Plastic Fastening Device Comprising a Recycled Thermoplastic Resin

a thermoplastic resin and plastic technology, applied in the field of plastic fastening devices, can solve the problems of disadvantage, inability to be available indefinitely, and inability to meet the requirements of use, and achieve the effect of promoting compatibility between resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention relates to plastic fastening devices, assemblies of plastic fastening devices, and related methods for forming plastic fastening devices, wherein the plastic fastening devices are made of, or comprise, recycled material. Fastening devices and fastening device assemblies come in a multitude of different mechanical configurations. A few non-limiting examples are discussed below.

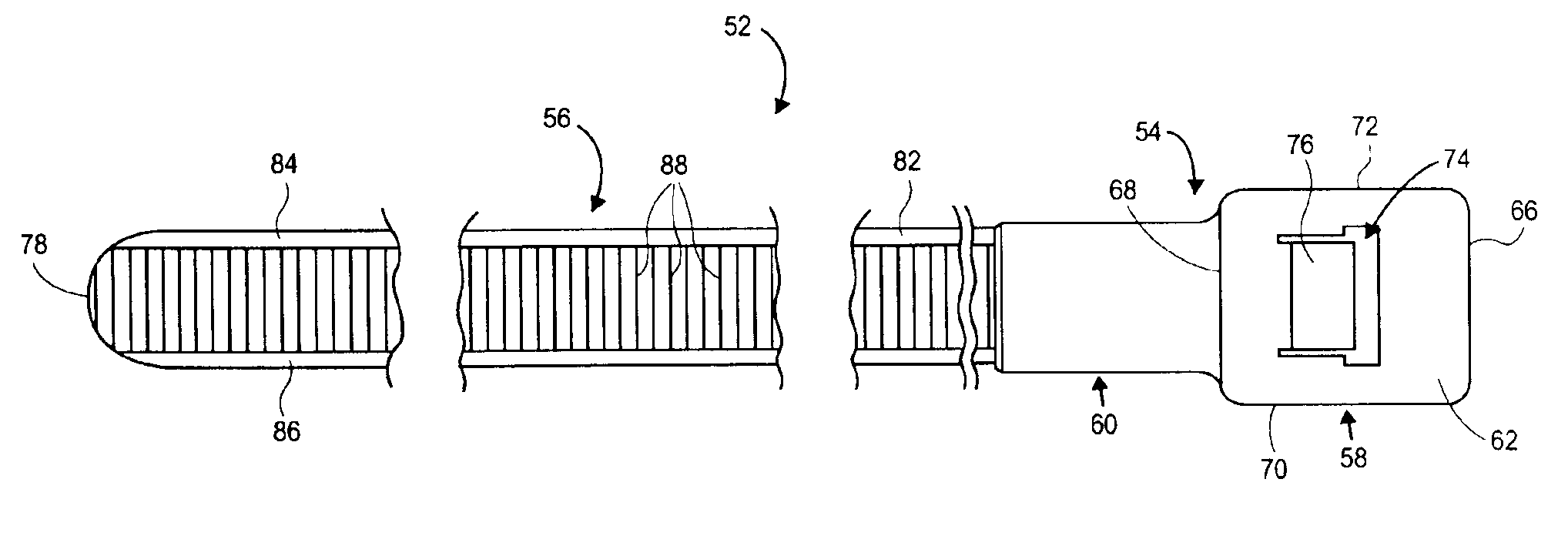

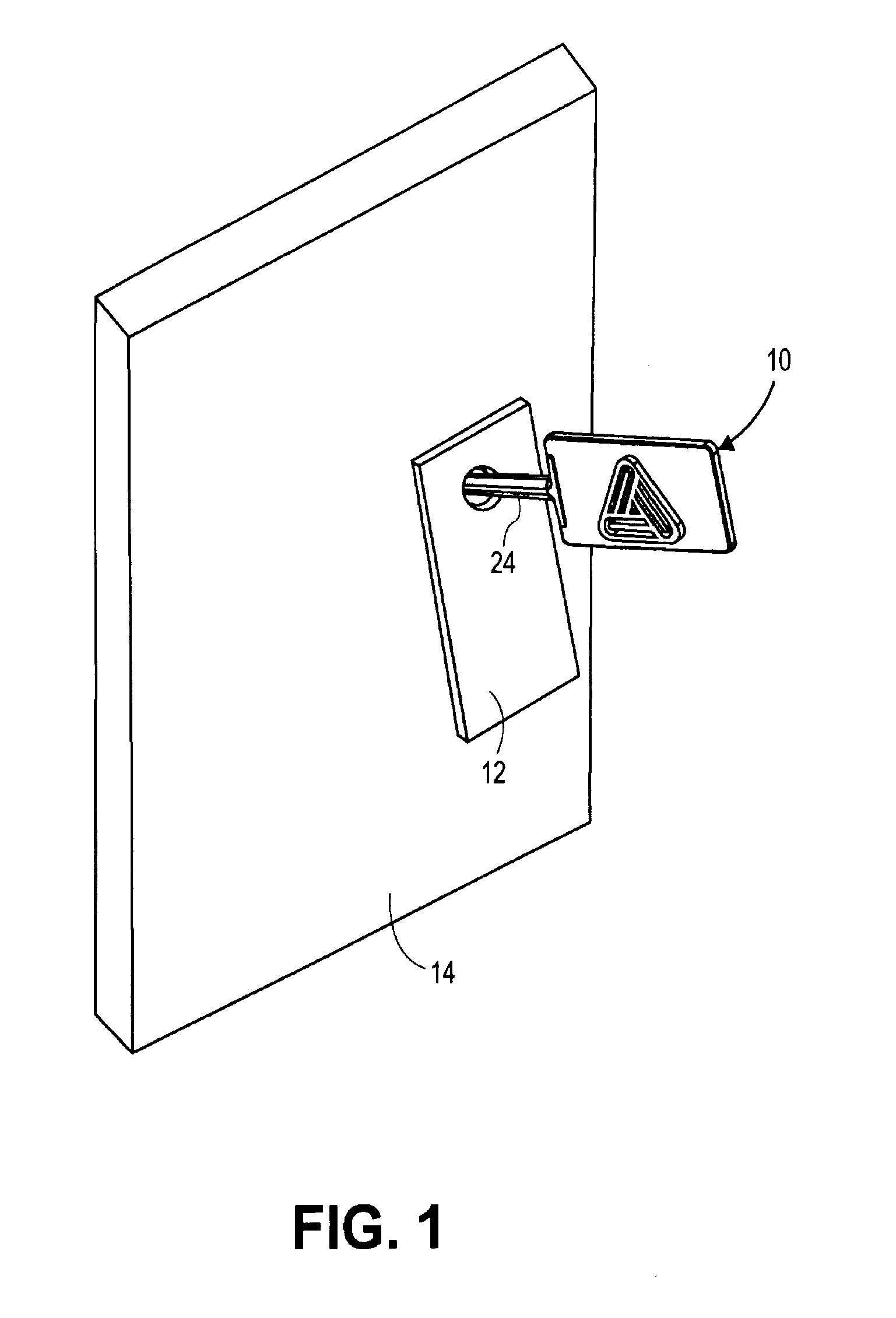

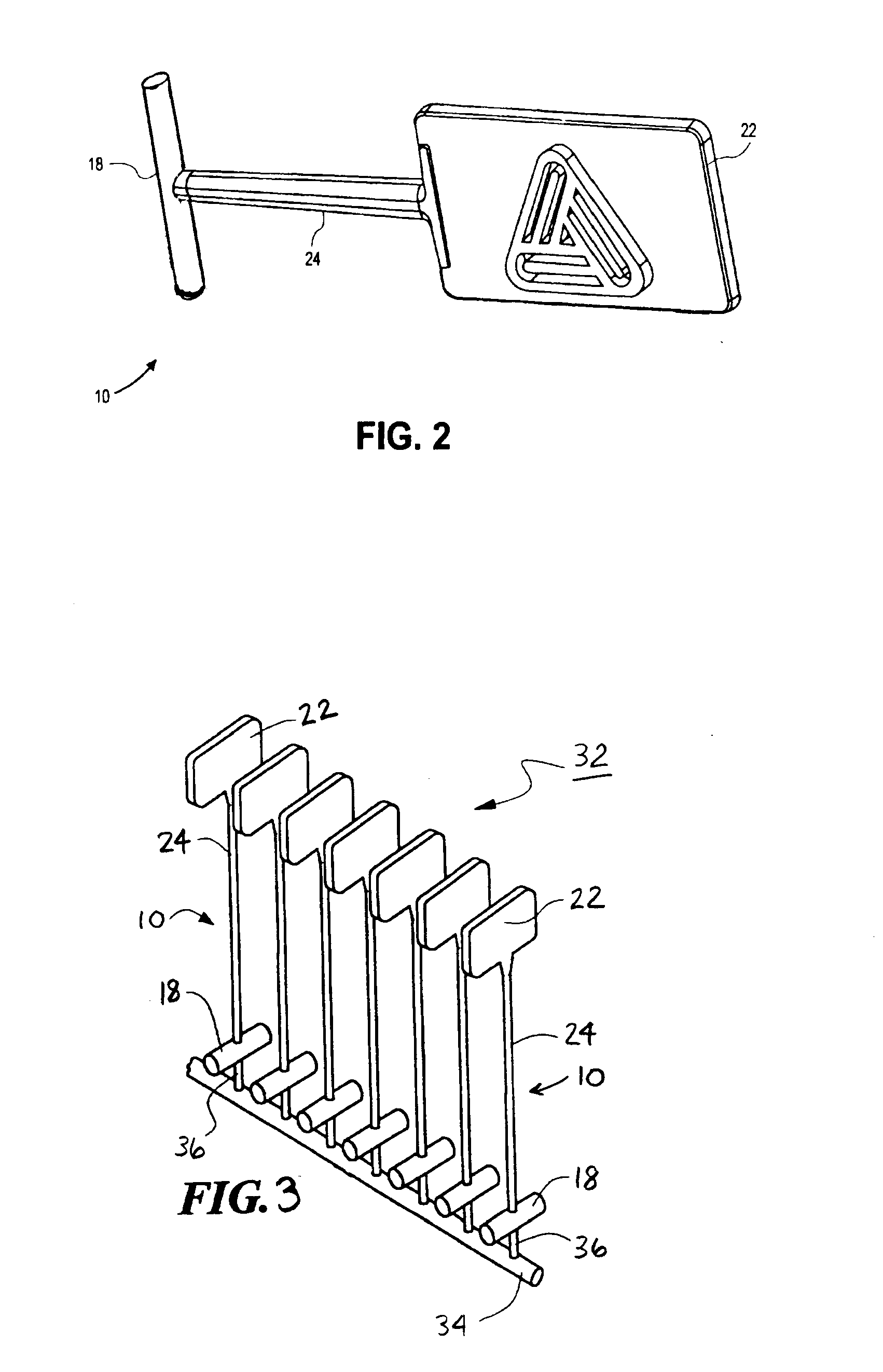

[0032]A first example of a plastic fastening device according to the invention is a plastic fastener of the type used to attach a merchandise tag to a piece of fabric, such as an article of clothing, product label, and the like. This type of fastener includes, for example, an elongated plastic member having a first end shaped to define a crossbar, also known as a “T-bar,” a second end shaped to define an enlarged paddle, and a thin filament portion that interconnects the crossbar and the paddle. As will be described further below, the crossbar is adapted to be inserted first through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com