Vibrating spring type efficient cotton opening knocking device

A vibrating spring type and high-efficiency technology, applied in the opening and cleaning machine, fiber opening and cleaning machine, etc., can solve the problems of poor effect and low cotton opening efficiency, and achieve high efficiency, good effect, and prevent agglomeration and agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

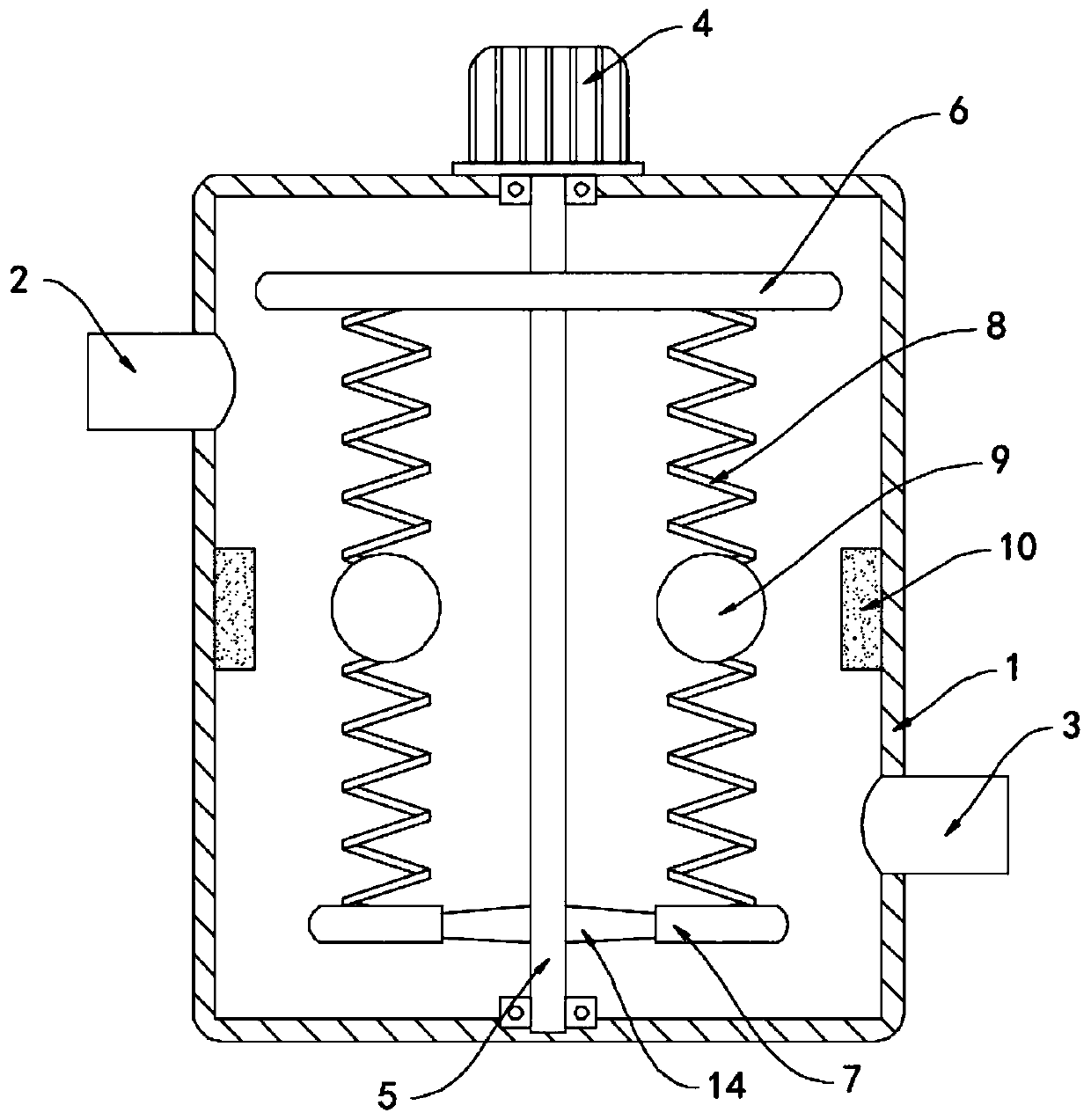

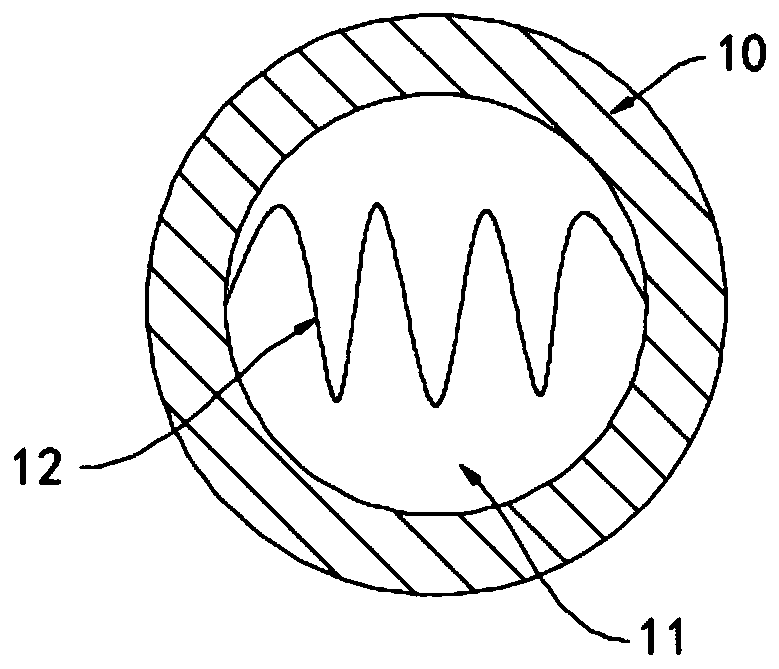

[0020] Such as Figure 1-3 As shown, a vibrating spring type high-efficiency cotton opening knocking device includes a housing 1, a feed pipe 2 and a discharge pipe 3 are fixedly connected to the side walls of the housing 1, and the top surface of the housing 1 is fixedly installed with The motor 4, the output shaft of the motor 4 extends into the casing 1 and is fixedly connected with the rotating shaft 5 coaxially. The casing 1 is respectively provided with an upper support plate 6 and a lower support plate 7 arranged horizontally, and the upper support plate 6 and the lower support plate The plates 7 are all arranged in a disc shape, and the rotating shaft 5 runs through the upper supporting plate 