Hydrophilic ice-cold skin touch finishing agent for cotton fabric and preparation method of hydrophilic ice-cold skin touch finishing agent

A hydrophilic, finishing agent technology, used in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of poor fabric hand and washability, and decreased softness performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 A kind of cotton fabric hydrophilic type cooling skin feeling finishing agent

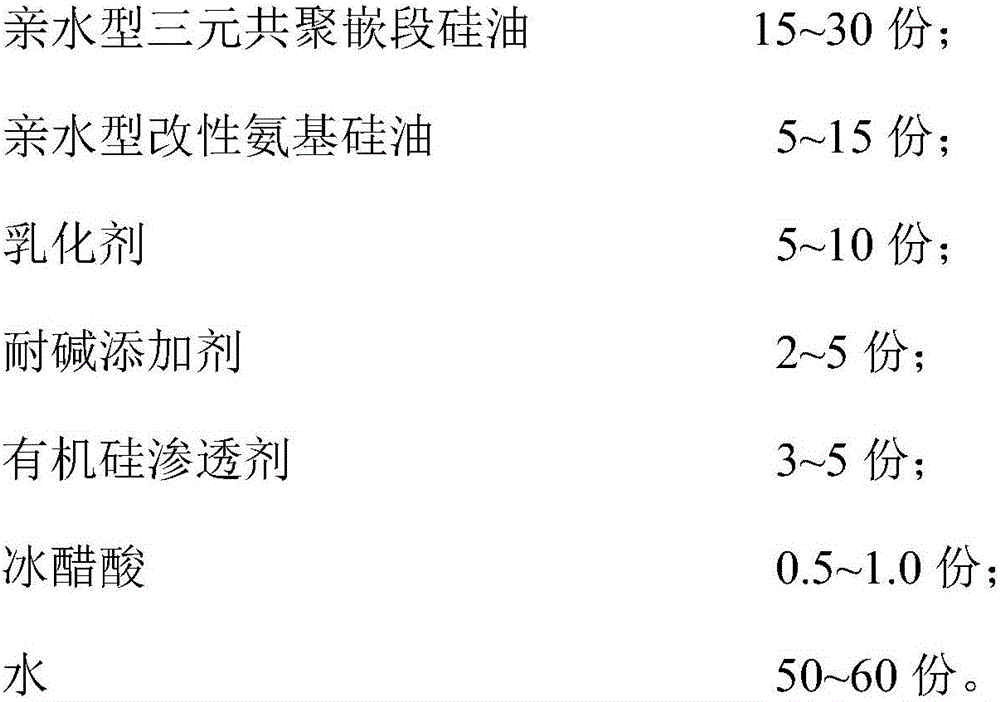

[0063] The hydrophilic type cooling skin feeling finishing agent for cotton fabrics of the present embodiment, its raw material formula is made up of each component of following parts by weight:

[0064]

[0065]

[0066] The preparation method of the above-mentioned hydrophilic type ternary copolymerization block silicone oil comprises the following steps:

[0067] step 1

[0068] Put hydrogen-containing silicone oil with a molecular weight of 10000, allyl epoxy polyether and isopropanol with a molecular weight of 600 into the reaction kettle, and heat up to 80° C., and react for 4 hours to prepare epoxy-terminated polyether silicone oil; The reaction molar ratio of terminal hydrogen-containing silicone oil and allyl epoxy polyether is 1:2; the consumption of described isopropanol is 40% of reactant gross weight;

[0069] step 2

[0070] React the epoxy-terminated poly...

Embodiment 2

[0085] Embodiment 2 A kind of cotton fabric hydrophilic type cooling skin feeling finishing agent

