Cotton cleaning method and processing device thereof

A processing equipment and cleaning method technology, applied in the direction of opening and cleaning machines, fiber opening and cleaning machines, etc., can solve the problems of reducing the quality of finished cloth, forming defects, affecting spinning, etc., and achieve the effect of improving product grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

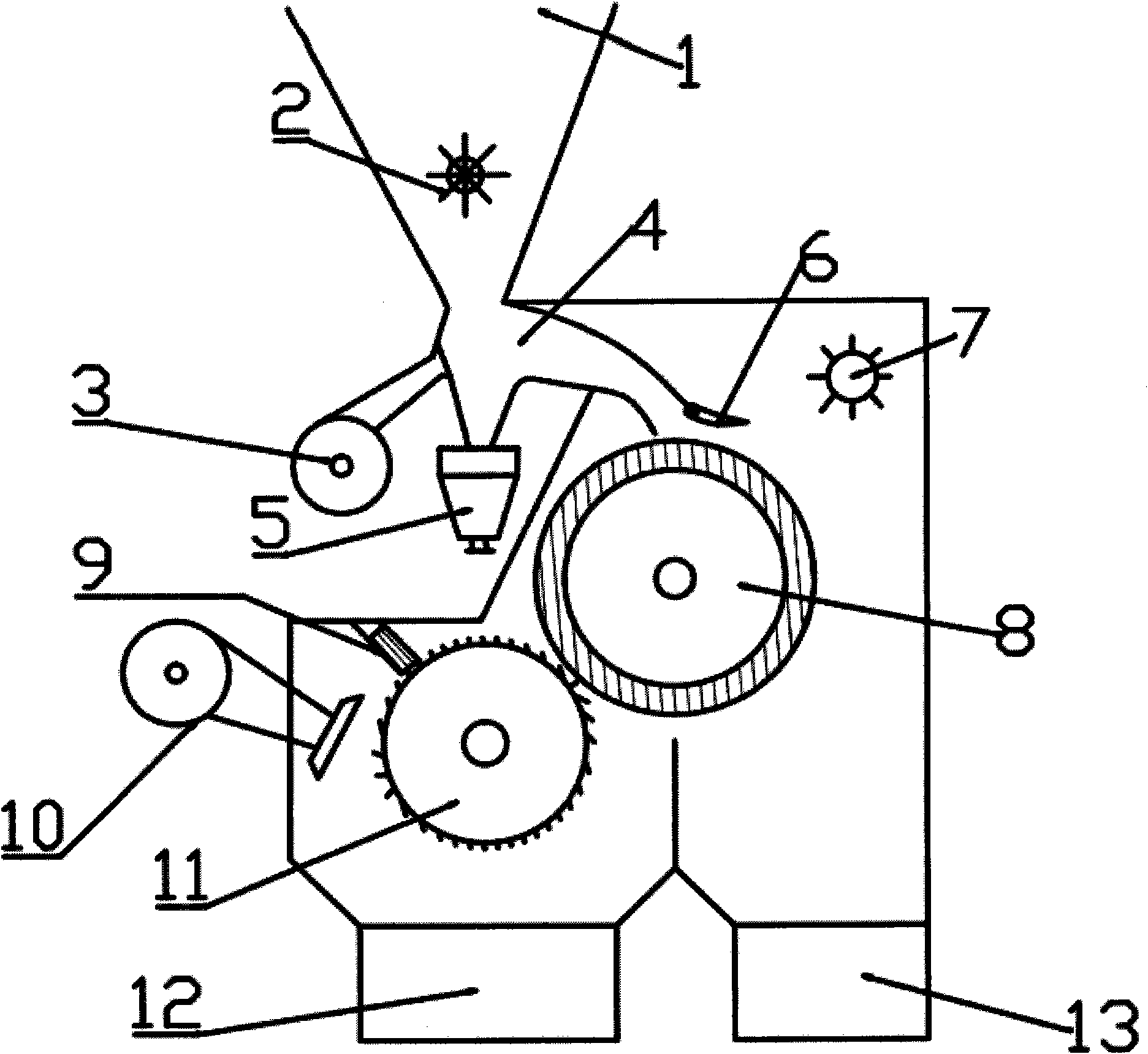

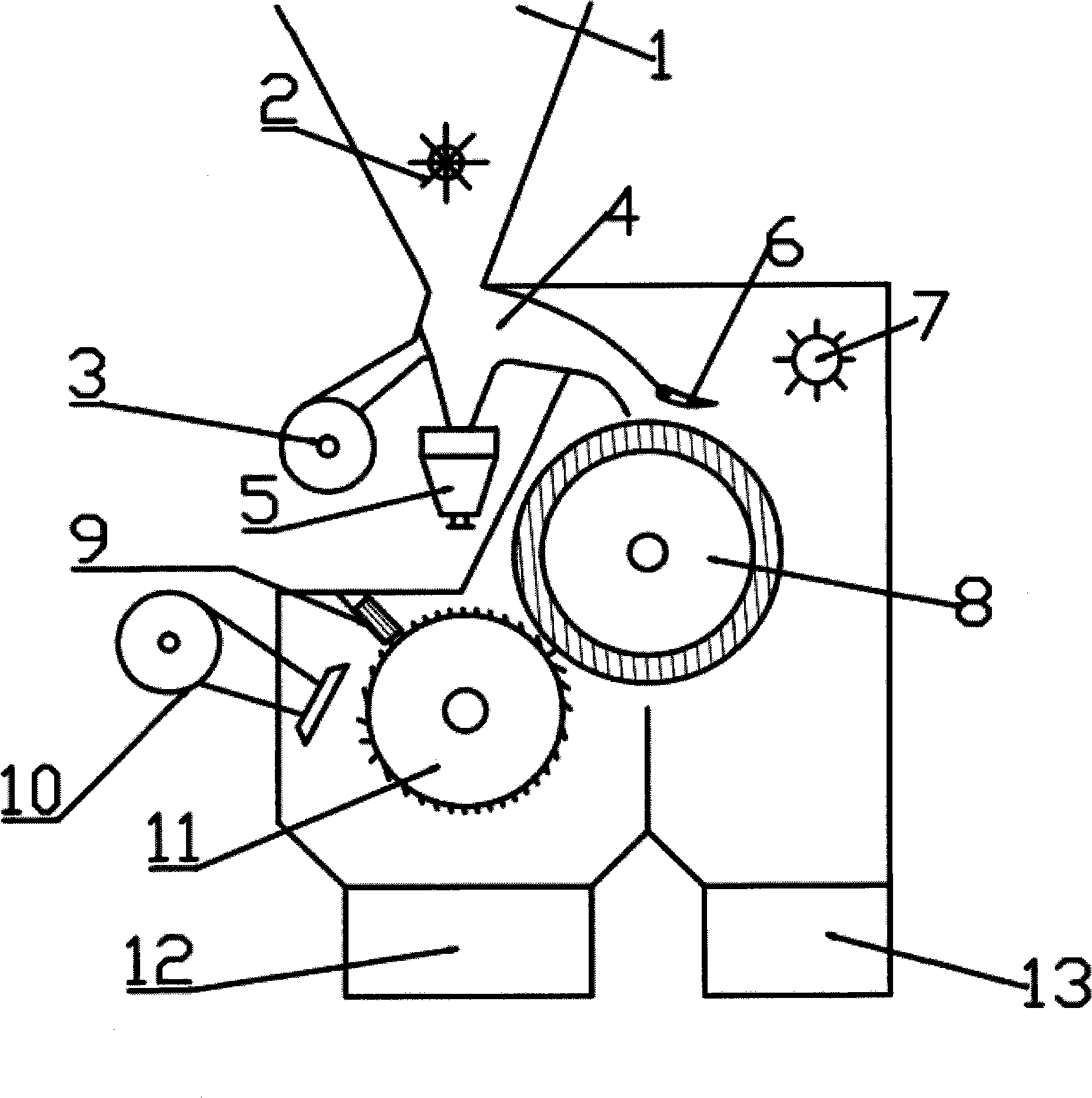

[0009] The reference numerals shown in Fig. 1 are as follows: feed box 1, opening beater 2, blower 3, winnowing room 4, impurity hopper 5, baffle plate 6, electrode emitter 7, electrode roller 8, hair brush 9, stripping Fan 10, licker-in roller 11, fiber storage bin 12, impurity bin 13.

[0010] The main features of a cotton cleaning method and its processing equipment shown in Figure 1 include: the cotton raw material enters through the feed box 1, the cotton is broken up under the action of the opening beater 2, and slowly enters the winnowing chamber 4 after combing . The cotton is affected by the airflow of the blower 3 and its own gravity during the falling process, and the heavy impurities mixed in it fall into the impurity hopper 5 which is close to the bell mouth of the blower 3, and the sorted cotton is brought to the electric separation room by the airflow , Electrode emitter 7 connects positive pole and electrode stick 8 connects negative pole, when cotton passes b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com