Environment-friendly and high-efficiency production method of antimony white by using Sb and As-containing ash

A technology of soot and antimony white, which is applied in the field of green and efficient production of antimony white from antimony arsenic soot, achieving the effects of high energy efficiency, strong adaptability of raw materials, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

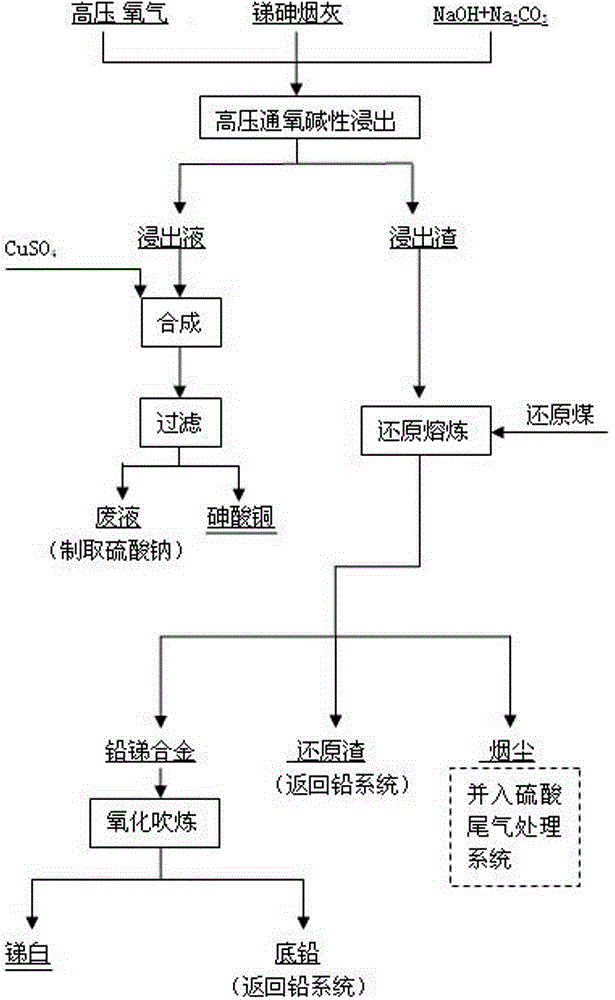

Method used

Image

Examples

Embodiment 1

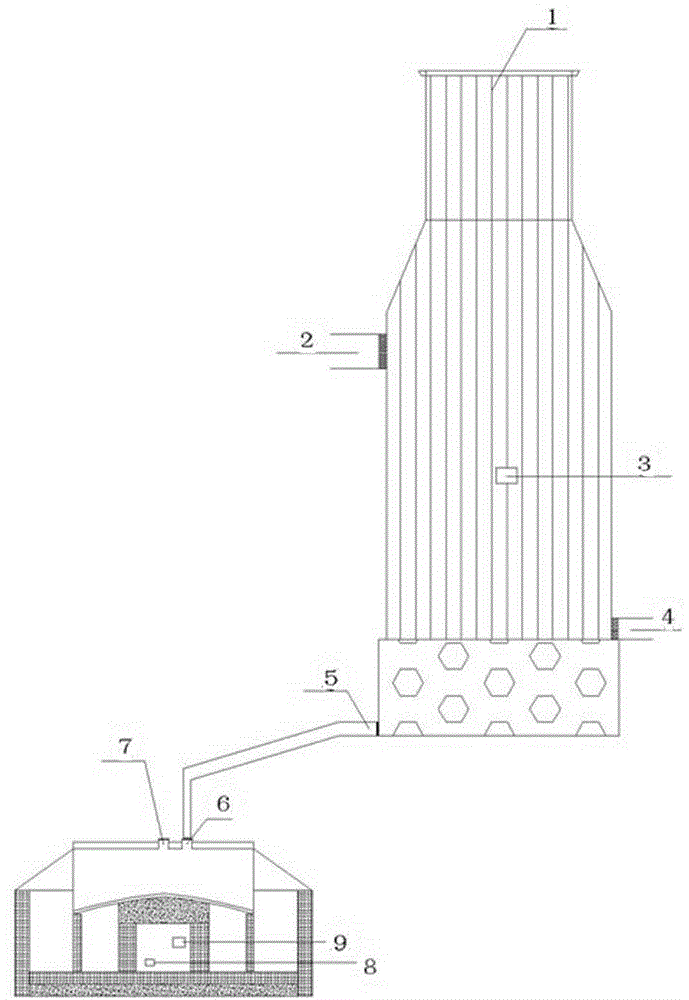

[0026] Antimony arsenic soot 1000 kg, containing 63% antimony, 15% arsenic, 2% lead, liquid-solid volume mass ratio 8:1ml / g, sodium hydroxide 3 mol / L, sodium carbonate 2 mol / L, temperature 100°C, The oxygen pressure is 2 MPa, the leaching time is 2 h, and the arsenic leaching rate is 98.5%. Sulfuric acid was added to adjust the pH of the leaching solution to 3, the temperature was 95°C, and the reaction time was 2 hours, 923 kg of copper arsenate was synthesized, and the recovery rate of arsenic was 98.2%. The leaching slag and the reduced coal are batched, and the mass ratio of the batching is leaching slag:reduced coal=100:5, which is added to the inner melting furnace for reduction smelting, and the temperature of the inner melting furnace is controlled at 1100°C. The lead-antimony alloy produced was put into the oxidation pot, and the antimony content in the alloy liquid was controlled to 32% by adding refined lead, and the temperature of the alloy liquid was controlled at...

Embodiment 2

[0028] Antimony arsenic soot 1000 kg, containing 58% antimony, 17% arsenic, 1% lead, liquid-solid volume mass ratio 10:1ml / g, sodium hydroxide 2 mol / L, sodium carbonate 1 mol / L, temperature 105°C, The oxygen pressure is 1.5 MPa, the leaching time is 2 h, and the arsenic leaching rate is 98%. Sulfuric acid was added to adjust the pH of the leaching solution to 3, the temperature was 95°C, and the reaction time was 2 hours. 1040 kg of copper arsenate was synthesized, and the recovery rate of arsenic was 97.8%. The leached slag and reduced coal are batched, and the batching mass ratio is leached slag: reduced coal = 100:3, which is added to the inner melting furnace for reduction smelting, and the temperature of the inner melting furnace is controlled at 1050°C. The lead-antimony alloy produced was put into the oxidation pot, and the antimony content in the alloy liquid was controlled by adding refined lead to 30%, and the temperature of the alloy liquid was controlled at 900°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com