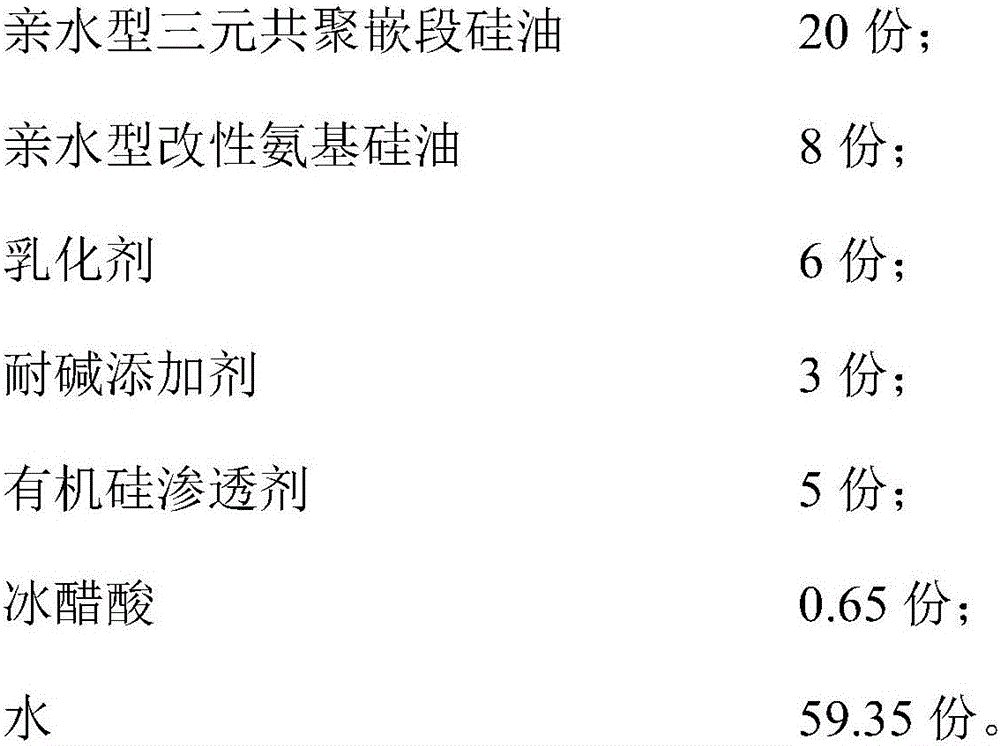

[0086] The hydrophilic type cooling skin feeling finishing agent for cotton fabrics of the present embodiment, its raw material formula is made up of each component of following parts by weight:

[0087]

[0088] The preparation method of the above-mentioned hydrophilic type ternary copolymerization block silicone oil comprises the following steps:

[0089] step 1

[0090] Put hydrogen-containing silicone oil with a molecular weight of 13000, allyl epoxy polyether and isopropanol with a molecular weight of 400 into the reaction kettle, and heat up to 80° C., and react for 6 hours to prepare epoxy-terminated polyether silicone oil; The reaction molar ratio of terminal hydrogen-containing silicone oil and allyl epoxy polyether is 1:2.2; The consumption of described Virahol is 40% of reactant gross weight;

[0091] step 2

[0092] React the epoxy-terminated polyether silicone...

Embodiment 3

[0107] Embodiment 3 A kind of cotton fabric hydrophilic type cooling skin feeling finishing agent

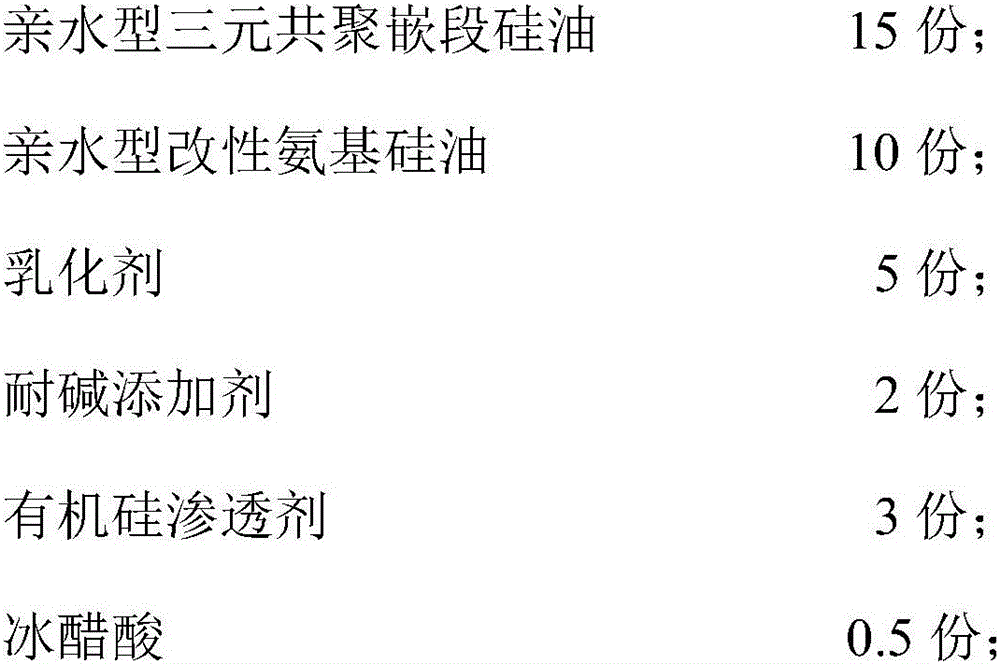

[0108] The hydrophilic type cooling skin feeling finishing agent for cotton fabrics of the present embodiment, its raw material formula is made up of each component of following parts by weight:

[0109]

[0110] The preparation method of the above-mentioned hydrophilic type ternary copolymerization block silicone oil comprises the following steps:

[0111] step 1

[0112] Add hydrogen-containing silicone oil with a molecular weight of 10000, allyl epoxy polyether and isopropanol with a molecular weight of 1000 into the reaction kettle, and raise the temperature to 80° C., and react for 7 hours to prepare epoxy-terminated polyether silicone oil; The reaction molar ratio of terminal hydrogen-containing silicone oil and allyl epoxy polyether is 1:2.5; the consumption of described isopropanol is 55% of reactant total amount;

[0113] step 2

[0114] React the epoxy-terminated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com