Water and oil repellent composition

a technology of composition and oil repellent, applied in the direction of film/foil adhesive, ink, textiles and paper, etc., can solve the problems of soft hand of soft fiber products, the demerits resulting from such a polymer have not been fundamentally overcome, and the object coated or treated with such a polymer becomes very hard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0141] In a 300 mL glass beaker, 34.4 g of C6F13C2H4OCOC(CH3)═CH2 (hereinafter referred to as FMA, which forms a homopolymer having no melting point attributable to fine crystals (hereinafter referred to Tm) and a glass transition point (hereinafter referred to as Tg) of 51.5° C.), 1.1 g of polyoxyethylene oleyl ether as an emulsifier (an adduct with about 20 mol of ethylene oxide, hereinafter referred to as PEO-25), 0.3 g of a polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (molecular weight: 3300, polyoxypropylene ratio: 60 mass %, hereinafter referred to as PEPP-33), 0.3 g of stearyltrimethylammonium chloride (hereinafter referred to as STMAC), 48.9 g of ion exchanged water, 13.7 g of dipropylene glycol (hereinafter referred to as DPG) and 0.2 g of normal dodecyl mercaptan (hereinafter referred to as nDSH) were heated for 30 minutes at 50° C. and stirred with a homomixer (Biomixer, manufactured by Nihon Seiki Seisakusho) to give a liquid mixture.

[0142] The resul...

examples 2 to 8

[0143] Polymerization was carried out in the same manner as in Example 1 except that the monomers shown in Table 1 were used in the amounts (unit: g) shown in Table 1 to give emulsions.

TABLE 1Ex. 1Ex. 2Ex. 3Ex. 4Ex. 5Ex. 6Ex. 7Ex. 8FMA(a)34.432.332.332.333.0———FA—————34.432.3—8FA———————32.335DPBI(b)—2.1————2.12.1BOBI(b)——2.1—————BOIPBI(b)———2.1————GMA(b)————1.4———Solid28.630.729.330.328.229.129.627.5content %

[0144] The abbreviations in Table 1 have the following meanings.

[0145] FA: C6F13C2H4OCOCH═CH2 (Tm: not exist Tg: not exist),

[0146] 8FA: C8F17C2H4OCOCH═CH2 (Tm: 75° C., Tg: not exist),

[0147] 35DPBI: 3,5-Dimethylpyrazole adduct of 2-isocyanatoethyl (meth)acrylate,

[0148] BOBI: 2-Butanone oxime adduct of 2-isocyanatoethyl (meth)acrylate and

[0149] GMA: Glycidyl methacrylate.

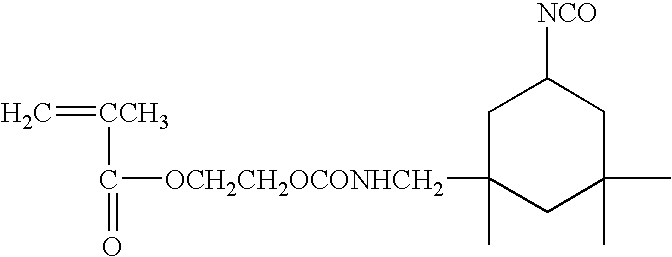

[0150] BOIPBI:

example 9

[0151] Into a 1 L glass beaker, 228.4 g of FMA, 61.8 g of stearyl acrylate (Tm: 42° C., Tg: not exist, hereinafter referred to as StA), 18.5 g of 35 DPBI, 9.6 g of PEO-25, 2.8 g of PEPP-33, 2.8 g of STMAC, 447.5 g of ion exchanged water, 123.6 g of DPG and 2.2 g of nDSH were put, and the same operation as in Example 1 was carried out to obtain a liquid mixture.

[0152] The resulting liquid mixture was processed into an emulsion with a high pressure emulsifier (LAB60-10TBS, manufactured by APV GAULIN K. K.) at 40 MPa, while maintained at 50° C. 697.6 g of the resulting emulsion was placed in a 1 L stainless steel autoclave and cooled to 30° C. or below. 1.4 g of VA061 as a polymerization initiator and 1.0 g of acetic acid were added, and after vapor phase replacement with nitrogen, polymerization was carried out at 55° C. for 12 hours with stirring to give an emulsion having a solid content of 35.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com