Fine scutching machine

A cotton cleaning machine and cotton cleaning technology, which is applied in the direction of opening and cleaning combined machines and cleaning with toothed tools, can solve the problems of wasting manpower and material resources, entanglement on needle punching, and reduced work efficiency, so as to achieve easy cleaning and occupying less space. The small area reduces the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

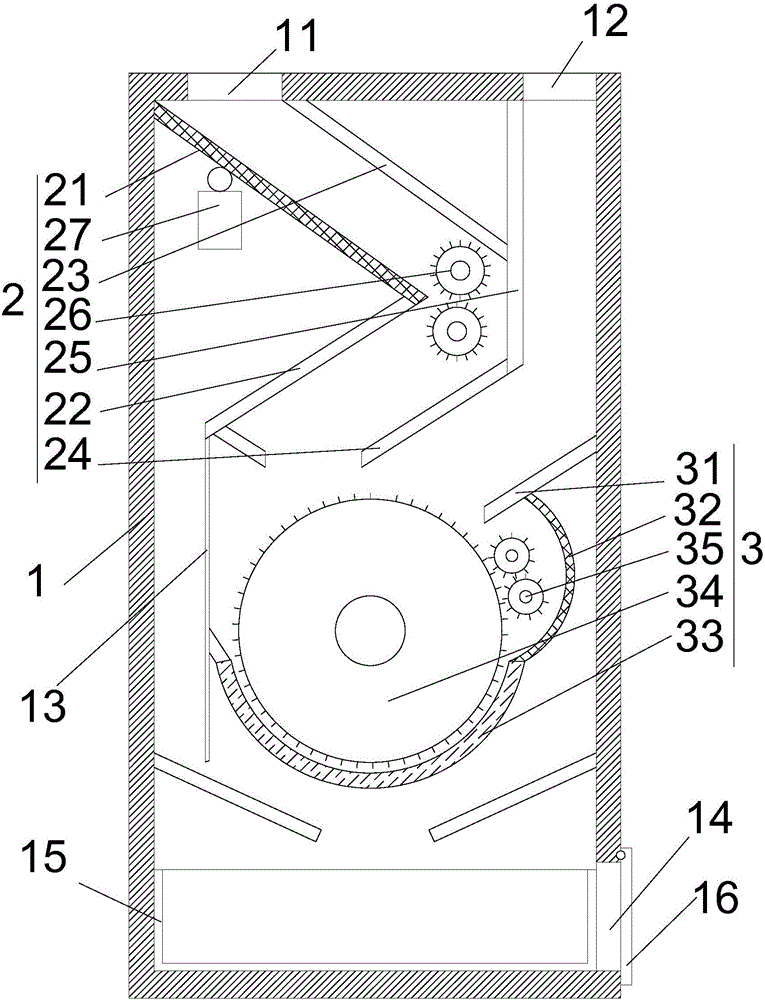

[0019] refer to figure 1 As shown, a kind of fine cotton cleaning machine that the present invention proposes, comprises cleaning box 1, the first dismantling and cleaning mechanism 2 and the second dismantling and cleaning mechanism 3;

[0020] The upper opposite sides of the cleaning box 1 are respectively provided with a feed port 11 and a discharge port 12,

[0021] The first dismantling mechanism 2 comprises a first filter screen 21, a first dividing plate 22, a second dividing plate 23, a third dividing plate 24, a fourth dividing plate 25, a plurality of first small beating rollers 26 and a vibrating motor 27; The first filter screen 21 is installed in the cleaning box 1 and is inclined to the feed port 11 side, and the first dividing plate 22 is installed obliquely in the cleaning box 1 and is positioned at the first filter net 21 below, the first dividing plate 22 and The inclination direction of the first filter screen 21 is opposite, and the second dividing plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com