Scutcher

A cotton cleaning machine and cotton cleaning technology, applied in the field of cotton cleaning machines, can solve the problems of low production efficiency, high cost and inappropriateness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

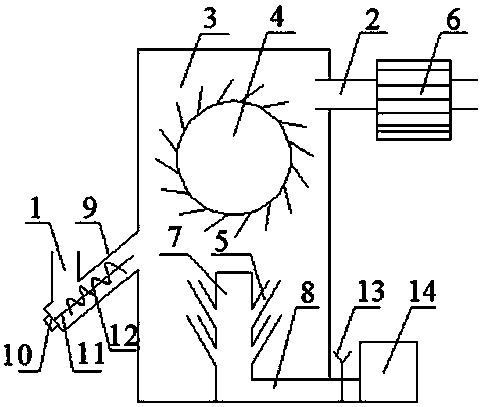

[0014] Such as figure 1 As shown, a kind of cleaning machine of the present invention comprises cleaning bin 3, is located at the cotton inlet 1 on the side wall of cleaning bin 3, is located at beater 4 in cleaning bin 3; Said cleaning bin 3 The inner bottom is provided with a vertical gas channel 7, and the gas channel 7 is externally connected to the gas supply device 14 through a horizontal pipe 8; the gas channel 7 is provided with a gas spray head 5, and the gas spray head 5 is provided with an upward inclination angle.

[0015] Further, the horizontal pipe 8 is provided with an air pressure control valve 13, so that the gas flow in the horizontal pipe 8 can be adjusted. If the gas flow is large, the particle size of the separated impurities will be small, and if the gas flow is small, the particle size of the separated impurities will be small. Big.

[0016] Further, the cotton outlet 2 is located near the top of the cleaning bin 2 .

[0017] Further, the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com