Method for preparing fish flavor nutritional condiment

A fish and flavor technology, applied in the field of fish flavor nutritional condiments, can solve problems such as environmental pollution and resource waste, achieve the effects of compact and reasonable process, elimination of fishy and bitter taste, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

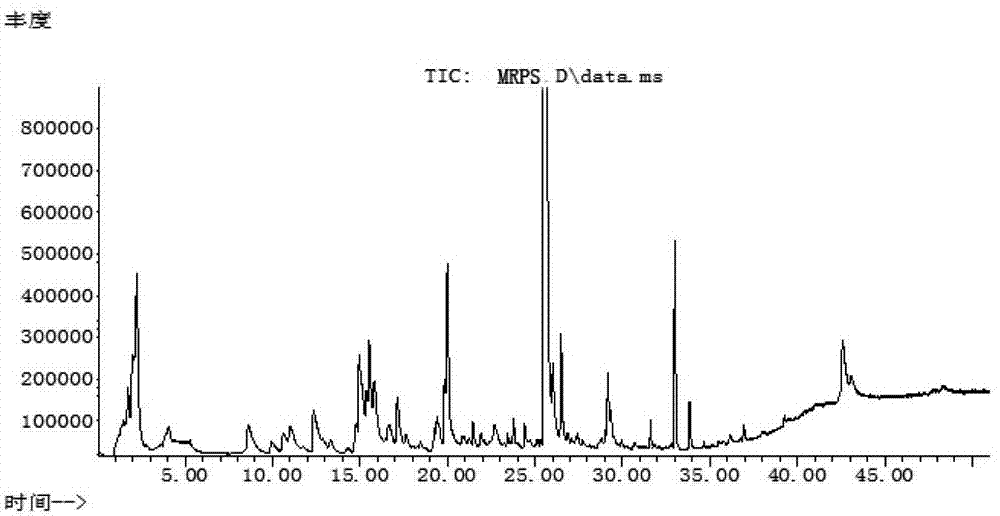

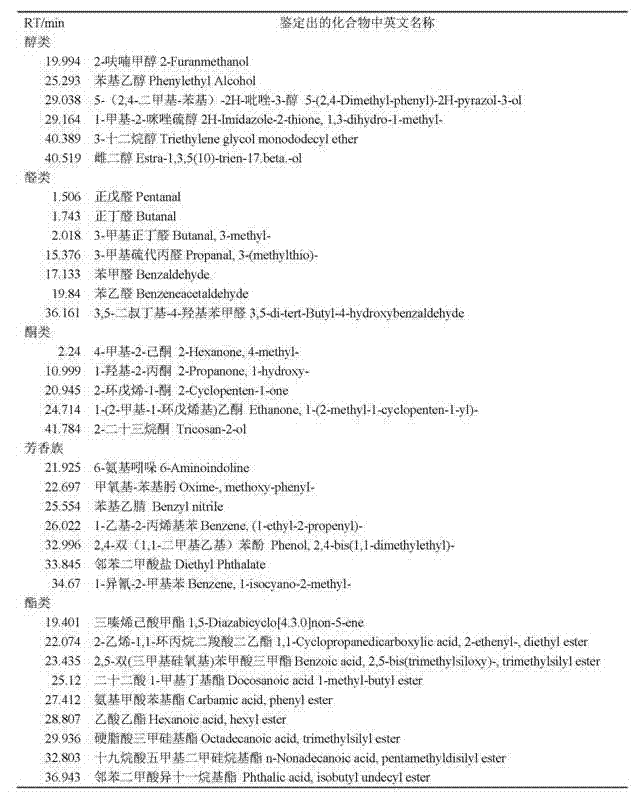

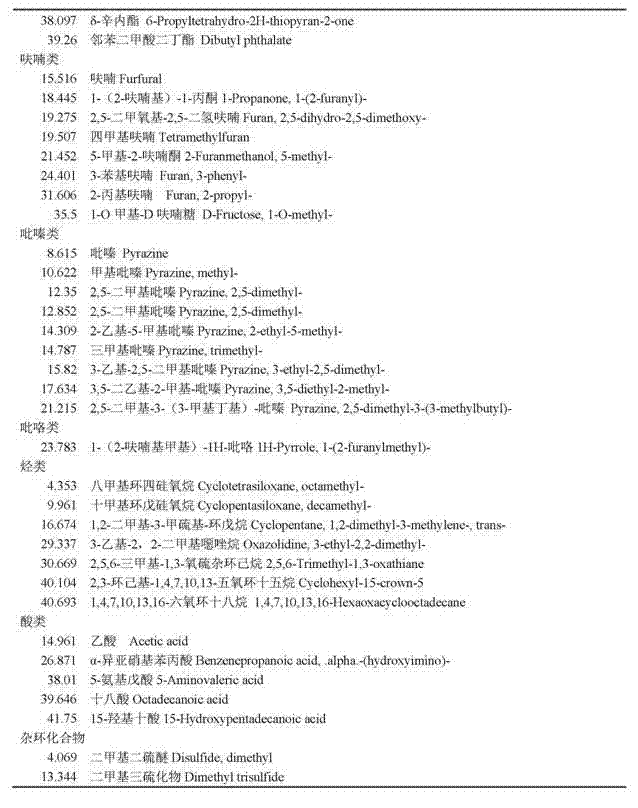

Image

Examples

Embodiment 1

[0016] The invention relates to a method for preparing fish-flavored nutritious condiment using leftover fish steaks and minced meat produced during the processing of tilapia fillets as raw materials, which comprises the following steps:

[0017] (1) Raw material pretreatment: Take 20kg of fresh tilapia fish steaks and minced meat, grind them through a 5mm aperture meat grinder, and send them into an enzymatic hydrolysis tank as raw materials, add 60kg of water to fully mix to make a feed liquid, and heat the feed liquid to 60°C.

[0018] (2) Protease compound enzymolysis: Add 600U / g raw material flavor protease and 1500U / g raw material papain respectively, adjust the pH of the feed solution to 7.5, temperature 60°C, constant temperature enzymatic hydrolysis for 3 hours, boil for 5 minutes, and cool to 30°C;

[0019] (3) Maillard reaction: the enzymatic solution is filtered through a 40-mesh vibrating sieve and sent to the reactor, and 0.8kg of glucose, 0.4kg of xylose, 1.2kg...

Embodiment 2

[0023] The invention relates to a method for preparing fish-flavored nutritious condiment using leftover fish steaks and minced meat produced during the processing of tilapia fillets as raw materials, which comprises the following steps:

[0024] (1) Raw material pretreatment: Take 30kg of frozen tilapia fish steaks and minced meat, cut them into pieces, and then grind them with a 5mm aperture meat grinder as raw materials and send them to the enzymatic hydrolysis tank, add 30kg of water to fully mix them into ingredients liquid, and the temperature of the feed liquid was raised to 50°C.

[0025] (2) Protease compound enzymolysis: Add 400U / g raw material flavor protease and 1300U / g raw material papain respectively, adjust the pH of the feed solution to 6.5, temperature 50°C, constant temperature enzymatic hydrolysis for 6 hours, boil for 15 minutes, and cool to 50°C.

[0026] (3) Maillard reaction: the enzymatic solution is filtered through a 60-mesh vibrating sieve and sent t...

Embodiment 3

[0030] The invention relates to a method for preparing fish-flavored nutritious condiment by using leftover fish rafts produced during the processing of tilapia fillets as raw materials, which comprises the following steps:

[0031] (1) Raw material pretreatment: take 50kg of fresh tilapia fish fillet, grind it through a 5mm aperture meat grinder, and send it to an enzymatic hydrolysis tank as raw material, add 100kg of water to fully mix to make a feed liquid, and raise the temperature of the feed liquid to 55°C.

[0032] (2) Protease compound enzymolysis: add 500U / g raw material flavor protease and 1400U / g raw material papain respectively, adjust the pH of the feed solution to 7.0, temperature 55°C, constant temperature enzymolysis for 4.5hr, boil for 10min, cool to 40°C ;

[0033] (3) Maillard reaction: The enzymatic solution is filtered through a 40-mesh vibrating sieve and sent to the reactor, and 1.34kg of glucose, 0.66kg of xylose, 2kg of glutamic acid, 1.5kg of alanine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com