Cotton carding scattering device for home textiles and cotton carding process applying the scattering device

A carding and crafting technology, which is applied in continuous processing, textile and papermaking, combined opening and blowing machines, etc. It can solve the problems that granular impurities cannot be absorbed by wind and affect the purity of spinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

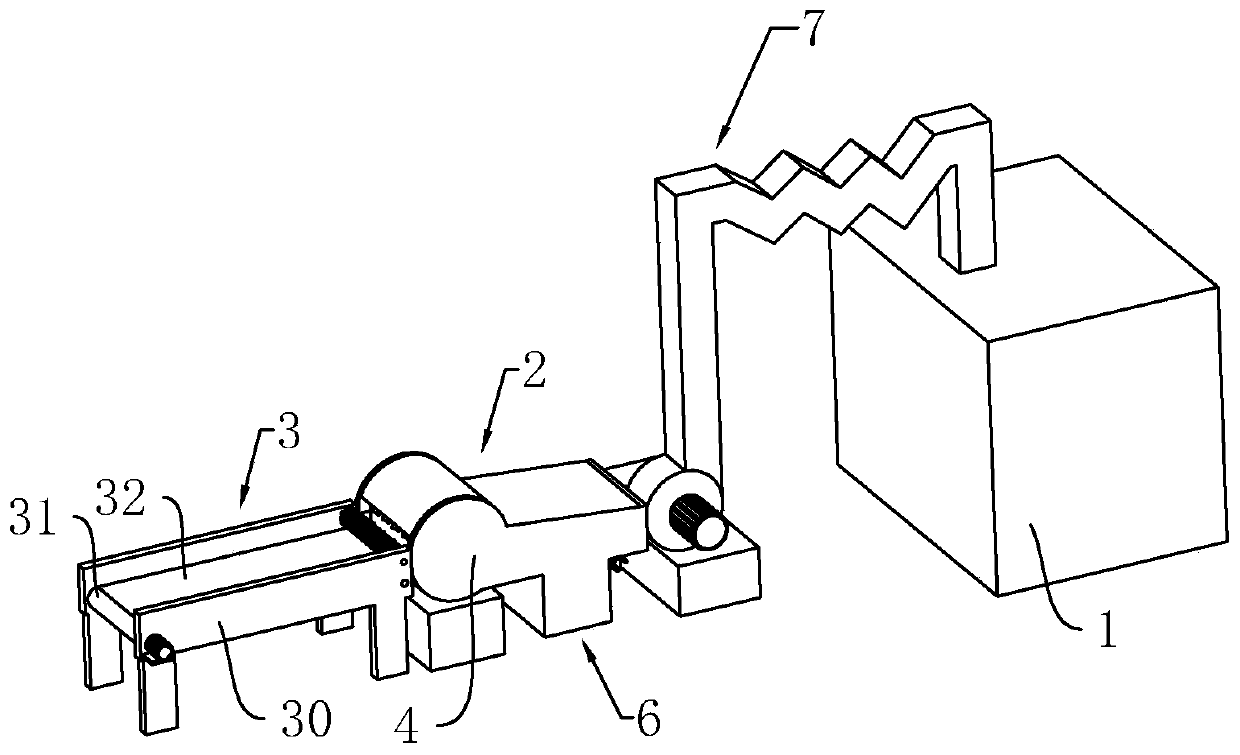

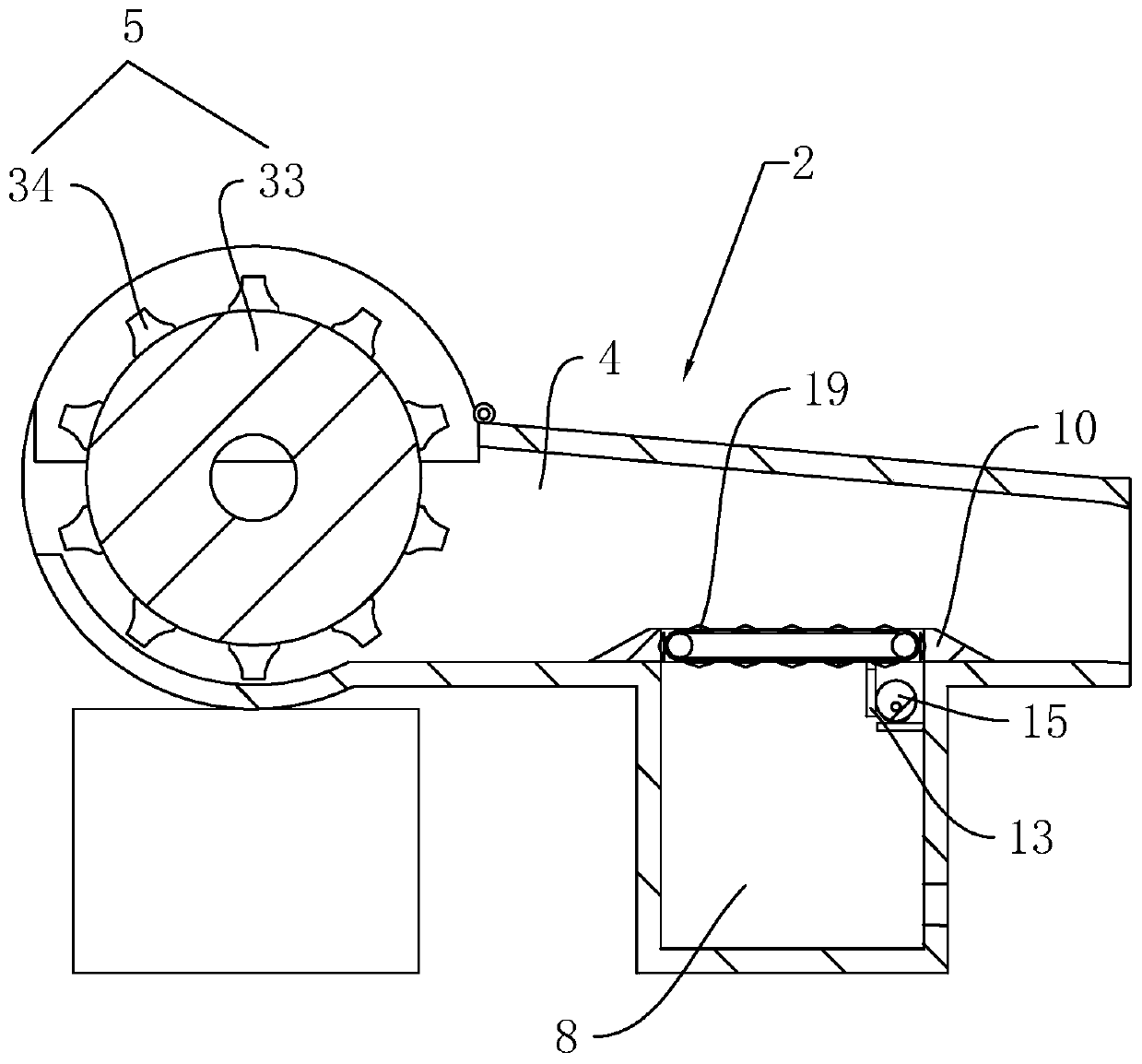

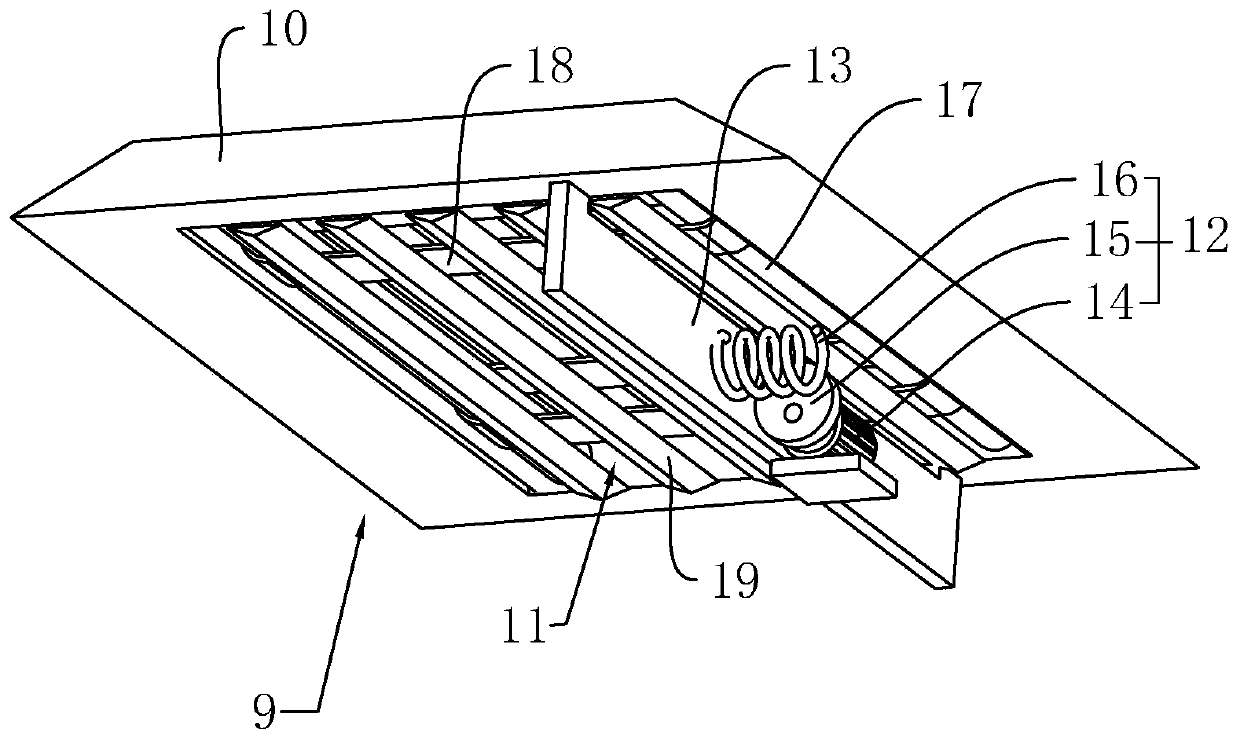

[0043] refer to figure 1 and figure 2 , is a carding and breaking up device 2 for home textile disclosed by the present invention, comprising a cotton storage box 1 and a breaking up device 2 connected to the front end of the cotton storage box 1, wherein the breaking up device 2 includes a feeding mechanism 3, connected