Drying device for cloth processing

A drying device and cloth technology, which is applied in the treatment of textile materials, elongation of fabrics, mechanical cleaning, etc., can solve the problems of inability to remove wrinkles, increase equipment costs and production processes, and achieve improved opening effect and good buffering. Effect, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

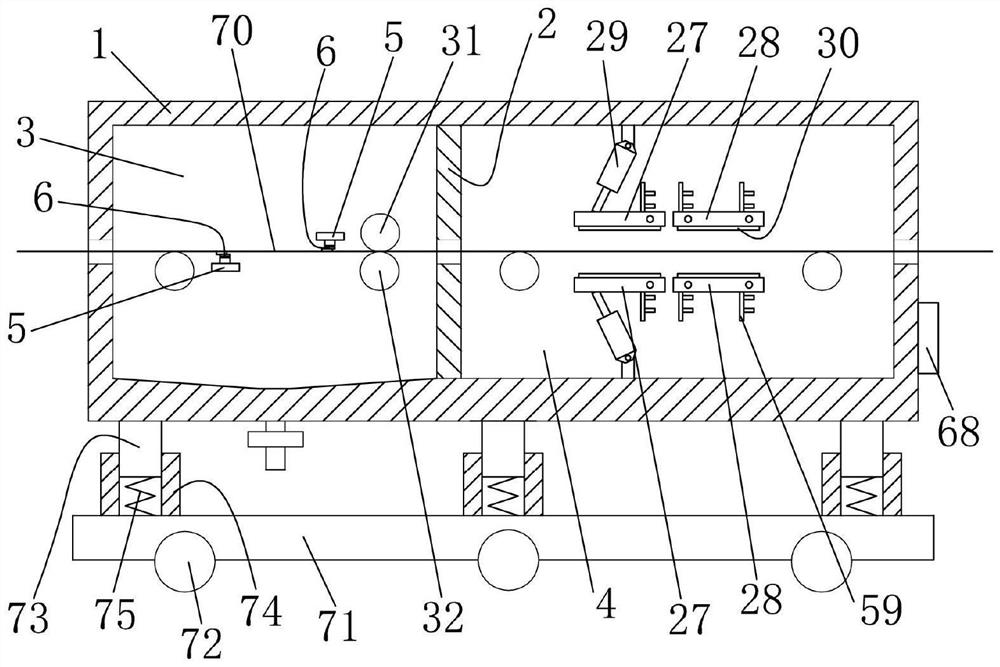

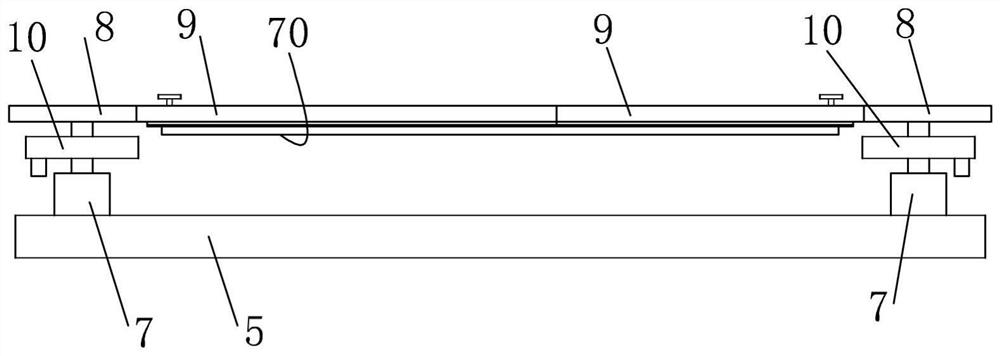

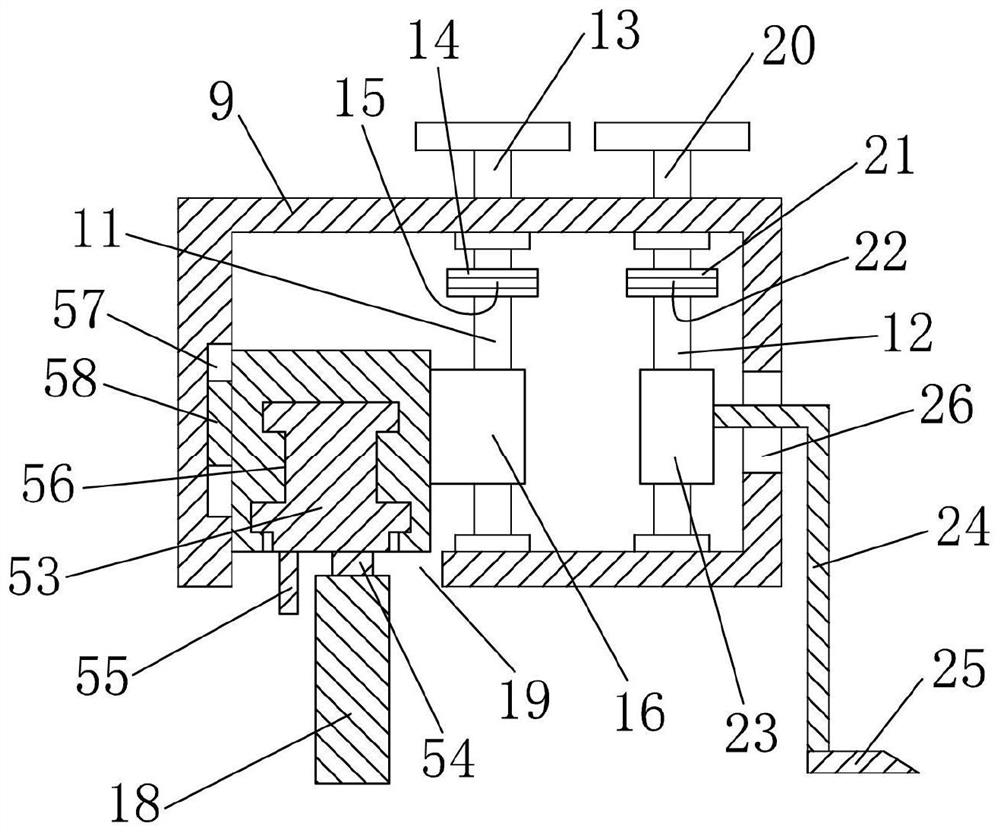

[0028] Embodiment: a kind of drying device for cloth processing, such as Figure 1-Figure 11 As shown, it includes a box body 1 and a base 71, the base 71 is provided with a roller 72 for a convenient handling device, the roller 72 is a self-locking roller, the box 1 is located above the base 71, and the box body The bottom end of 1 is provided with support column 73, and the bottom sliding sleeve of described support column 73 is provided with spring sleeve 74, and the bottom end of described spring sleeve 74 is fixedly connected with the top end of base 71, and the inside of described spring sleeve 74 A spring 75 is provided, one end of the spring 75 is connected to the bottom end of the support column 73 , and the other end of the spring 75 is connected to the top end of the base 71 . The support column, the spring sleeve, the spring and the base cooperate with each other, so that the device has a good buffer effect during the transportation process and is convenient for tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com