Bottle cap inner spacer material suitable for carbonated beverage

A technology of carbonated beverages and inner gaskets, which is applied in the field of carbonated beverage bottle cap inner gaskets. It can solve the problems that the sealing performance and opening performance cannot be balanced, and the performance needs to be further improved, so as to achieve good bottle cap opening performance and good retention. The effect of air performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

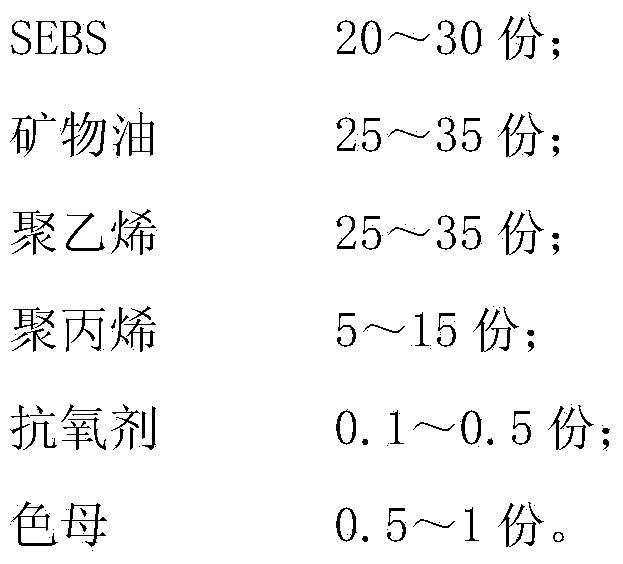

[0012] For the TPE product provided in this example, SEBS, mineral oil, polyethylene, polypropylene, antioxidant, color masterbatch and other ingredients are put into a high-speed mixer for blending according to the following composition formula:

[0013]

[0014] The blended material is then added into a twin-screw extruder for mixing and granulation to form a cushioning material for bottle caps suitable for carbonated beverages. The properties of the obtained product are shown in Table 1 below.

[0015] Table 1: Product performance test table of TPE inner padding for dairy products

[0016] Test items

Embodiment 2

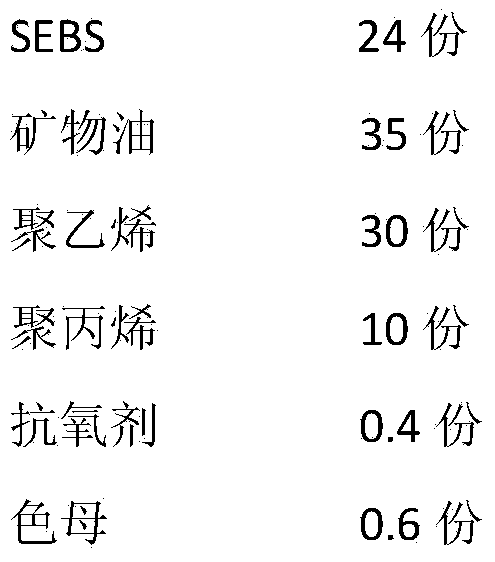

[0018] The cushion material composition in the bottle cap suitable for carbonated beverages of this embodiment,

[0019]

[0020]

[0021] Wherein, the SEBS is a linear three-block copolymer with polystyrene as the terminal block and ethylene-butene copolymer obtained by hydrogenation of polybutadiene as the middle elastic block.

Embodiment 3

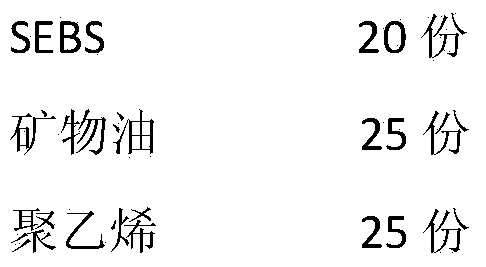

[0023] The cushion material composition in the bottle cap suitable for carbonated beverages of this embodiment,

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com