Low carbon alkane dehydrogenation catalyst and preparation method thereof

A low-carbon alkane and catalyst technology, which is applied to the catalyst and preparation field of a low-carbon alkane dehydrogenation catalyst, can solve the problems of poor catalyst stability, easy coke deactivation of the catalyst, slow deactivation rate of the catalyst coke, and the like. Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

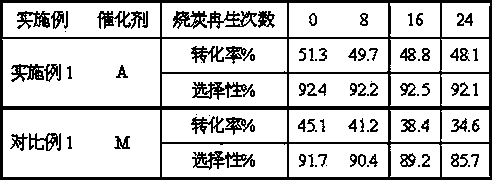

Embodiment 1

[0026] In 430.7g of pseudo-boehmite raw powder main material, add 12.9g of turnip powder and mix evenly, then add 150 ml of mixed solution containing catalyst active components, including 2.9g of sodium nitrate; 2.3g of zinc nitrate, knead fully and squeeze The strips were placed at room temperature for 12 hours, then kept at 90°C for 3 hours, and then dried at 120°C for 10 hours, pelletized and treated at 750°C to obtain a composite carrier containing catalytic promoters.

[0027] The composite alumina carrier obtained adopts impregnation technology to load the platinum-tin component, namely at room temperature with the alumina carrier impregnated with the required amount of chloroplatinic acid-tin tetrachloride (3.15g chloroplatinic acid; 6.4g crystallization tin tetrachloride) mixed aqueous solution for 24 hours, then 60 oC drying, in air stream 530 oC Roast for 3 hours, then steam at 530 oC Under treatment for 4 hours, ultimatum dry air 530 oC Treat for 1 hour to ob...

Embodiment 2

[0030] In 430.1g of pseudo-boehmite raw powder main material, add 12.3g of turnip powder and mix evenly, then add 150 ml of mixed solution containing catalyst active components, including 2.9g of sodium nitrate; 3.7g of zinc nitrate, knead fully and squeeze The strips were placed at room temperature for 12 hours, then kept at 90°C for 3 hours, and then dried at 120°C for 10 hours, pelletized and treated at 750°C to obtain a composite carrier containing catalytic promoters.

[0031] The composite alumina carrier obtained adopts impregnation technology to load the platinum-tin component, namely at room temperature with the alumina carrier impregnated with the required amount of chloroplatinic acid-tin tetrachloride (3.15g chloroplatinic acid; 6.4g crystallization tin tetrachloride) mixed aqueous solution for 24 hours, then 60 oC drying, in air stream 530 oC Roast for 3 hours, then steam at 530 oC Under treatment for 4 hours, ultimatum dry air 530 oC Treat for 1 hour to ob...

Embodiment 3

[0034] In 429.8g of pseudo-boehmite raw powder main material, add 12.8g of scallop powder and mix evenly, then add 150 ml of mixed solution containing catalyst active components, including 1.6g of sodium nitrate; 2.1g of zinc nitrate, knead fully and squeeze The strips were placed at room temperature for 12 hours, then kept at 90°C for 3 hours, and then dried at 120°C for 10 hours, pelletized and treated at 750°C to obtain a composite carrier containing catalytic promoters.

[0035] The composite alumina carrier obtained adopts impregnation technology to load the platinum-tin component, that is, at room temperature, impregnates the required amount of chloroplatinic acid-tin tetrachloride (3.42g chloroplatinic acid; 5.4g crystallization tin tetrachloride) mixed aqueous solution for 24 hours, then 60 oC drying, in air stream 530 oC Roast for 3 hours, then steam at 530 oC Under treatment for 4 hours, ultimatum dry air 530 oC Treat for 1 hour to obtain a catalyst sample, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com