Cotton basket coiler

A technology of a rolling machine and a cotton box, applied in the field of textile machinery, can solve the problems of easy layering, cumbersome adjustment, long equipment flow, etc., and achieve the effects of improving lateral uniformity, overcoming complex structure, and reasonable and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

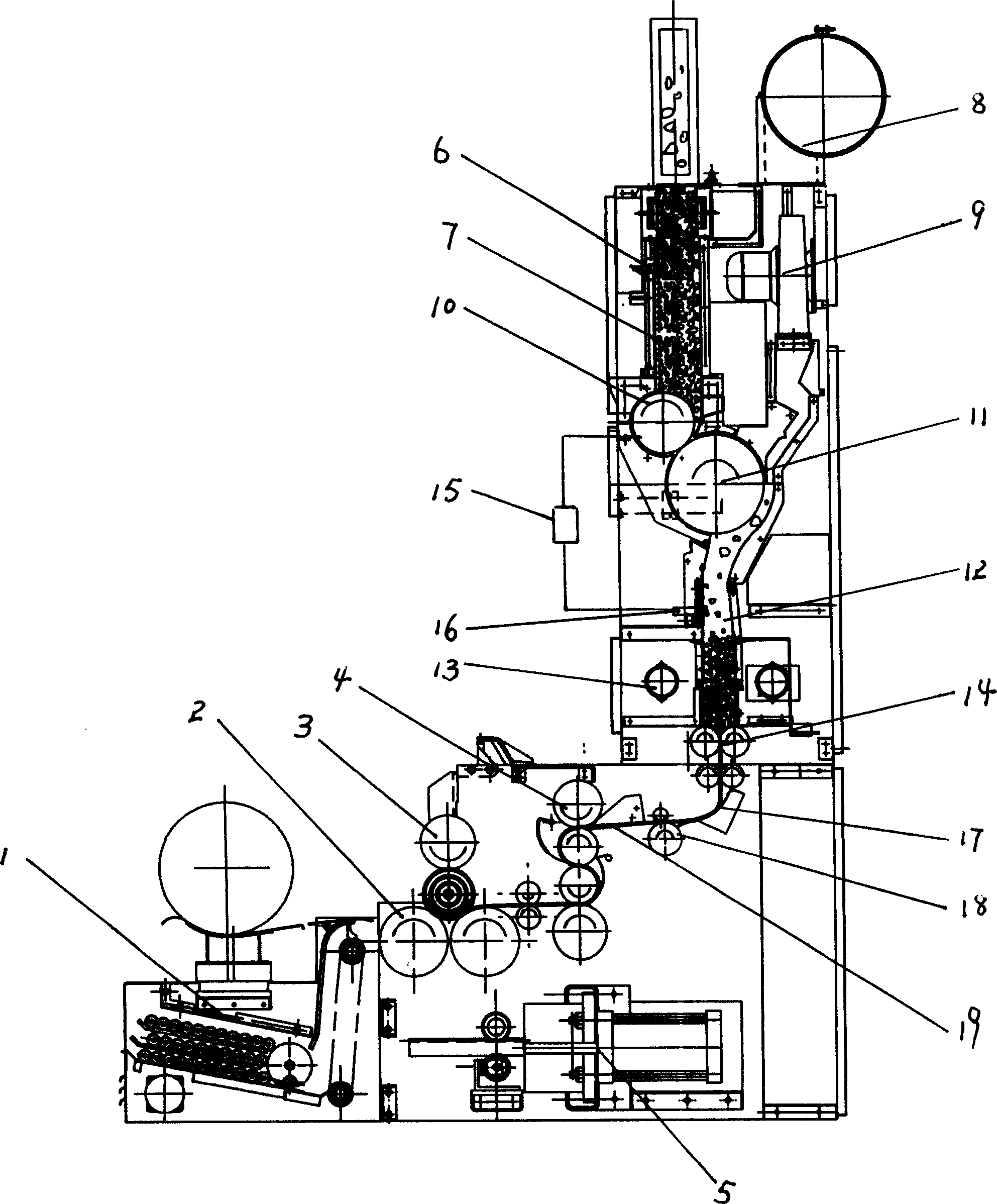

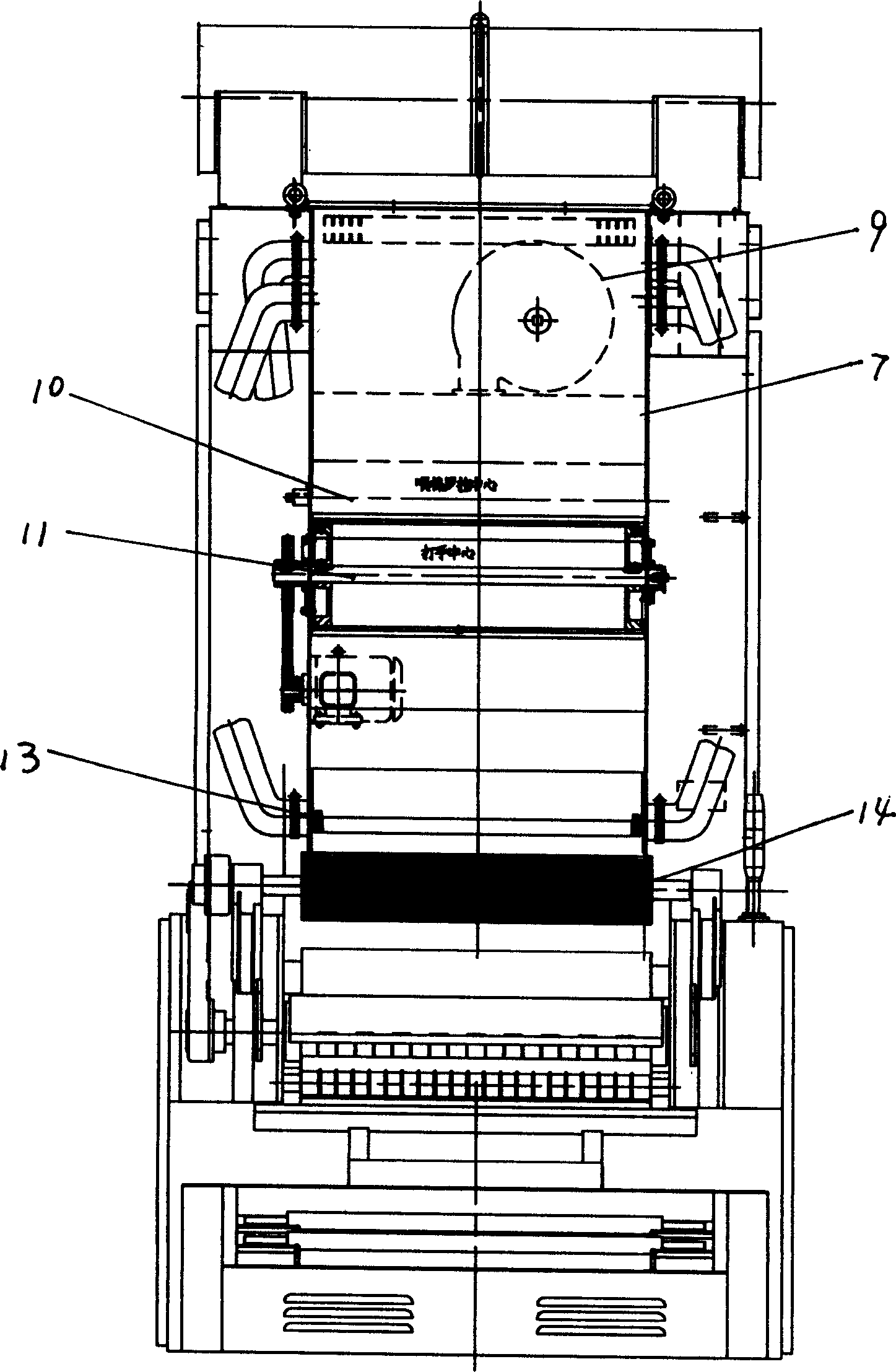

[0015] The present invention is further described below in conjunction with accompanying drawing:

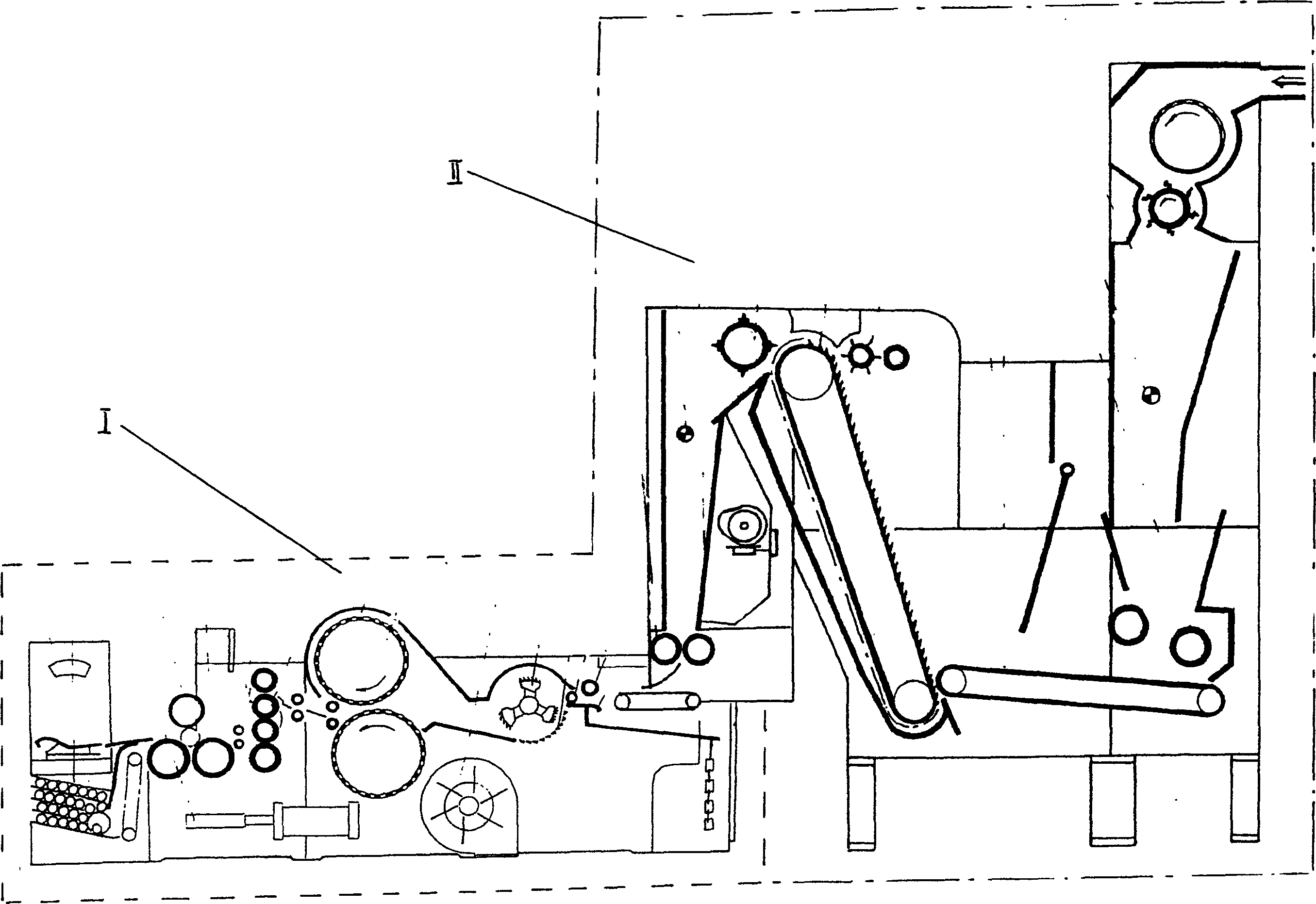

[0016] Such as figure 2 , 3 Shown: This cotton box lapping machine consists of lap trolley (1), lap roller (2), press roller (3), compact roller (4) (composed of four rollers arranged vertically) and pneumatic A roll-forming mechanism composed of a pressurizing device (5), wherein: a cotton box is arranged at the rear of the rolling mechanism, and the cotton box is a vertical structure, which successively includes a wind-exhausting and dust-removing device (6) from top to bottom. The upper cotton box (7), the dust exhaust pipe (8) and the circulation fan (9) arranged on one side of the upper cotton box, the cotton feeding roller (10), the opening beater (11), the lower cotton box (12), set The static pressure diffusion box (13) on the corresponding two sides of the lower cotton box and the closed-circuit circulating airflow system formed by the circulating fan (9) and the cot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com