Efficient loosening and cotton opening knocking device

A loose and high-efficiency technology, used in fiber cleaning, fiber cleaning machines, textiles and papermaking, etc., can solve problems such as increasing the difficulty of opening, and achieve the effect of enhancing the opening effect, saving electricity, and having a good opening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

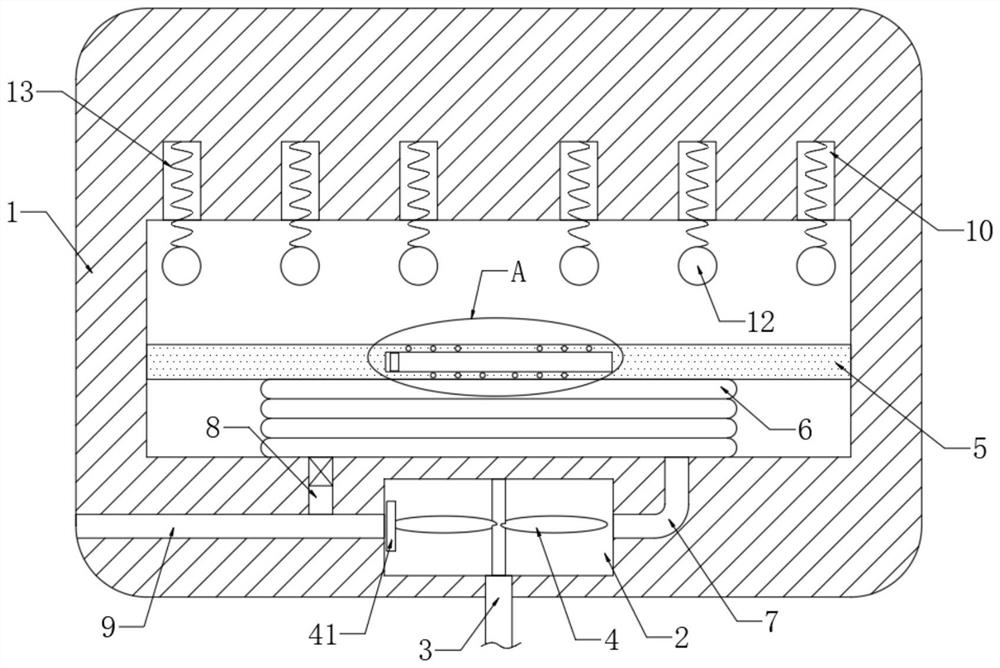

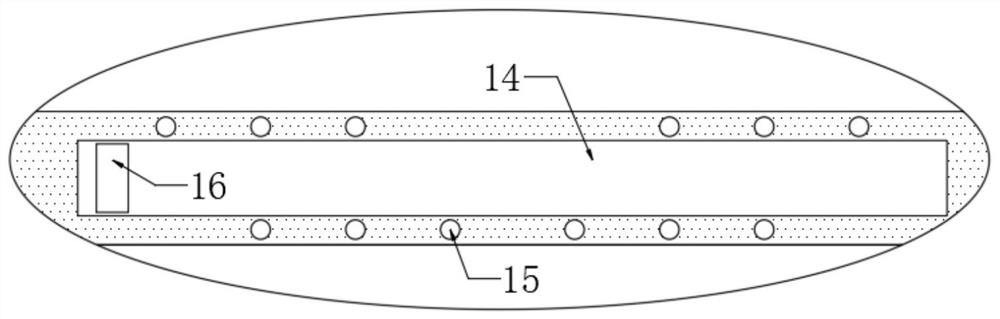

[0020] refer to Figure 1-2 , a high-efficiency loosening and knocking device, comprising a processing box 1, a drive groove 2 is provided on the side wall of the processing box 1, an air intake pipe 3 is arranged at the inner bottom of the drive groove 2, and a wind wheel 4 is rotatably connected in the drive groove 2 One of the blades of the wind wheel 4 is fixedly connected with a sealing sheet 41. It should be noted that the driving groove 2 is a circular groove, and the side wall of the sealing sheet 41 is in close contact with the inner wall of the driving groove 2, and there is a good Air tightness. A support plate 5 is slidably connected in the processing box 1, and a telescopic air bag 6 is fixedly connected between the lower end of the support plate 5 and the inner bottom of the processing box 1. There is an exhaust groove 9 on the inner wall of the air bag, and the exhaust groove 9 is communicated with the telescopic air bag 6 through the one-way air outlet pipe 8....

Embodiment 2

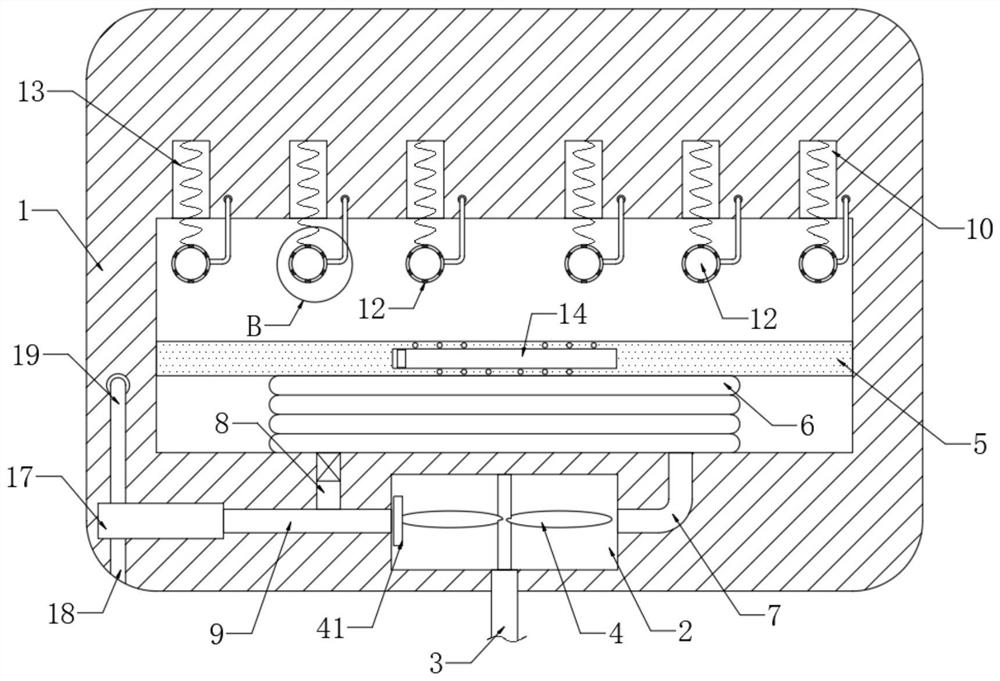

[0026] refer to Figure 3-4 , and the difference from the first embodiment is that the processing box 1 is provided with a vortex tube 17 communicating with the exhaust groove 9, and the vortex tube 17 is installed with a hot gas pipe 19 and a cold gas pipe 18, which are communicated with the inside thereof, the vortex pipe 17, the hot gas pipe The installation and connection methods of 19 and the cold air pipe 18 belong to the existing mature technology, and will not be described in detail. The knocking ball 12 is hollow and made of rubber material. The knocking ball 12 communicates with the hot air pipe 19 through the shunt pipe 11. The side wall of the knocking ball 12 is provided with a plurality of exhaust holes 121. The exhaust holes 121 Distributed at equal intervals along the periphery of the knocking ball 12 , and a pressure relief valve is installed in the exhaust hole 121 .

[0027] In this embodiment, the compressed air discharged along the exhaust groove 9 will e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com