6 and the lower supporting plate 7 in turn and is connected to the inner bottom surface of the housing 1 in rotation. A fan 14 is fixedly installed in the lower supporting plate 7. The shaft is fixedly connected, the rotating shaft 5 is fixedly connected to the upper support plate...

Embodiment 2

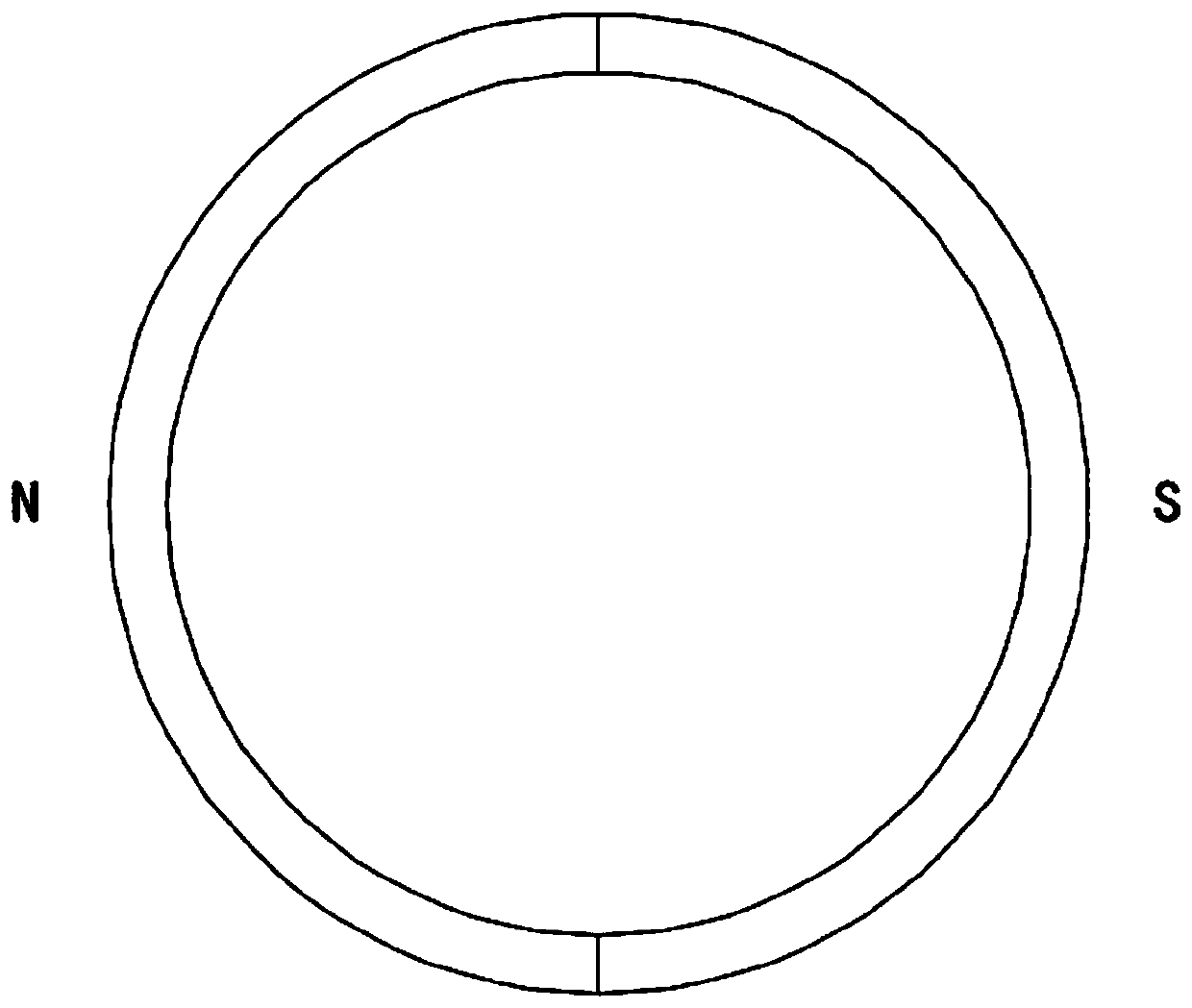

[0024] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the upper support plate 6 is fixedly sleeved with a friction ring 13, the friction ring 13 is made of rubber material, and fur is adhered to the inner wall of the housing 1. The outer wall of the friction ring 13 is in contact with the housing 1 .

[0025] In this embodiment, the motor 4 drives the friction ring 13 to rotate in the housing 1, and the friction ring 13 rubs against the inner side wall of the housing 1. According to the principle of frictional electricity generation, the rubber rod rubbed against the fur will carry a negative charge , then the surface of the friction ring 13 carries a negative charge, which can absorb the dust and impurities in the cotton, thereby playing the effect of dust removal and improving the product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com