Impurity removing device special for separating calotropis gigantean fiber capsule seeds

A technology of horn gourd fibers and fibers, which is applied in the field of textile machinery, can solve the problems of destroying the unique properties of fibers, easy damage, and increased labor costs, and achieve the effects of small physical impact, improved production efficiency, and effective impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

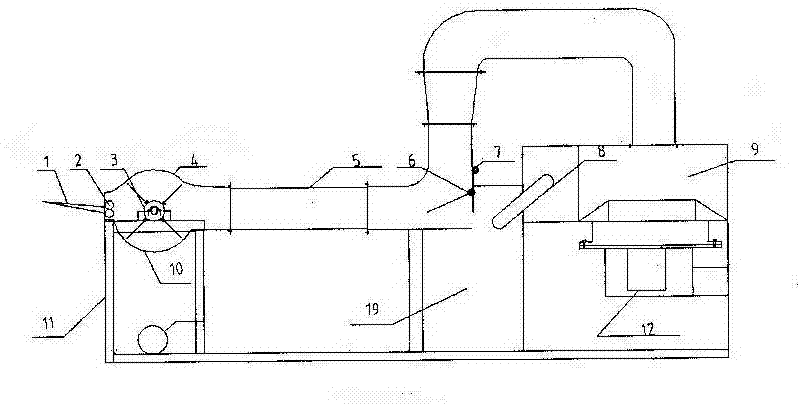

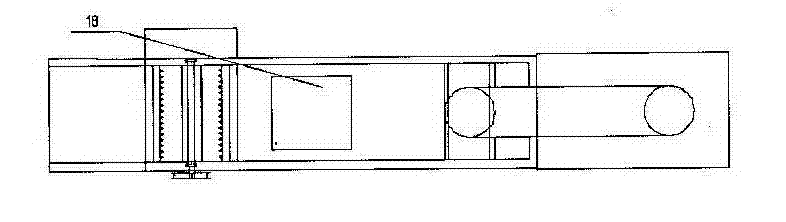

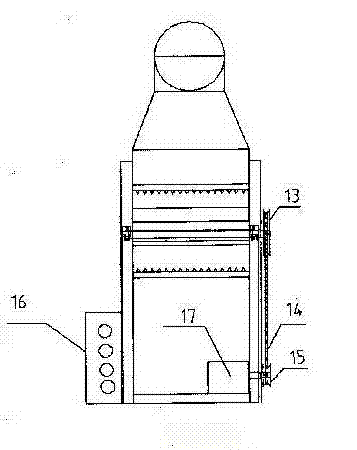

[0018] With reference to accompanying drawing: be provided with hood 4 at the front end upper part of frame 11, be fixed with the feeding device that is made up of feeding board 1, feeding roller 2, dust bar 10 and four-wing beater 3 on the frame in the hood, The lower part of the front end of the frame 11 is fixed with a transmission system composed of a main motor 17 and an electric control device, wherein the main motor belt pulley 15 is connected to the four-wing beater belt pulley 13 through a triangle belt 14; the electric control device is composed of an electric control box 16 and its It is composed of a frequency converter and an electrical switch; in the middle of the frame 11, a cotton delivery pipe 5 is provided, and a cotton delivery pipe window 18 for observation is provided on the surface of the cotton delivery pipe, and an upper adjustment plate 7 is arranged inside the cotton delivery pipe. , the lower adjustment plate 6 and the negative pressure air duct 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com