Aggregate unit for bundle fiber and feeding bundle fiber into carding machine

A combined device and carding machine technology, applied in fiber feeding, fiber processing, deburring devices, etc., can solve problems such as yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

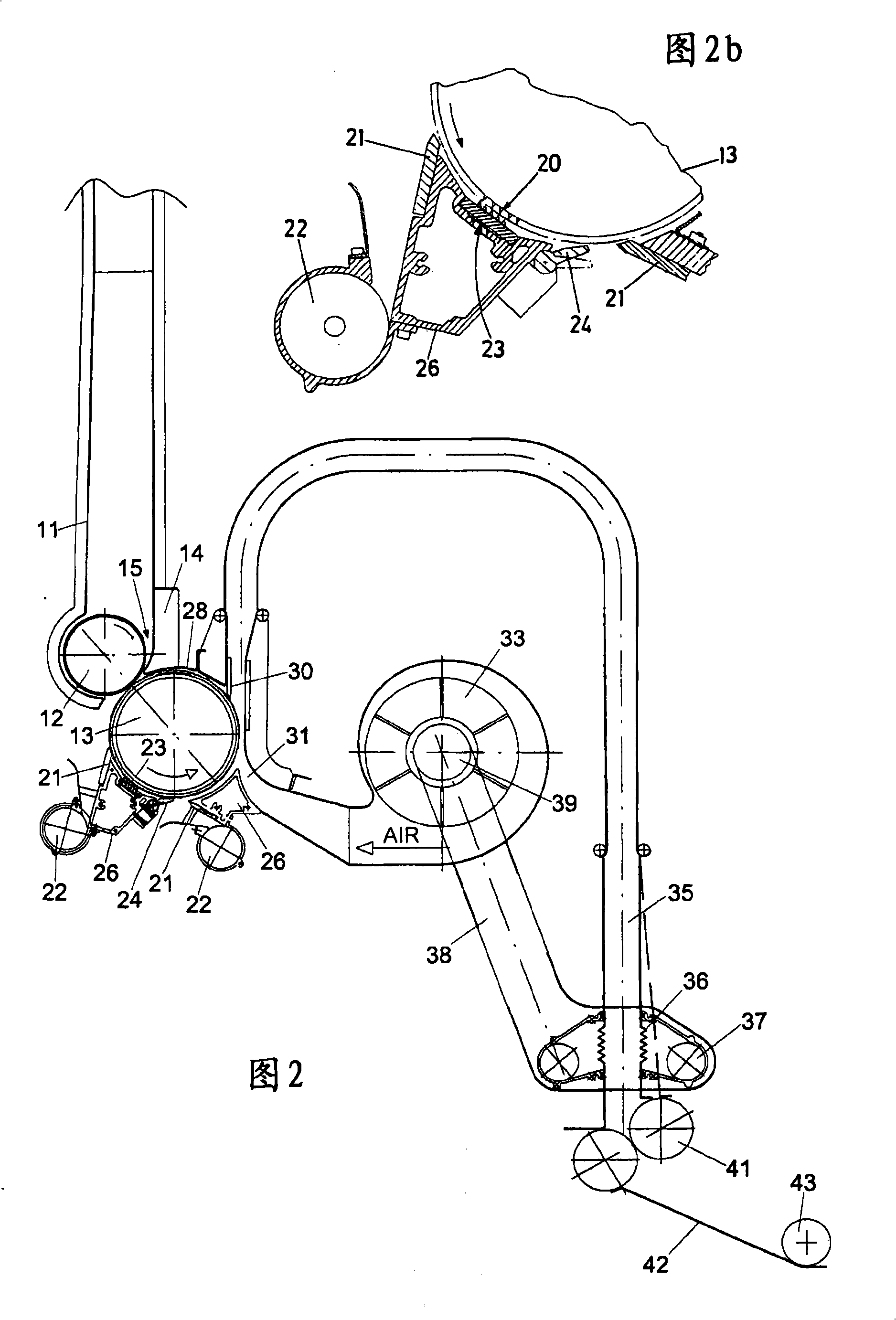

[0020] The embodiment shown in Figure 2 shows a preparation and feeding device comprising a vertical storage tank 11, in which the fibrous material is conveyed pneumatically in an air stream from the starting box 6, and is used, for example, as already described in the cited patent EP1.004.693 The fill level control technology accumulates in the end of the reservoir.

[0021] At the bottom of the drum 11 there is provided a feed drum or roller 12 which feeds the tuft fibers to an equipped drum 13 which unwinds the material and opens and cleans the picked tufts. The two drums 12 and 13 work together in rotation to take up the material and feed it forward.

[0022] The feed rollers 12 are actuated at variable rotational speeds and are made toothed or provided with serrated wires in a manner known per se. The feed rollers 12 work against the wall 14 of the end of the drum 11 to create a gap 15 between them for the passage of the fibers.

[0023] According to known solutions for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com