Fiber mixed device and fiber mixed method

A blending and fiber technology, applied in the textile field, can solve problems such as poor uniformity, fabric quality damage, fiber breakage or damage, etc., to achieve the effect of improving cotton mixing efficiency, uniform fiber, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

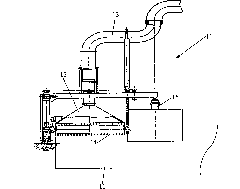

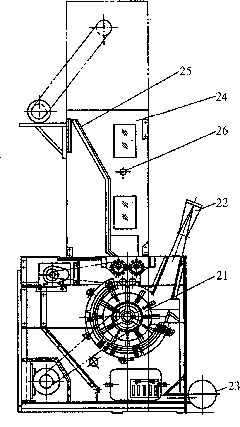

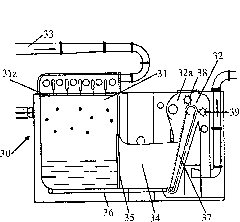

[0026] The implementation of the fiber compounding equipment of the present invention will be described below with reference to the accompanying drawings and specific examples.

[0027] The fiber compounding device according to the present invention at first comprises a first compounding device 10 (such as figure 1 As shown), it is arranged at the starting end of the fiber compounding equipment, and the fibers to be compounded will be sent into the first compounding device 10 for preliminary opening and mixing. Specifically, such as figure 1 As shown, the first mixing device 10 includes a storage part 11 for accommodating different fiber materials in proportion and a grabbing part 12 arranged above the storage part 11, and the grabbing part 12 grabs from the storage part 11. The fibrous material is transported to the transfer channel 13 leading to the downstream device (opening card device 20). Specifically, the above-mentioned storage member 11 is formed in a cylindrical sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com