Method for improving selectivity of light olefin hydrocarbon

A technology of light olefins and reactors, applied in chemical instruments and methods, chemical recovery, ethylene production, etc., can solve the problems of low yield of light olefins and low added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

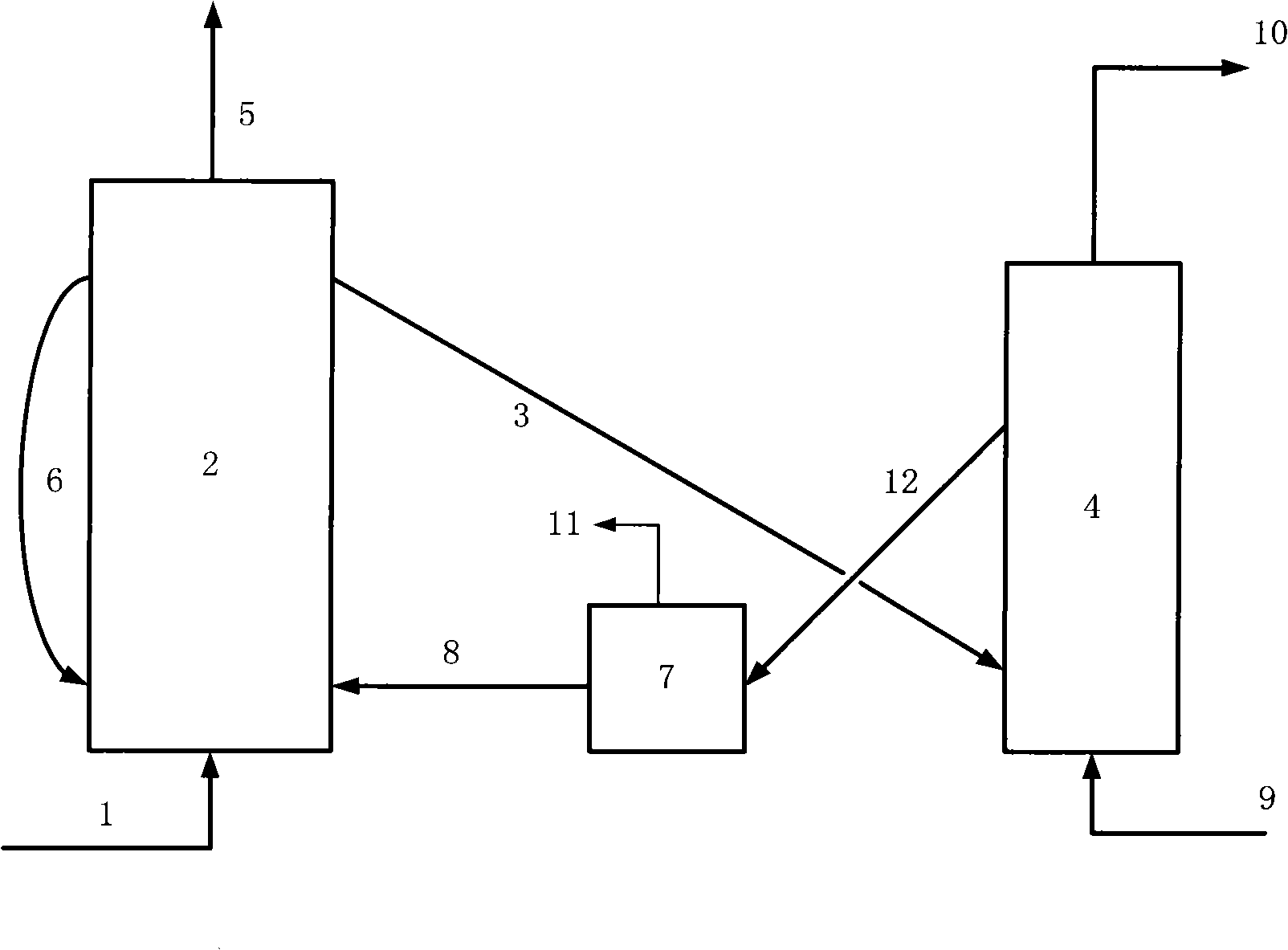

[0022] The first reactor is a small fast fluidized bed, fed with pure methanol, the catalyst type is shown in Table 1, the average temperature of the reaction zone is 500°C, and the methanol weight hourly space velocity is 25 hours -1 , the reaction pressure is 0.1MPa in gauge pressure. 40% by weight of the carbon-deposited catalyst enters the regenerator for regeneration, and the carbon content of the regenerated catalyst is 0.2% by weight, and enters the second reactor to contact and react with raw materials including methanol and ethylene, wherein the properties of methanol are the same as those of the first reactor. It enters the second reactor in liquid form, the weight ratio of methanol to ethylene is 0.01:1, and the second reactor is a riser. Catalyst carbon deposition amount after reaction in the second reactor is 0.5% weight, then enters first reactor through pipeline 8, mixes with remaining part carbon deposition catalyst that returns through pipeline 6, the catalyst...

Embodiment 5~6

[0026] According to the conditions described in Example 4, the reaction temperature, reactor type and corresponding space velocity of the first reactor were changed, and the experimental results are shown in Table 2.

[0027] Table 2

[0028]

Embodiment 7~9

[0030] According to the conditions described in Example 4, only the raw material type, raw material weight hourly space velocity, and reaction pressure of the first reactor were changed. The experimental results are shown in Table 3.

[0031] table 3

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com