Emulsion composition, method for softening fiber structure and fiber containing base material

A technology of emulsion composition and fiber base material, applied in fiber treatment, non-fiber pulp addition, fiber raw material treatment, etc., can solve the problems of natural and beneficial property damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

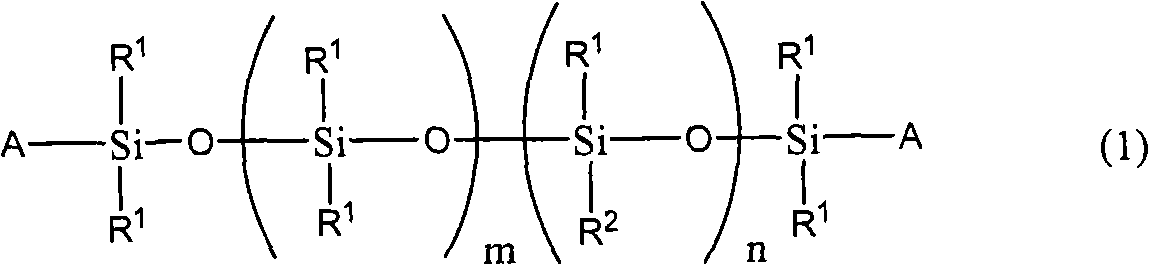

Method used

Image

Examples

Embodiment

[0133] The present invention is described in more detail with reference to Examples and Comparative Examples, but it should be understood that these Examples should not limit the scope of the present invention.

[0134] [Average particle size of emulsion particles]

[0135] Emulsion particles were measured using a submicron particle analyzer (product of Malvern Instruments Co. Ltd.; Mastersizer 2000) for measuring submicron-sized particles by laser diffraction average particle size.

[0136] [Viscosity of organopolysiloxane]

[0137] The viscosity of the organopolysiloxane was measured using a Brookfield Engineering Laboratories rotational viscometer (trademark: Brookfield DV-III super type); measurement stability: 25°C.

[0138] [Appearance of emulsion composition]

[0139] The appearance of the emulsion composition was evaluated by visual observation. Use the following criteria.

[0140] ◎Completely transparent

[0141] ○ Transparent with some cloudiness (i.e. transluc...

Embodiment 7

[0156] Tissue (2) is a commercially available tissue product (as a target reference),

[0157] Tissue paper (3) is a crude tissue paper substrate that has not been treated with any emulsion (as a blank).

