Method for extracting flavor peptide by utilizing low-value marine products

A seafood, low-value technology, applied in the direction of bacteria, application, food ingredients used in food preparation, can solve the problems of solvent residue, protein activity destruction, unsatisfactory effect, etc., achieve mild reaction conditions, remove fishy odor, high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

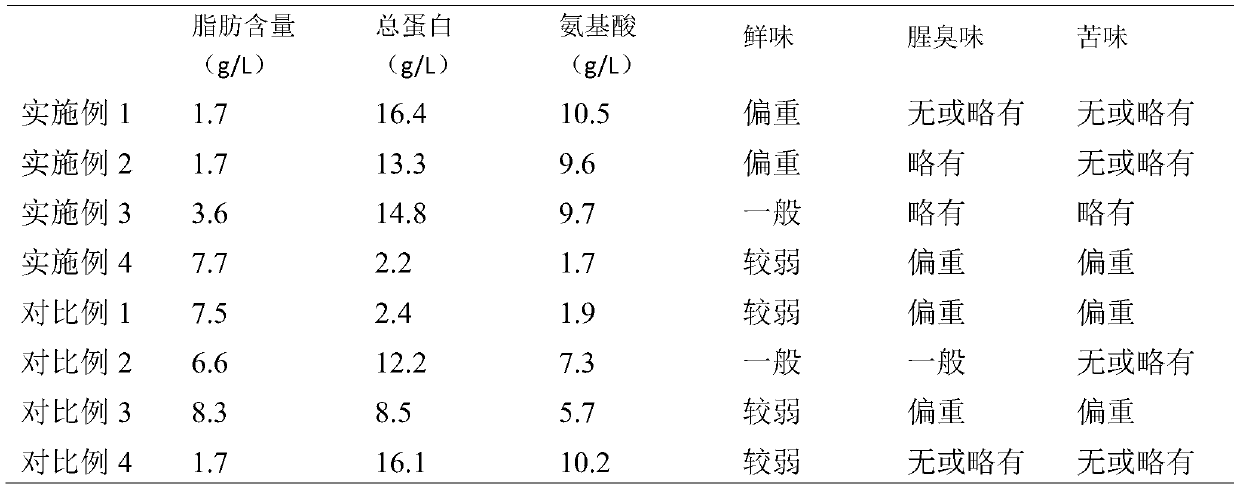

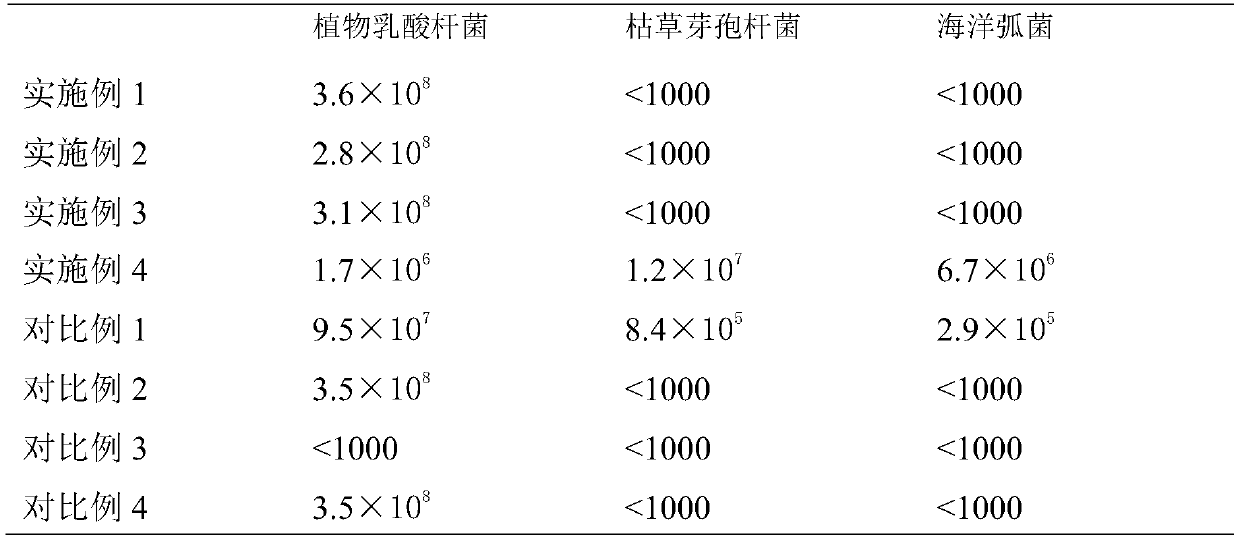

Embodiment 1

[0046] A method for extracting flavor peptides from low-value seafood, comprising the steps of:

[0047] (1) Take the krill sold in the market as the object, screen it, wash it, crush it, filter it with 50 mesh, add water at a weight ratio of 1:4 and mix it into the raw material to be fermented, and then pump 400L of the raw material to be fermented into the fermenter;

[0048] (2) acid adjustment: measure the pH value, add citric acid to adjust the acid to pH7.0;

[0049] (3) Adding a fermentation regulator: mix inulin, lactose, and nisin in parts by weight of 50, 35, and 20 to configure a fermentation regulator, and use 0.1% (mass volume fraction, unit g) of the raw material to be fermented / L) added to the fermenter, mixed evenly with the raw materials to be fermented;

