Combined catforming of high-production low carbon alkene

A catalytic conversion method and technology of low-carbon olefins, which are applied in the fields of hydrocarbon cracking to produce hydrocarbons, chemical recovery, organic chemistry, etc. , easy desorption, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

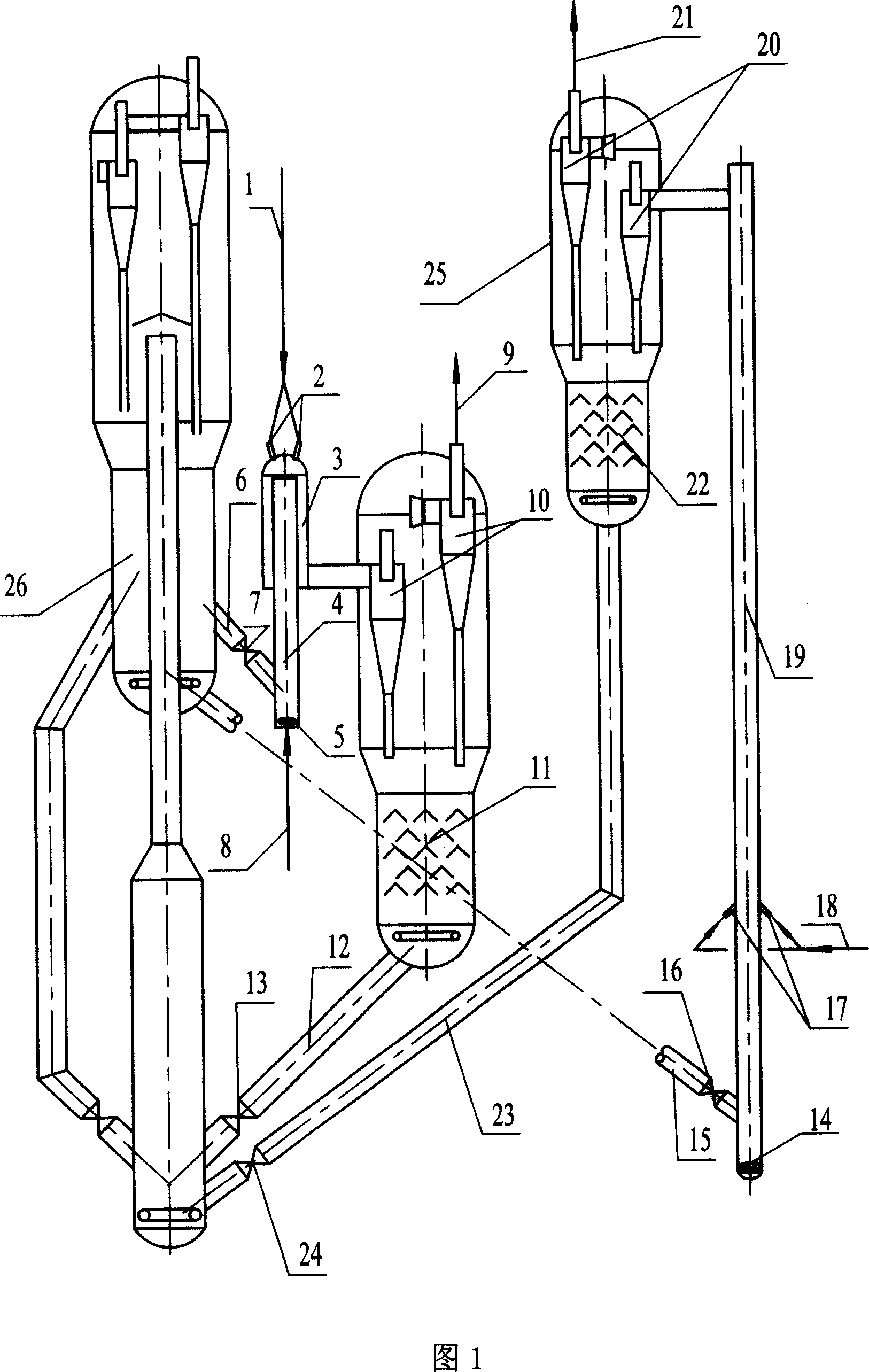

[0032] As shown in Figure 1, the first stream of regenerated catalyst at about 720 °C enters the pre-lift section 4 of the downcomer reactor through the delivery pipeline 6 and the flow control valve 7, and the pre-lift medium from the pipeline 8 enters the pre-lift section through the distributor 5 4. Lift the catalyst in the pre-lift section 4 to the inlet of the downcomer reactor 3 . The pre-lifting medium can be water vapor, dry gas from or outside the device, C4 components in cracked gas or a mixture of these gases. The preheated heavy oil raw material is injected into the downcomer reactor 3 through the pipeline 1 and the nozzle 2 after being atomized by atomized water vapor, and then contacts and reacts with the hot catalyst from the catalyst pre-lifting section 4 . The reaction temperature is 500-650°C, preferably 520-620°C; the reaction pressure is 1.5-5×10 5 Pa, preferably 1.8-4×10 5 Pa; the reaction time is 0.1-1.5 seconds, preferably 0.15-1 seconds; the weight fl...

