water in step S1 into the stirring tank to start the stirring process, add anionic surfactant and solvent to the stirring tank in turn, stir at r...

Embodiment 3

[0044] Example 3: Please refer to figure 1 As shown, the present invention discloses a protective fluid for automobile engines, comprising the following raw materials in parts by weight: 60 parts of dehydrated ions, 1.5 parts of anionic surfactants, 2 parts of defoamers, 5 parts of additives, 10 parts of solvents, organic 3 parts of alkali, 5 parts of dispersant, 13 parts of modified alkyd resin, 3 parts of modified calcium lignosulfonate and 3 parts of protective agent.

[0045] A preparation method of automobile engine protective fluid, comprising the following steps:

[0046] S1, standby of raw materials: take dehydrated ion, anionic surfactant, defoamer, additive, solvent, organic base, dispersant, modified alkyd resin, modified calcium lignosulfonate and Protective agent, spare;

[0047] S2. Preparation of mixture 1: add the deionized water in step S1 into the stirring tank to start the stirring process, add anionic surfactant and solvent to the stirring tank in turn, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com