Preparation method of wear-resistant reflector marking coating for cement roads

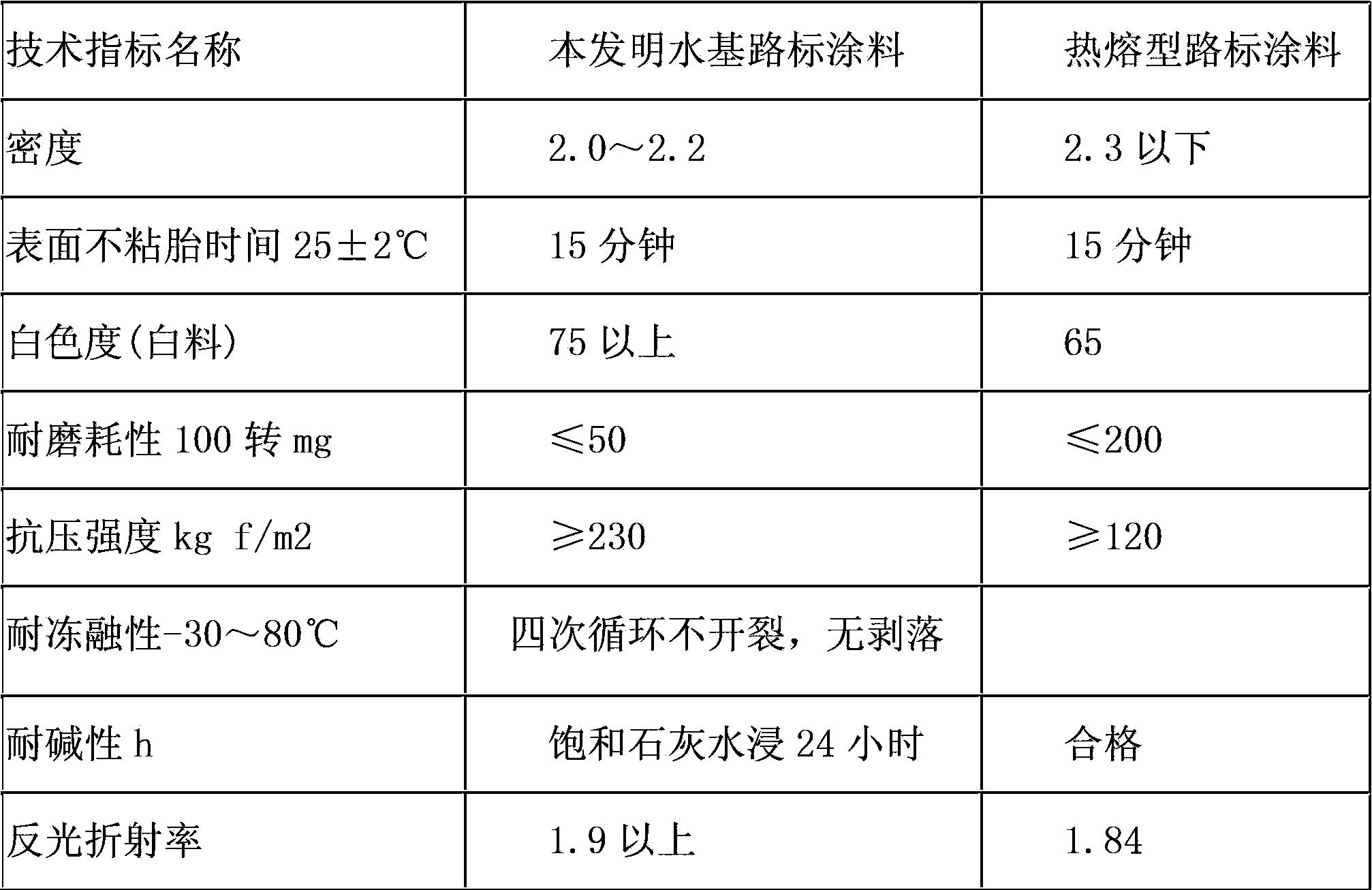

A technology for marking paints and roads, applied to road signs, reflection/signal paints, roads, etc., can solve the problems of high cost and poor wear resistance, and achieve convenient and simple construction, good suspension and high hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a wear-resistant reflective marking paint for cement roads. The paint is composed of the following components in weight percentage: 22% sodium silicate, 5% sodium fluorosilicate, 8% zinc oxide, water-soluble acrylic acid Resin 8%, silane 1.2%, sodium hexametaphosphate 0.7%, polyacrylic acid sodium salt 2%, alcohol ester twelve 7%, rutile titanium dioxide 4%, talcum powder 12%, heavy calcium carbonate 4%, attapulgite 14%, 0.05% simethicone oil, 1% ethylene glycol, 3.5% glass beads, 0.2% carboxymethyl cellulose, and water as the balance, among which the particle size of rutile titanium dioxide and talcum powder is 300-400 mesh, weight The particle size of calcium carbonate is 200~300 orders, and the particle size of attapulgite is 240~320 orders; The preparation method is carried out as follows:

[0026] (1) Weigh the ingredients according to the above percentages;

[0027] (2) Put sodium silicate into the reaction kettle, add water and stir to dil...

Embodiment 2

[0032] A method for preparing a wear-resistant reflective marking paint for cement roads. The paint is composed of the following components in weight percentage: 28% sodium silicate, 3% sodium fluorosilicate, 10% zinc oxide, water-soluble acrylic acid Resin 6%, silane 1.8%, sodium hexametaphosphate 0.2%, polyacrylic acid sodium salt 3%, alcohol ester twelve 1.5%, rutile titanium dioxide 7%, talcum powder 8%, heavy calcium carbonate 6%, attapulgite 12%, 0.1% simethicone oil, 0.6% ethylene glycol, 5.5% glass beads, 0.1% carboxymethyl cellulose, and water as the balance, among which the particle size of rutile titanium dioxide and talcum powder is 300-400 mesh, weight The particle size of calcium carbonate is 200~300 orders, and the particle size of attapulgite is 240~320 orders; The preparation method is carried out as follows:

[0033] (1) Weigh the ingredients according to the above percentages;

[0034] (2) Put sodium silicate into the reaction kettle, add water and stir to ...

Embodiment 3

[0039]A method for preparing a wear-resistant reflective marking paint for cement roads. The paint is composed of the following components in weight percentage: 25% sodium silicate, 4% sodium fluorosilicate, 9% zinc oxide, water-soluble acrylic acid Resin 7%, silane 1.6%, sodium hexametaphosphate 0.5%, polyacrylic acid sodium salt 2.5%, alcohol ester twelve 4%, rutile titanium dioxide 5.5%, talcum powder 10%, heavy calcium carbonate 5%, attapulgite 13%, 0.07% dimethyl silicone oil, 0.8% ethylene glycol, 4.5% glass microspheres, 0.15% carboxymethyl cellulose, and water as the balance, among which the particle size of rutile titanium dioxide and talcum powder is 300-400 mesh, weight The particle size of calcium carbonate is 200~300 orders, and the particle size of attapulgite is 240~320 orders; The preparation method is carried out as follows:

[0040] (1) Weigh the ingredients according to the above percentages;

[0041] (2) Put sodium silicate into the reaction kettle, add wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com