Embodiment approach 2

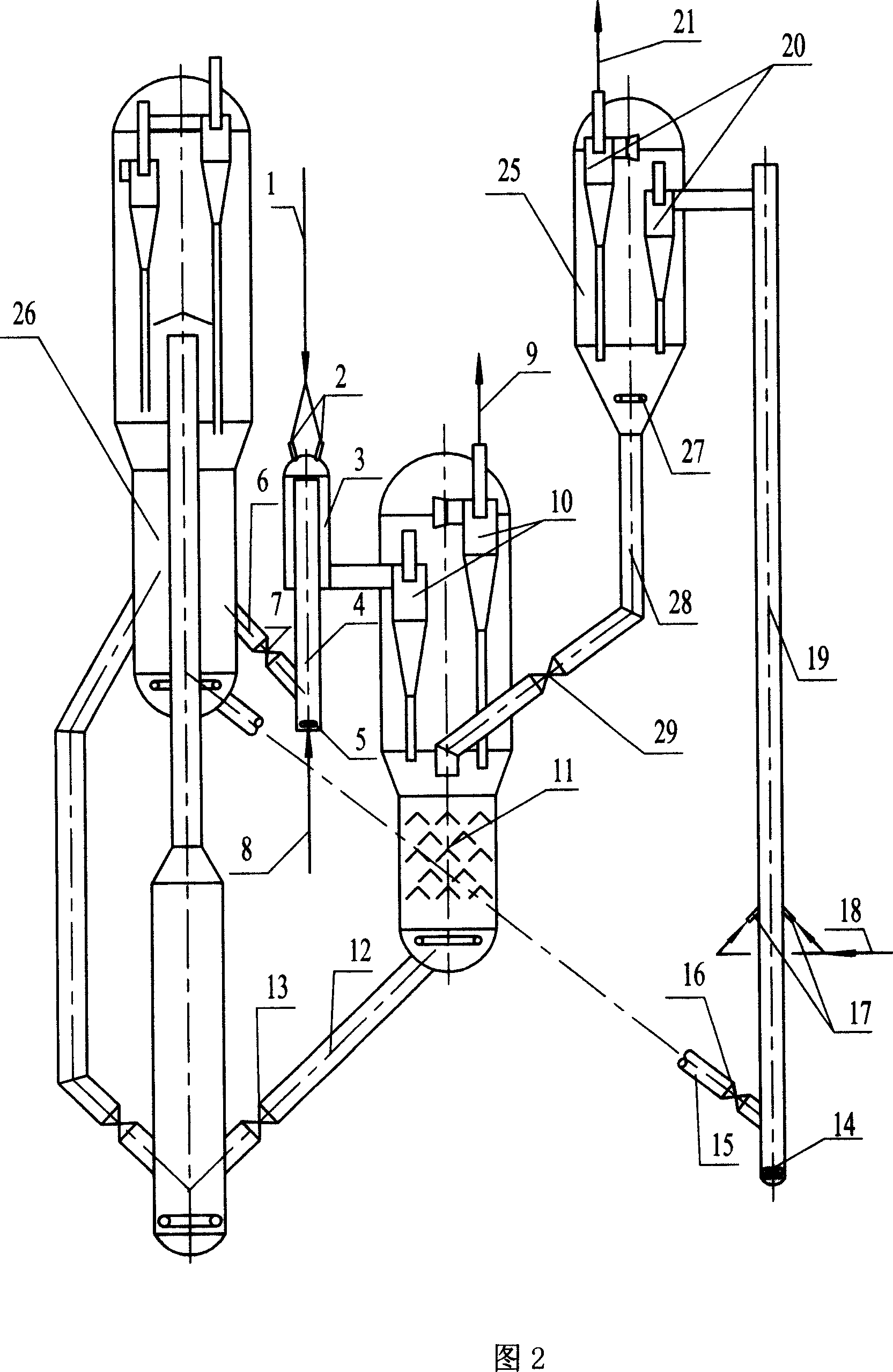

[0035] Figure 2 shows a second embodiment of the present invention. The difference between this embodiment and the first embodiment is that the catalyst separated by the gas-solid separation device 20 at the outlet of the riser does not directly enter the catalyst regeneration system after being pre-stripped by the water vapor injected by the distribution pipe 27 at the lower part of the settler 25 , but enter the stripper 11 below the gas-solid separation system of the downcomer reactor through the delivery pipeline 28 and the catalyst flow control valve 29, and after mixing with the catalyst collected by the gas-solid separation system of the downcomer reactor, they are together in the stripper 11 accepts water vapor stripping, and then enters the regenerator through the delivery pipeline 12 and the catalyst flow control valve 13 and returns to the reaction system for recycling. Because the reaction temperature of the riser is higher than the reaction temperature of the down...

