Demetallization catalyst of addig hydrogen to residual oil and preparation method

A technology of residual oil hydrogenation and catalyst, applied in refining to remove heteroatoms, etc., can solve the problem of high carbon deposition, achieve the effect of reduced carbon deposition and high hydrodemetallization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

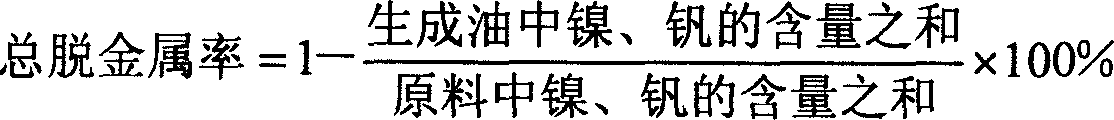

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Take by weighing the dry rubber powder (dry basis is 73% that Changling Oil Refinery Catalyst Factory produces, and wherein pseudo-boehmite content is 68 weight %, and gibbsite content is 5 weight %, and remainder is amorphous alumina) 300 grams, 9 grams of fennel powder (product of Lankao Tianjing Rubber Factory in Henan Province) are mixed, then add 360 milliliters of aqueous solution containing 12 grams of ammonium fluoride (product of Tianjin Chemical Reagent No. 3 Factory), and extrude into φ 1. 1 mm trefoil strips, wet strips were dried at 120°C for 4 hours and then calcined at 700°C for 2 hours to obtain carrier Z1. The acid content, fluorine content, specific surface area, accessible pore size, pore distribution and pore volume of Z1 were measured, and the results are shown in Table 1.

[0033] The fluorine content is determined by X-ray fluorescence spectrometry, and the specific surface area, programmable pore size, pore distribution and pore volume are determ...

example 2

[0043] Take by weighing 300 grams of dry rubber powder (with example 1), 12 grams of polyvinyl alcohol (Changling Catalyst Factory) mixes, then add 360 milliliters of solutions containing 18 grams of hydrofluoric acid (Beijing Chemical Plant product), and extrude in twin-screw Extruded on the machine into a Raschig ring strip with an outer diameter of 3.5 mm and an inner diameter of 1.0 mm, the wet strip was dried at 150°C for 2 hours and then calcined at 780°C for 2 hours to obtain carrier Z2. The acid content, fluorine content, specific surface area, probable pore diameter, pore distribution and pore volume of Z2 were measured, and the results are shown in Table 1.

example 3

[0045] Take by weighing aluminum hydroxide powder (dry basis is 74% on a dry basis, wherein pseudo-boehmite content is 82% by weight, gibbsite content is 5% by weight, and surplus is amorphous aluminum oxide) 300 grams produced by Shanxi Aluminum Factory , 9 grams of scallop powder and 9 grams of methyl cellulose are mixed, and then 360 ml of aqueous solution containing 5 grams of ammonium fluoride is added, extruded into a butterfly-shaped strip of φ1.5 mm on a twin-screw extruder, and the wet strip is subjected to 120°C After drying for 4 hours, keep the temperature at 750° C. for 2 hours to obtain carrier Z3. The acid content, fluorine content, specific surface area, probable pore diameter, pore distribution and pore volume of Z3 were measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com