Method for treating fermentation industry waste water and producing algae powder by using microalgae

A technology for industrial wastewater and fermentation plants, applied in energy wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Good quality effect, ingenious and unique design, and small shearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

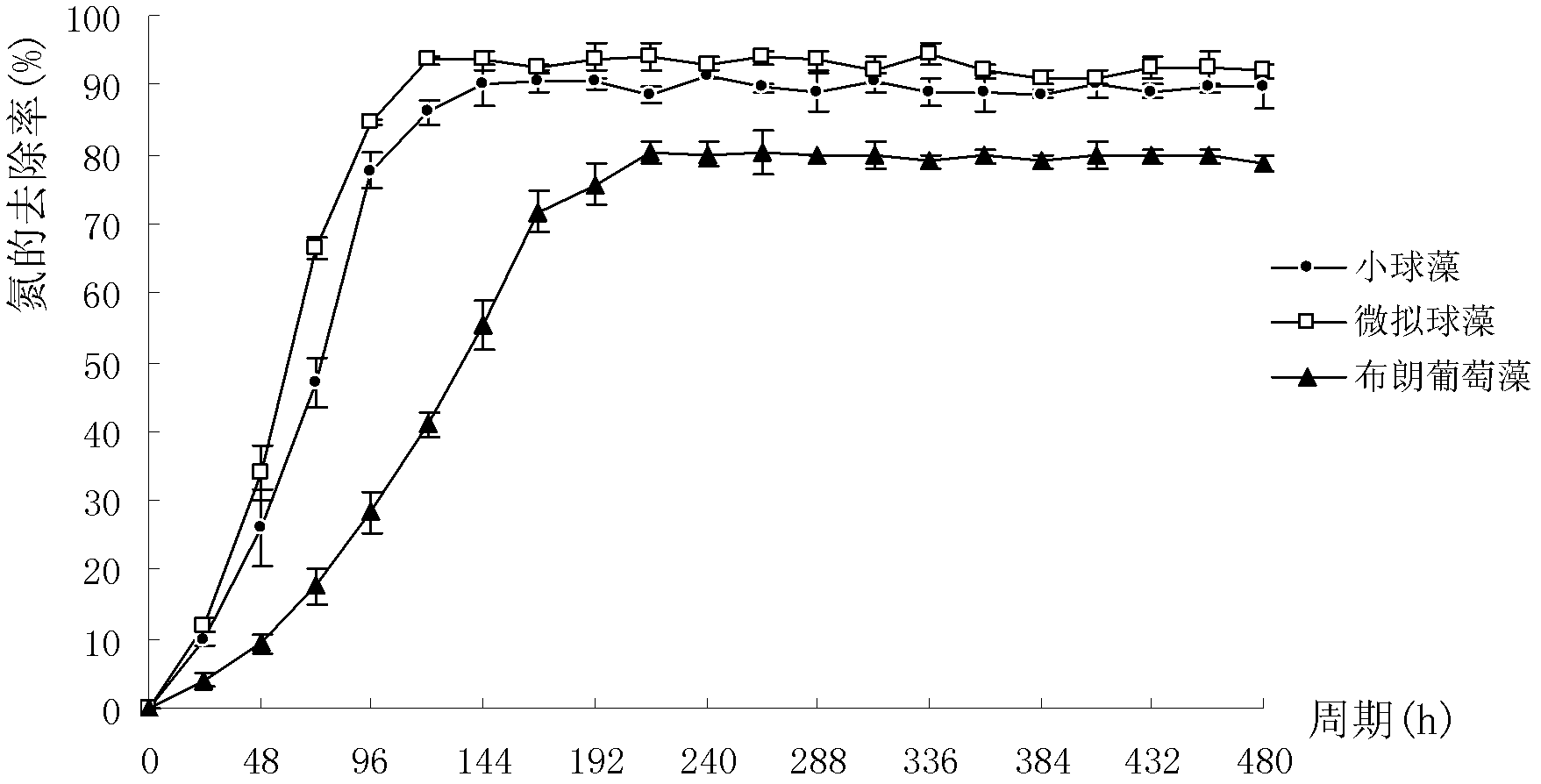

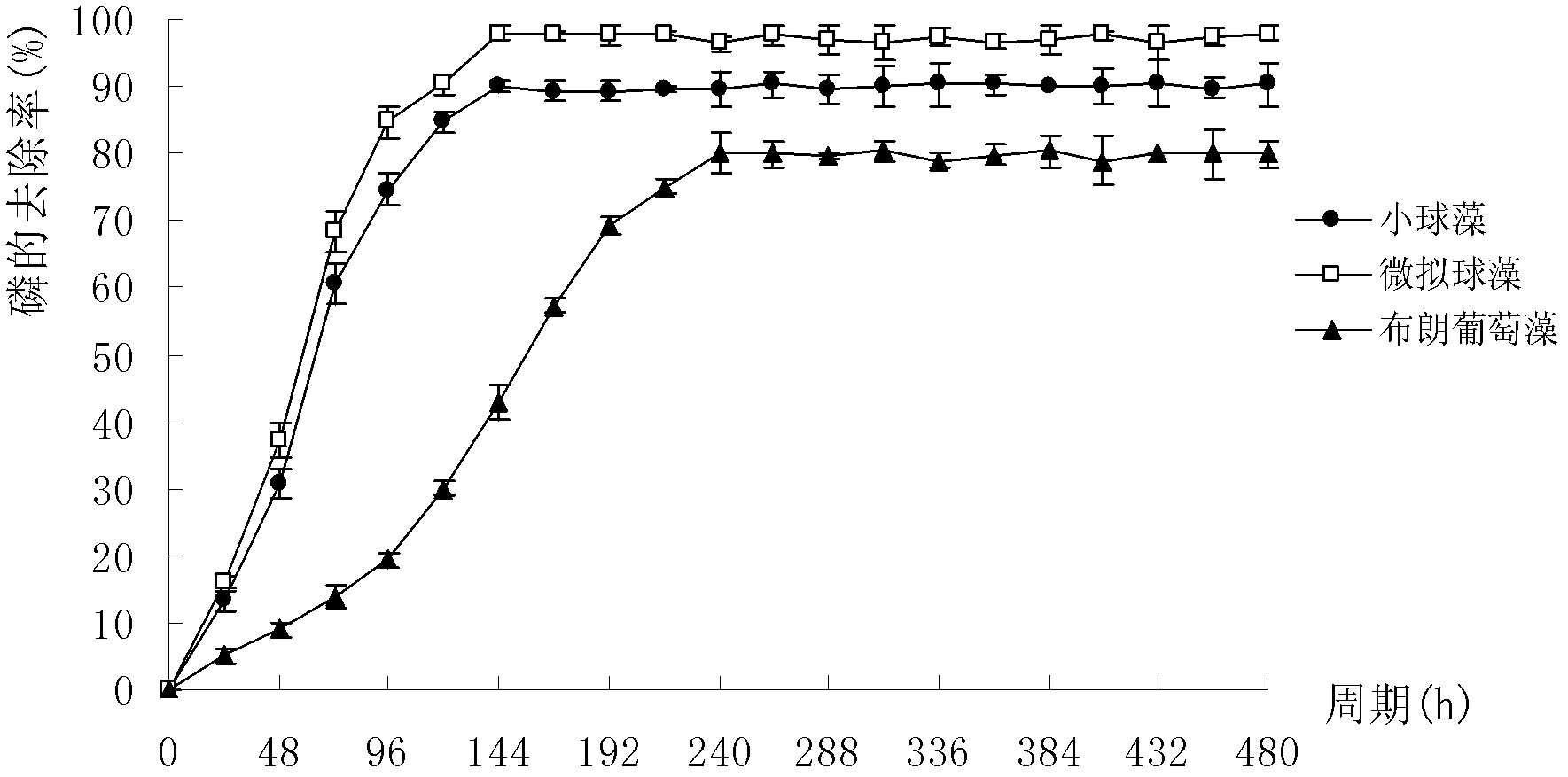

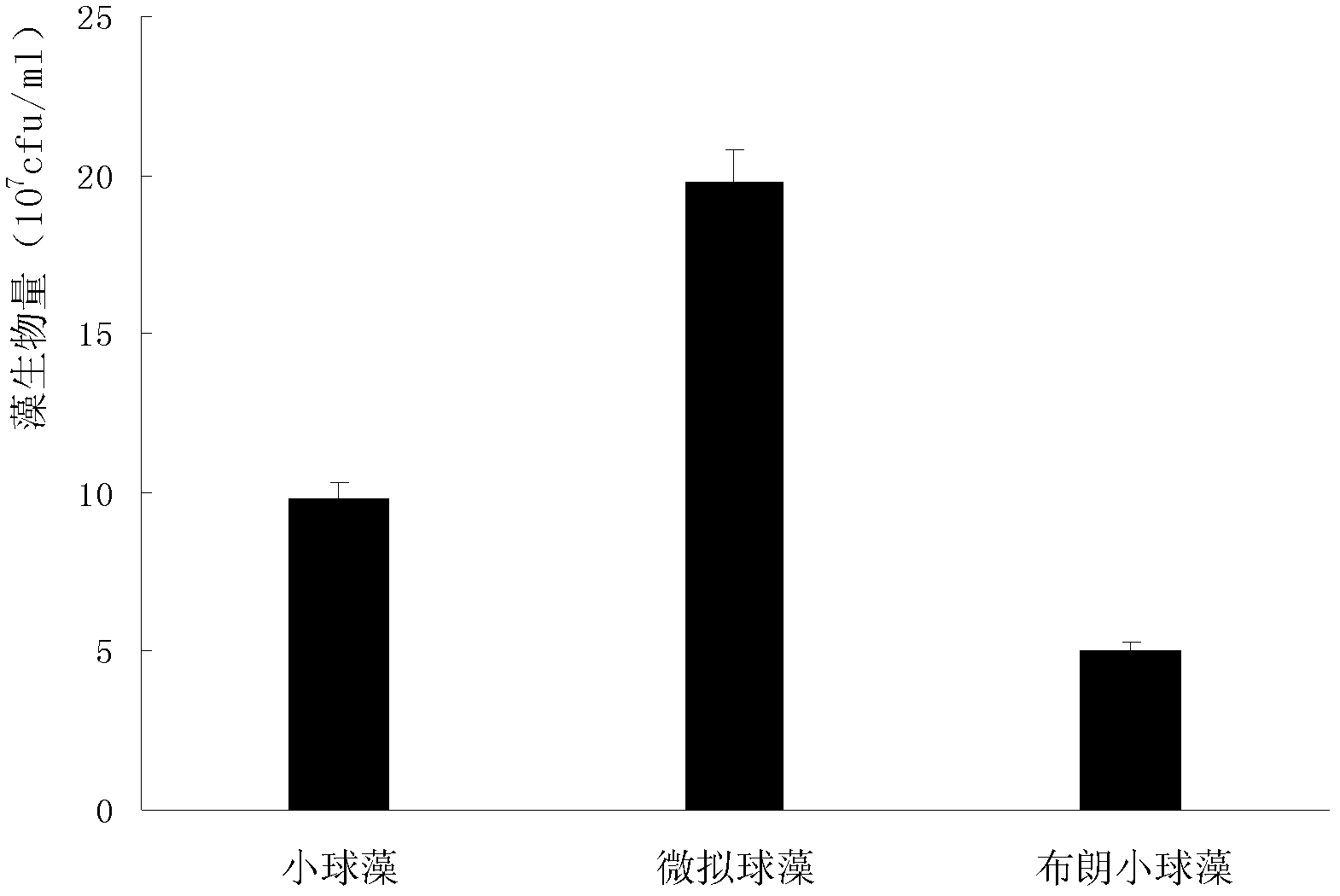

[0067] Three microalgae, Chlorella autotuophica, Nannochloropsis salina and Botyococcus Braunii were cultivated by the same process as follows, with an initial inoculation density of 1.0×10 6 cfu / ml, the culture conditions are as follows: the light cycle is 16h:8h, the light intensity is 5000lux, the culture temperature is 12°C, the pH is 6.0, and the gas ventilation rate is 0.01VVm. After continuous culture for 480 hours, see Figure 1A , 1B , 1C, 1D, 1E, 1F, and 1G.

[0068] Depend on Figure 1A The analysis shows that during the 0-144h culture process, as the culture time prolongs, the nitrogen consumption rate of autotrophic Chlorella and Nannochloropsis is accelerated, and the nitrogen