Embodiment approach 3

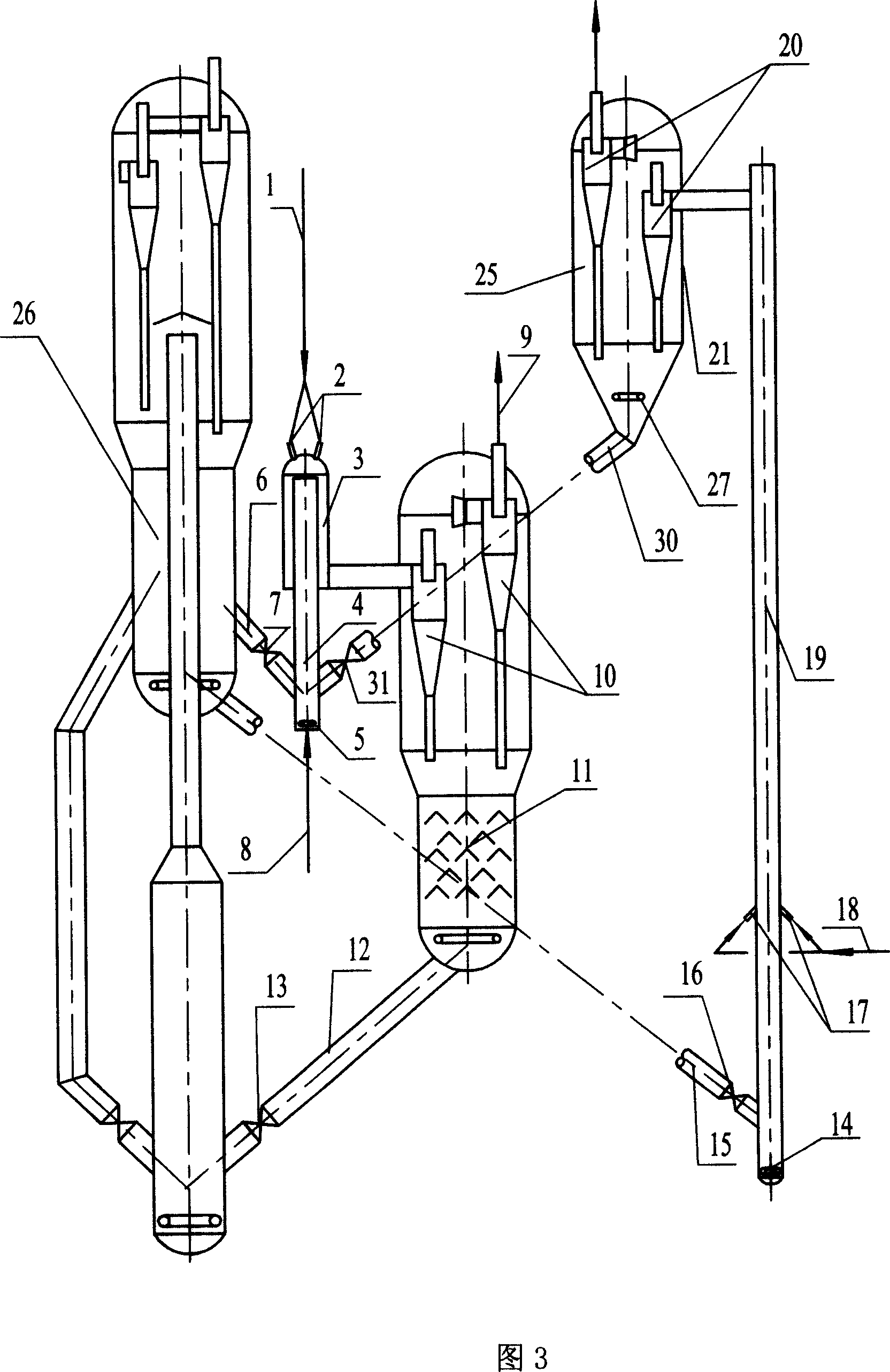

[0037] Fig. 3 shows a third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the catalyst separated by the gas-solid separation device 20 at the outlet of the riser does not directly enter the catalyst regeneration system after being pre-stripped by the water vapor injected by the distribution pipe 27 at the lower part of the settler 25 , but enters the catalyst pre-lift section 4 of the downcomer reactor through the pipeline 30 and the catalyst flow control valve 31. Reactor feed oil contact. Because the raw material for the riser reaction is relatively light and the reaction temperature is relatively high, the catalyst after the reaction has less carbon deposits and still has a relatively high activity and temperature. Introducing this catalyst into the downcomer not only helps to increase the catalyst-oil ratio of the downcomer reaction, but also increases the contact opportunity between the heavy oil feedstock an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com