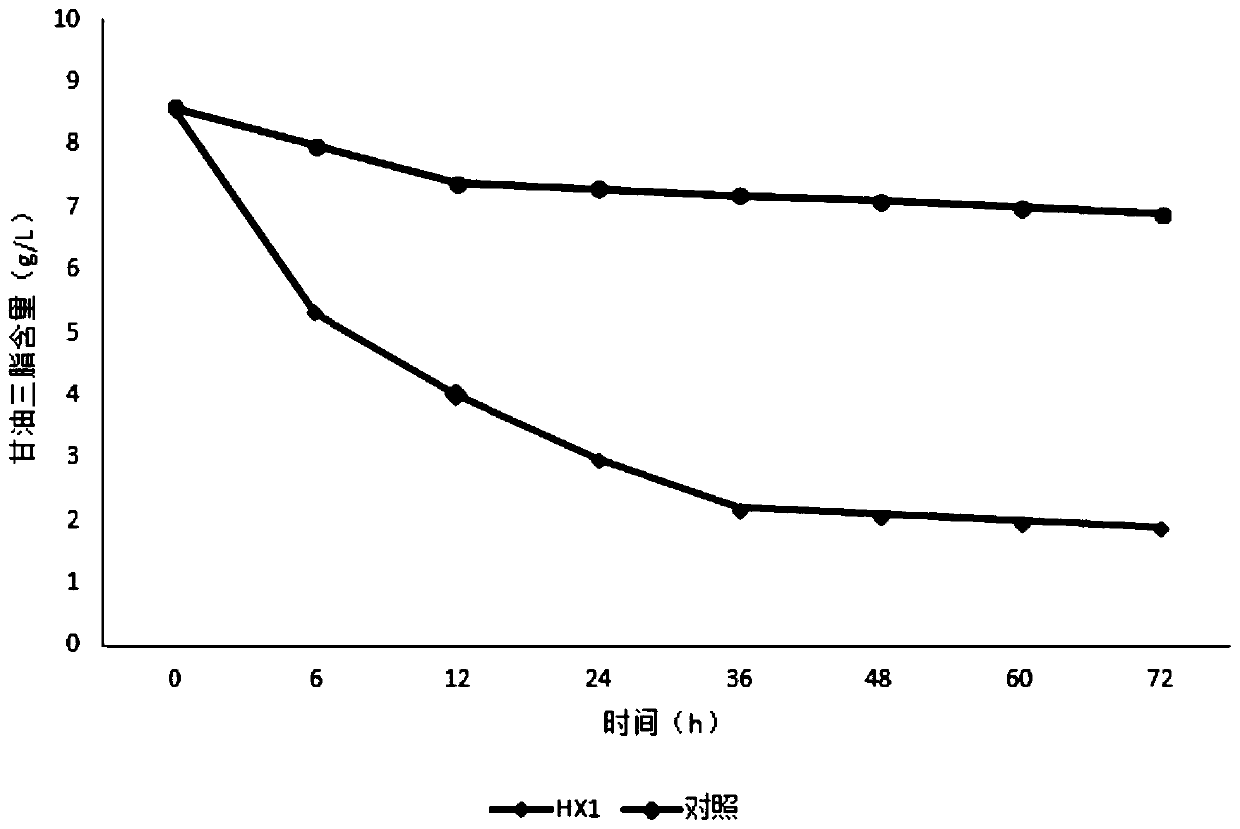

[0050] (4) Adding Lactobacillus plantarum HX1: Lactobacillus plantarum HX1 was seed-cultured in advance until the strain concentration was 2.0×10 8 CFU / mL, the bacterium liquid is added in the fermented m...

Embodiment 2

[0057] A method for extracting flavor peptides from low-value seafood, comprising the steps of:

[0058] (1) Take the krill sold in the market as the object, screen it, wash it, crush it, filter it with 50 mesh, add water at a weight ratio of 1:5 and mix it into the raw material to be fermented, and then pump 400L of the raw material to be fermented into the fermenter;

[0059] (2) acid adjustment: measure the pH value, add citric acid to adjust the acid to pH6.0;

[0060] (3) Adding a fermentation regulator: mix inulin, lactose, and nisin in parts by weight of 55, 30, and 30 to configure a fermentation regulator, and use 0.15% (mass volume fraction, unit g) of the raw material to be fermented / L) added to the fermenter, mixed evenly with the raw materials to be fermented;

[0061] (4) Adding Lactobacillus plantarum HX1: Lactobacillus plantarum HX1 was seed-cultured in advance until the strain concentration was 9.0×10 8 CFU / mL, the bacterium liquid is added in the fermented ...

Embodiment 3

[0068] A method for extracting flavor peptides from low-value seafood, comprising the steps of:

[0069] (1) Take the krill sold in the market as the object, screen it, wash it, crush it, filter it with 50 mesh, add water in a weight ratio of 1:3 and mix it into the raw material to be fermented, and then pump 400L of the raw material to be fermented into the fermenter;

[0070] (2) acid adjustment: measure the pH value, add citric acid to adjust the acid to pH6.5;

[0071] (3) Add fermentation regulator: mix inulin, lactose, and nisin in parts by weight of 45, 40, and 20 to configure a fermentation regulator, and use 0.2% (mass volume fraction, unit g) of the raw material to be fermented / L) added to the fermenter, mixed evenly with the raw materials to be fermented;

[0072] (4) Adding Lactobacillus plantarum HX1: Lactobacillus plantarum HX1 was seed-cultured in advance until the strain concentration was 1.0×10 8 CFU / mL, the bacterium liquid is added in the fermented mash o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com