An automatic feeding device for a cafeteria

A restaurant and automatic technology, applied in the field of automatic food feeding device and automatic food feeding device in cafeteria, can solve the problems of reducing the dining experience of guests, achieve the effect of preventing rust from polluting dishes, ingenious design, and improving dining experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

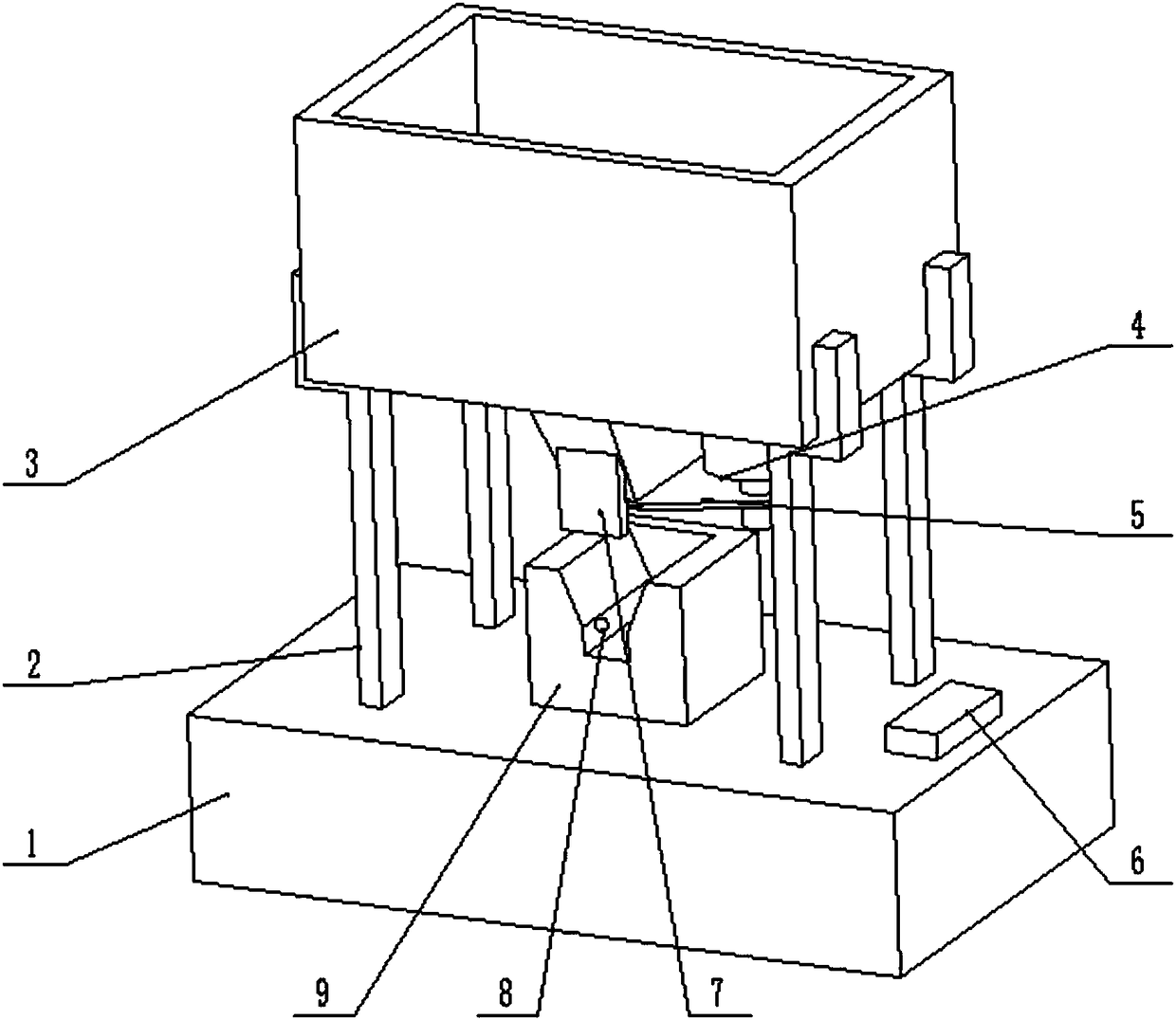

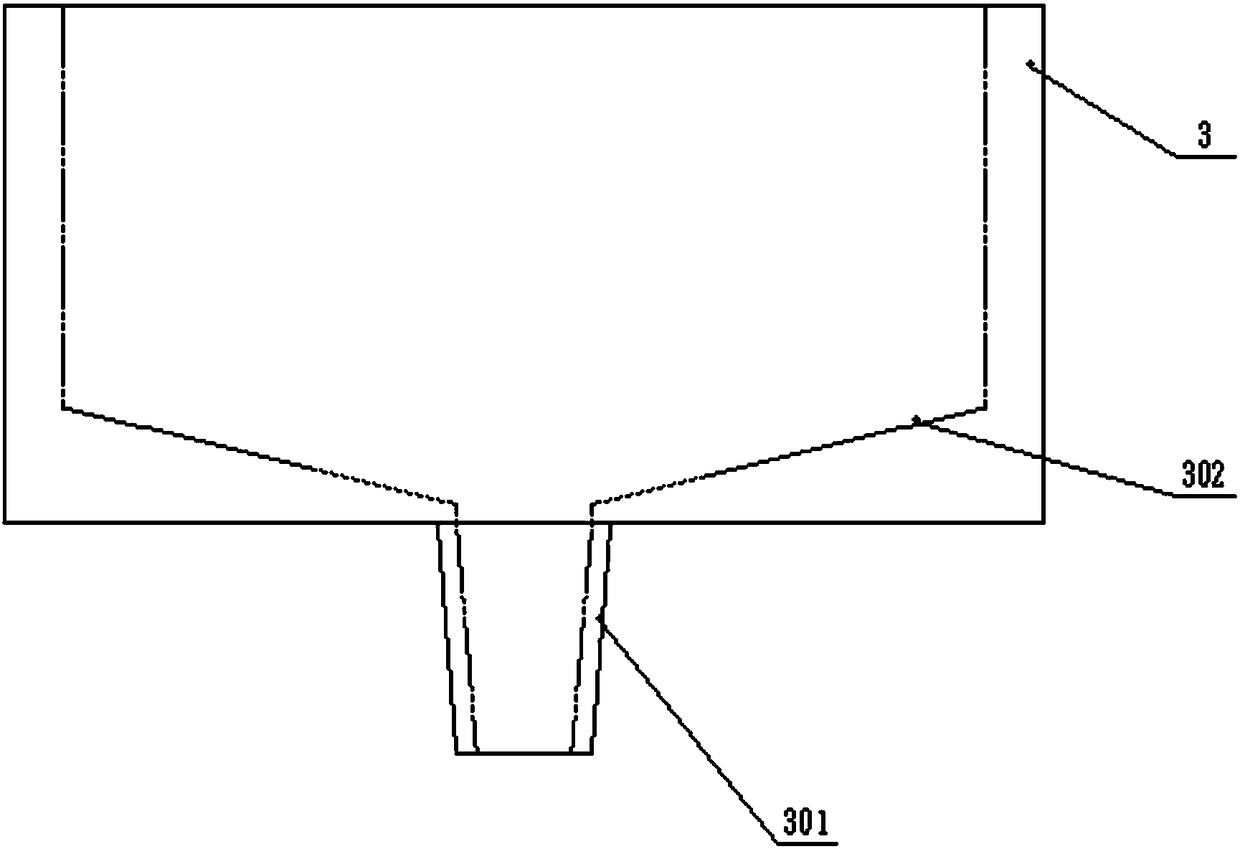

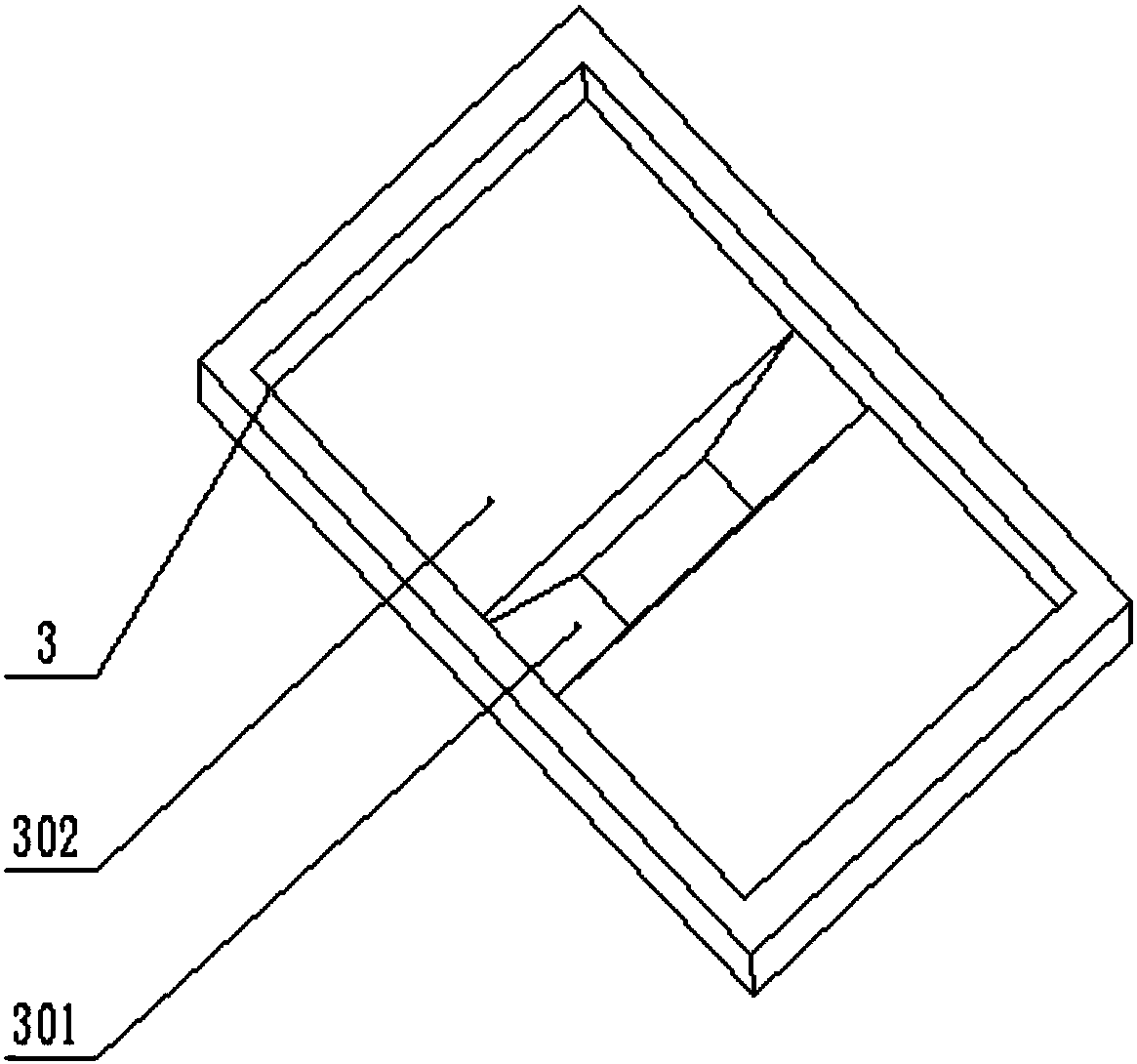

[0014] An automatic food feeding device for a cafeteria, which is composed of a base 1, a support frame 2, a vegetable bin 3, a stepping motor 4, a blocking cutter 5, a controller 6, an iron stopper 7, a sensor 8 and a dining table 9 , there are four support frames 2, which are fixed on the upper surface of the base 1 by bolts, and the vegetable compartment 3 is fixed on the support frame 2 by bolts, and the vegetable compartment 3 is made of stainless steel. The feed motor 4 is fixed on the lower surface of the vegetable bin 3 by bolts, the plugging cutter 5 is installed on the stepper motor 4, and the plugging cutter 5 is made of stainless steel, and the controller 6 is installed On the upper surface of the base 1, the dining table 9 is fixed on the upper surface of the base 1 by bolts, and the dining table 9 is made of non-toxic and environmentally friendly plastic, and the sensor 8 is installed on the dining table 9 , the vegetable bin 3 has an inclined bin bottom 302 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com