to the feeding The cotton opening box 4 of the material mechanism 3, the cotton opening mechanism 5 arranged in the cotton opening box 4, the impurity removal mechanism 6 connected to the cotton opening mechanism 5, the impurity removal mechanism 6 is connected with a fiber for sending fibers to the cotton storage box 1 The feeding mechanism 7 and the impurity removal mechanism 6 include an impurity removal box 8 that is connected to the bottom surface of the opening box 4 and has an upper end opening, and a vibrating screen assembly 9 is arranged at the top opening of the impurity removal box 8 . The fiber raw material is first put into the feeding mechanis...

Embodiment 2

[0054] A carding process, comprising the following steps, step S1, the fibers are broken up, and the agglomerated fibers are preliminarily broken up by a breaking device 2; step S2, the fibers after the preliminary breakup are removed by the impurity removal mechanism 6; step S3, transporting the preliminarily dispersed fibers to the cotton storage box 1 through the blower 20; step S4, sending the fibers to the carding machine for carding after being temporarily stored in the cotton storage box 1. First, pour the fiber clusters into the feed belt 32 and transfer them to the opening box 4 by the feed belt 32, and the fibers in the clusters are initially broken up by the cotton opening mechanism 5. At this time, the fiber clusters are in a loose state, and then the vibrating sieve plate 10 Vibrate and remove impurities from the fiber cluster, so that the particulate impurities in the fiber cluster fall down into the trash removal box 8 under the action of its own gravity, and und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com