Foam pad and production method thereof

A technology of foam pad and base layer, which is applied in the high security field and can solve the problems such as the need to be further improved in sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A foam pad, the foam pad includes a base layer and a film layer covering the upper surface and the lower surface of the base layer, the base layer is a foam, and is a uniform pore-like body, the average diameter of the pores is is 1-30 μm; the film layer is a coating layer, and the film layer is uniform and dense; the thickness of the base layer is 0.5mm; the thickness of the film layer is 0.02mm;

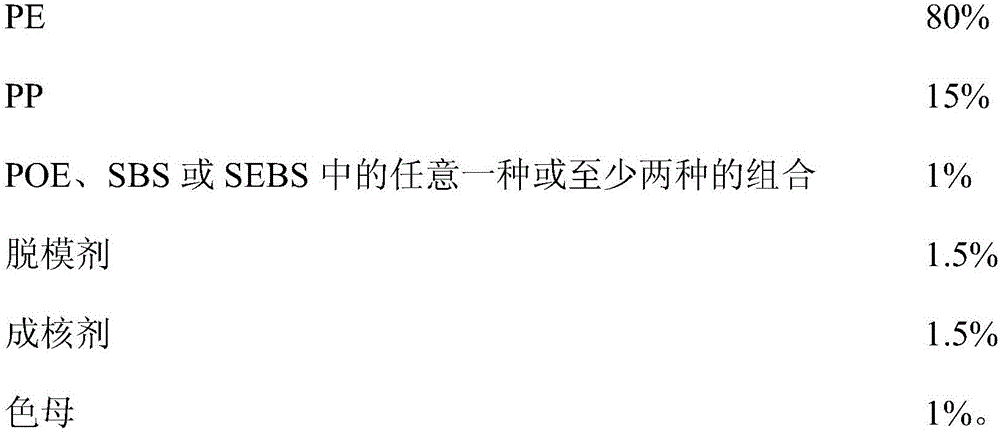

[0070] The base layer is mainly prepared from the following raw materials in terms of mass percentage:

[0071]

[0072] The release agent is selected from oleic acid amide;

[0073] The nucleating agent is selected from masterbatches with sodium bicarbonate and citric acid as the main active ingredients and PE, PP or EVA as the carrier.

[0074] The film layer is mainly prepared from the following raw materials according to the mass percentage:

[0075]

[0076] The tackifier is selected from EEA (ethylene ethyl acrylate).

[0077] The release agent is selected fro...

Embodiment 2

[0083] A foam pad, the foam pad includes a base layer and a film layer covering the upper surface and the lower surface of the base layer, the base layer is a foam, and is a uniform pore-like body, the average diameter of the pores is 50-100 μm; the film layer is a coating layer, and the film layer is uniform and dense; the thickness of the base layer is 10.0mm; the thickness of the film layer is 0.15mm;

[0084] The base layer is mainly prepared from the following raw materials in terms of mass percentage:

[0085]

[0086] The release agent is selected from oleamide and erucamide.

[0087] Preferably, the nucleating agent is selected from masterbatches with sodium bicarbonate and citric acid as the main active ingredients and PE, PP or EVA as the carrier.

[0088] The film layer is mainly prepared from the following raw materials according to the mass percentage:

[0089]

[0090]

[0091] The tackifier is selected from EEA and polyester.

[0092] The mold releas...

Embodiment 3

[0098] A foam pad, the foam pad includes a base layer and a film layer covering the upper surface and the lower surface of the base layer, the base layer is a foam, and is a uniform pore-like body, the average diameter of the pores is 30-80 μm; the film layer is a coating layer, and the film layer is uniform and dense; the thickness of the base layer is 5.0mm; the thickness of the film layer is 0.10mm;

[0099] The base layer is mainly prepared from the following raw materials in terms of mass percentage:

[0100]

[0101]

[0102] The release agent is selected from erucamide.

[0103] Preferably, the nucleating agent is selected from masterbatches with sodium bicarbonate and citric acid as the main active ingredients and PE, PP or EVA as the carrier.

[0104] The film layer is mainly prepared from the following raw materials according to the mass percentage:

[0105]

[0106] The tackifier is selected from maleic anhydride grafted resins.

[0107] The mold release...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com