Oscillation beating type impurity removal device

A beater, conveyor belt technology, applied in textiles and papermaking, fiber processing, fiber cleaning machines, etc., can solve the problems of high production cost, difficult to remove, complicated production and process, and reduce design and manufacturing costs, simple structure, The effect of convenient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the present invention is further described:

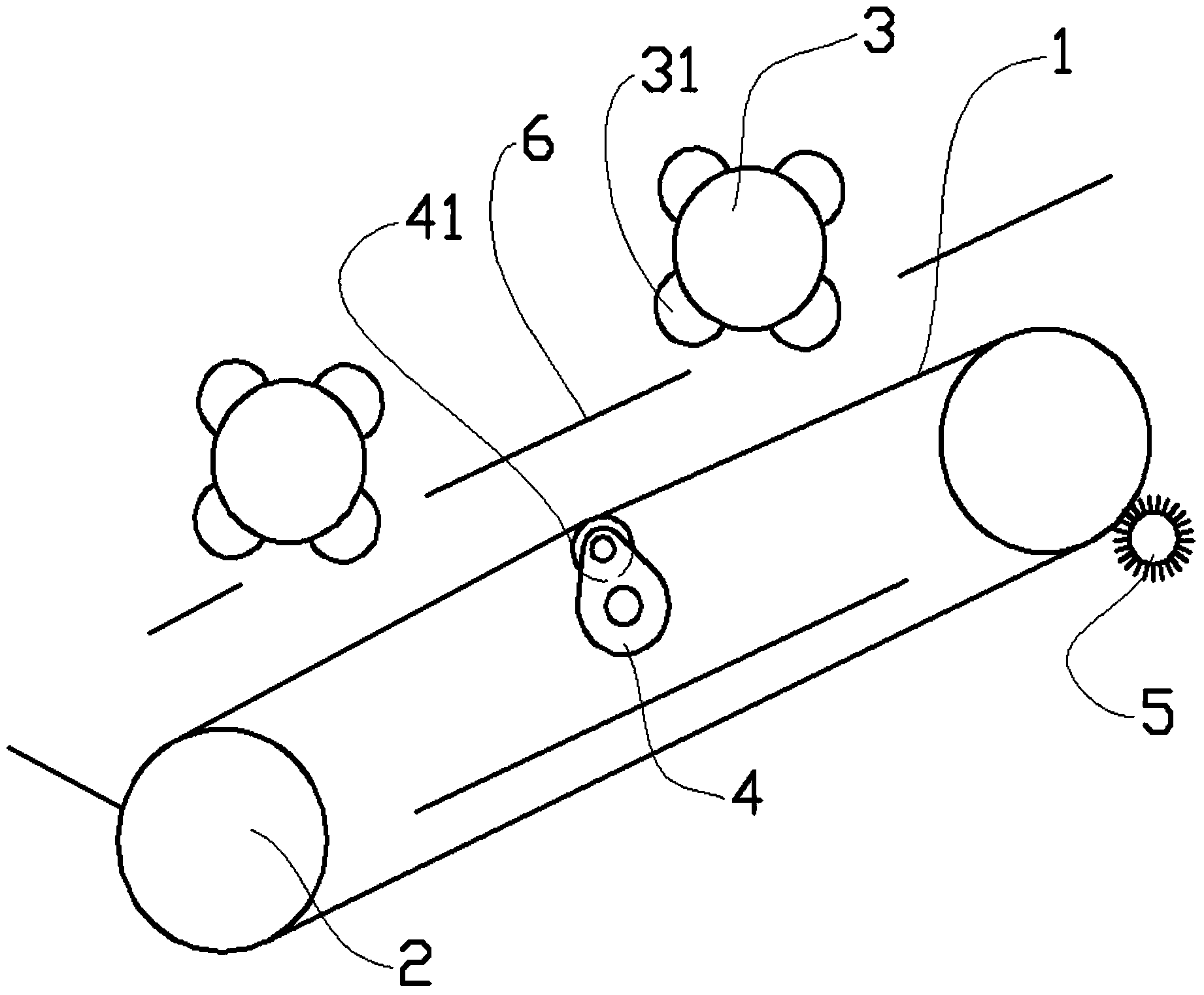

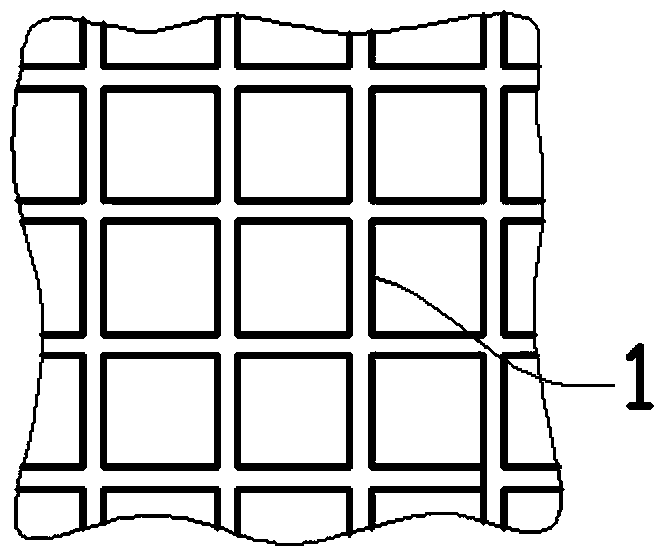

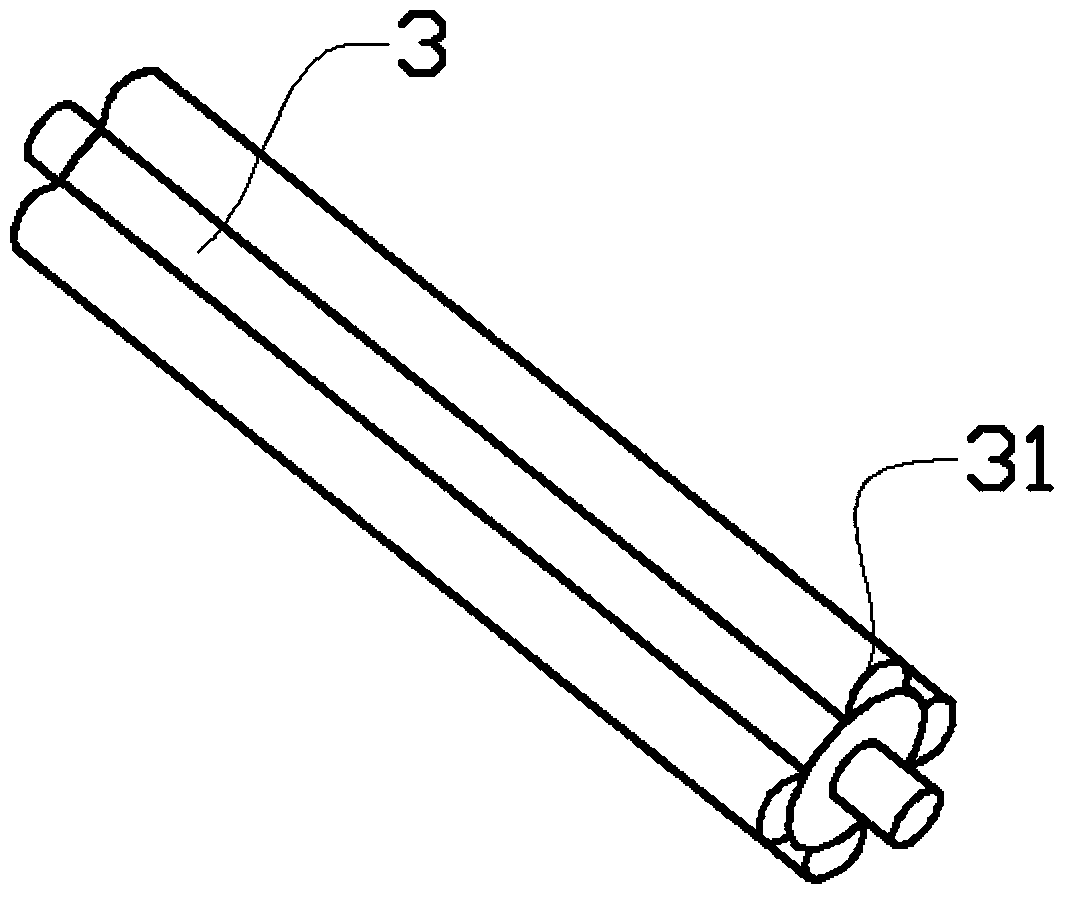

[0013] Such as figure 1 As shown in the embodiment, the vibrating and beating impurity removal device includes a conveyor belt 1, a conveyor roller 2, a convex beating hand 3, and a vibrating roller 4. The conveyor belt 1 is connected end to end, and the surface is netted, such as figure 2 As shown, the conveyor belt 1 is made of elastic material, the conveyor rollers 2 are used in pairs, and are placed horizontally relative to the ground. A low placement, the conveyor belt 1 is installed obliquely; as image 3 As shown, the protruding beater 3 is in the shape of a long stick, assembled on the top of the conveyor belt 1, parallel to the cross section of the conveyor belt 1, and its roller surface is processed with evenly distributed strip-shaped protruding beating strips 31; The oscillating roller 4 is assembled between the upper and lower planes of the conveyor belt 1 , and the oscill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com