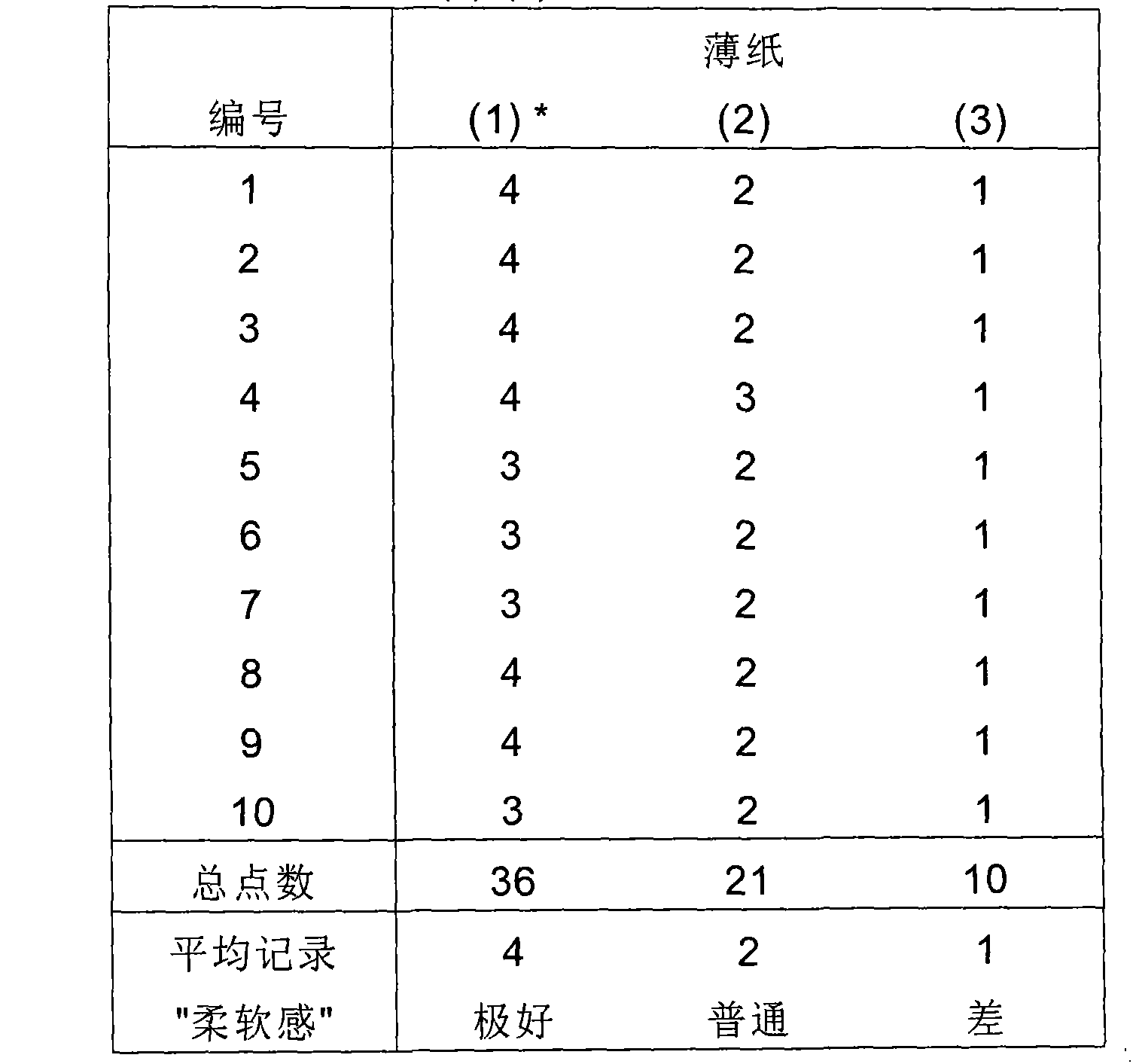

[0158] Table: Hand properties of "soft feel" for tissue papers (1)-(3)

[0159]

[0160] * Equivalent to working example 7.

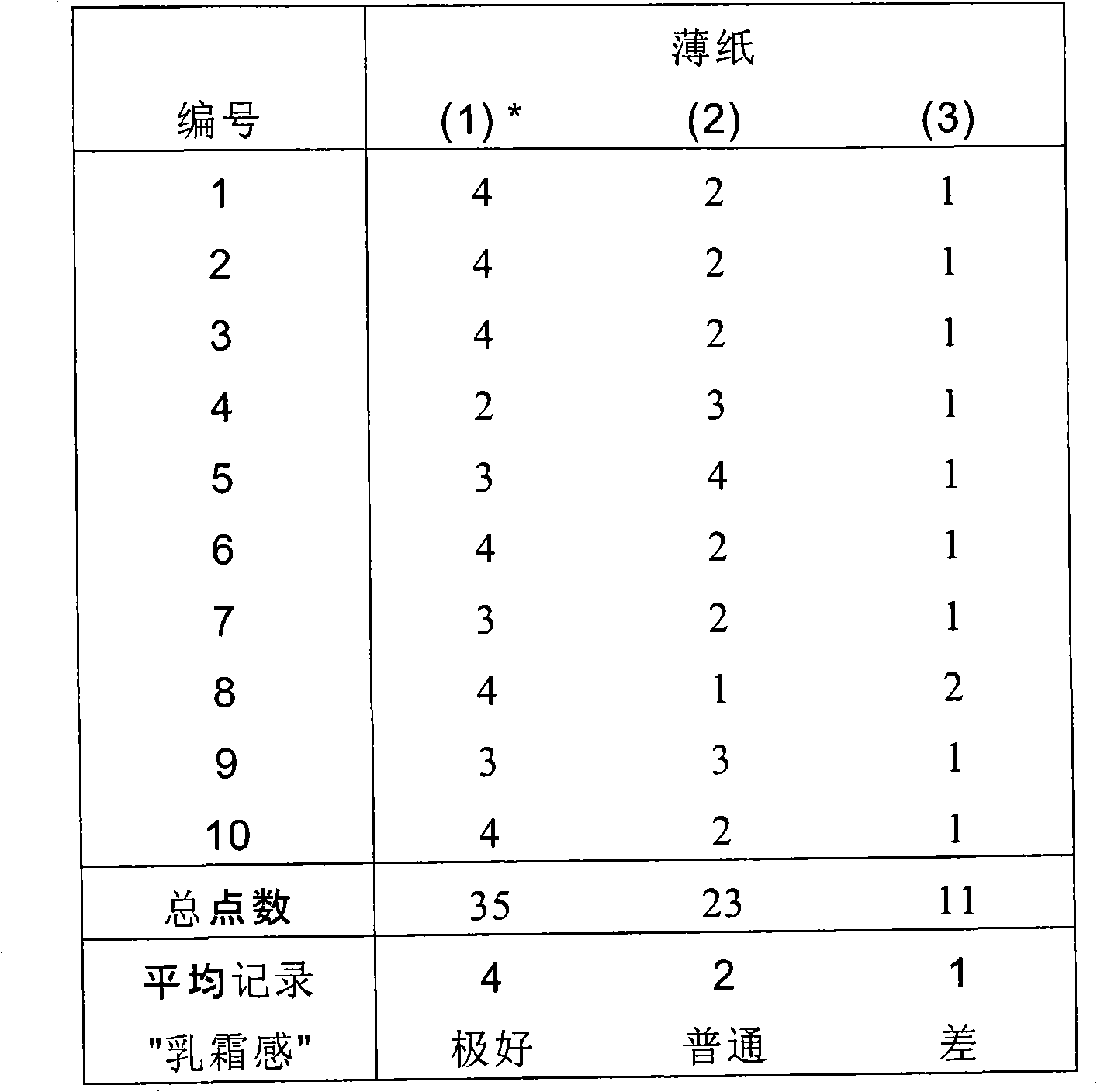

[0161] Table: Hand properties of "cream feel" for tissue papers (1)-(3)

[0162]

[0163] * Equivalent to working example 7.

[0164] Table: Hand properties of "fluffy" for tissue papers (1)-(3)

[0165]

[0166] * Equivalent to working example 7

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com