Improved airflow type lint cleaning machine

A kind of lint cleaning and air-flow technology, which is applied in the direction of opening and cleaning machines, fiber opening and cleaning machines, etc., can solve the problems of lint damage, poor trash removal effect, blockage, etc., and achieve high work efficiency, simple structure and good trash removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

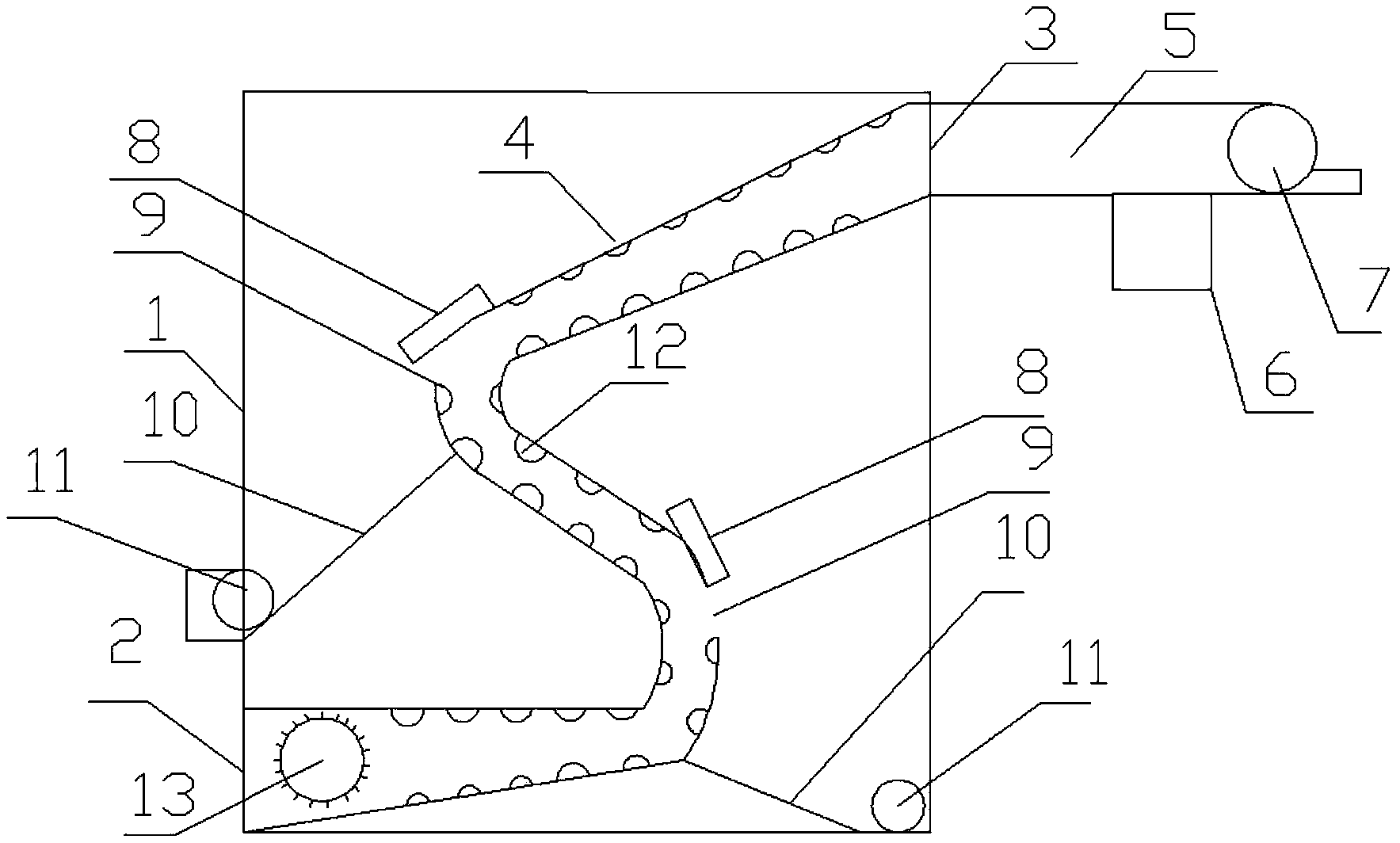

[0014] to combine figure 1 As shown, an improved airflow type lint cleaning machine includes a shell 1, a lint inlet 2 and a lint outlet 3 are arranged on the shell 1, a lint road 4 is provided between the lint inlet 2 and the lint outlet 3, and a lint road 4 At least one sharp bend is provided, and the sharp bend is provided with a miscellaneous discharge notch 9 and a lint support plate 8, and the lower end of the miscellaneous discharge notch 9 is provided with a miscellaneous plate 10 and a miscellaneous discharge auger 11; The roller 13, the lint outlet 3 are connected to the air pipe 5, and the air pipe 5 is connected to the fan 7 and the unloading device 6.

[0015] In this embodiment, hemispherical protrusions 12 are evenly distributed in the lint track 4 . The hemispherical protrusion 12 makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com