consumption rate is the fastest between 48h and 96h, reaching 144h. The maximum nitrogen removal rates were 90.0% (W) and 94.0% (W), respectively, and then maintained at this level. However, during the 0-216h culture period, the nitrogen consumption rate of Botrytis braziliana accelerated...

Embodiment 2

[0073] Batch fermentation and continuous fermentation were adopted to moderately dilute under the same culture conditions, and the fermented industrial waste water after filtering out miscellaneous bacteria or algae was used as the culture medium, and the cultured concentration was 3.0×10 7 Cfu / ml high-concentration oleaginous autotrophic microalgae were inoculated into the photoreactor, the culture temperature was 25°C, the pH was 7.0, the photoperiod was 14h:10h, the light intensity was 10000lux, and the ventilation volume was 0.1VVm to cultivate autotrophs Chlorella, cultivated for 480h, the relationship between nitrogen and phosphorus removal efficiency (% (W)) and algal biomass see Figures 2A-2C shown.

[0074] Depend on Figure 2A According to the analysis, with the prolongation of the culture time, the utilization of nitrogen and phosphorus by the two culture methods was accelerated. In the process of batch culture, the utilization rate of nitrogen increased continuo...

Embodiment 3

[0078] The continuous fermentation culture method is used to dilute moderately under the same culture conditions, and the fermented industrial wastewater after filtering out bacteria or algae is used as the medium, and the cultured concentration is 1.0×10 8 The high concentration of cfu / ml oleaginous autotrophic microalgae was inoculated into the photoreactor, the culture temperature was 35°C, the pH was 7.5, the light cycle was 10h:14h, the light intensity was 15000.0lux, and the ventilation volume was 0.2VVm. To raise Chlorella, the batch culture of Chlorella vulgaris C9-JN2010 (preservation number: CCTCC NO: M 2010373) was carried out in a transparent trough photobioreactor and an airlift photobioreactor respectively, and the culture period was 240h. Nitrogen, phosphorus removal effect and biomass relationship see Figure 3A-3B shown.

[0079] Depend on Figure 3A According to the analysis, in the process of batch cultivation using transparent trough photobioreactor, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com