Method for preparing graphene nanobelt

A technology of graphene nanoribbons and carbon nanotubes, which is applied in the field of preparation of graphene nanoribbons, and can solve problems such as application limitations and lack of band gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

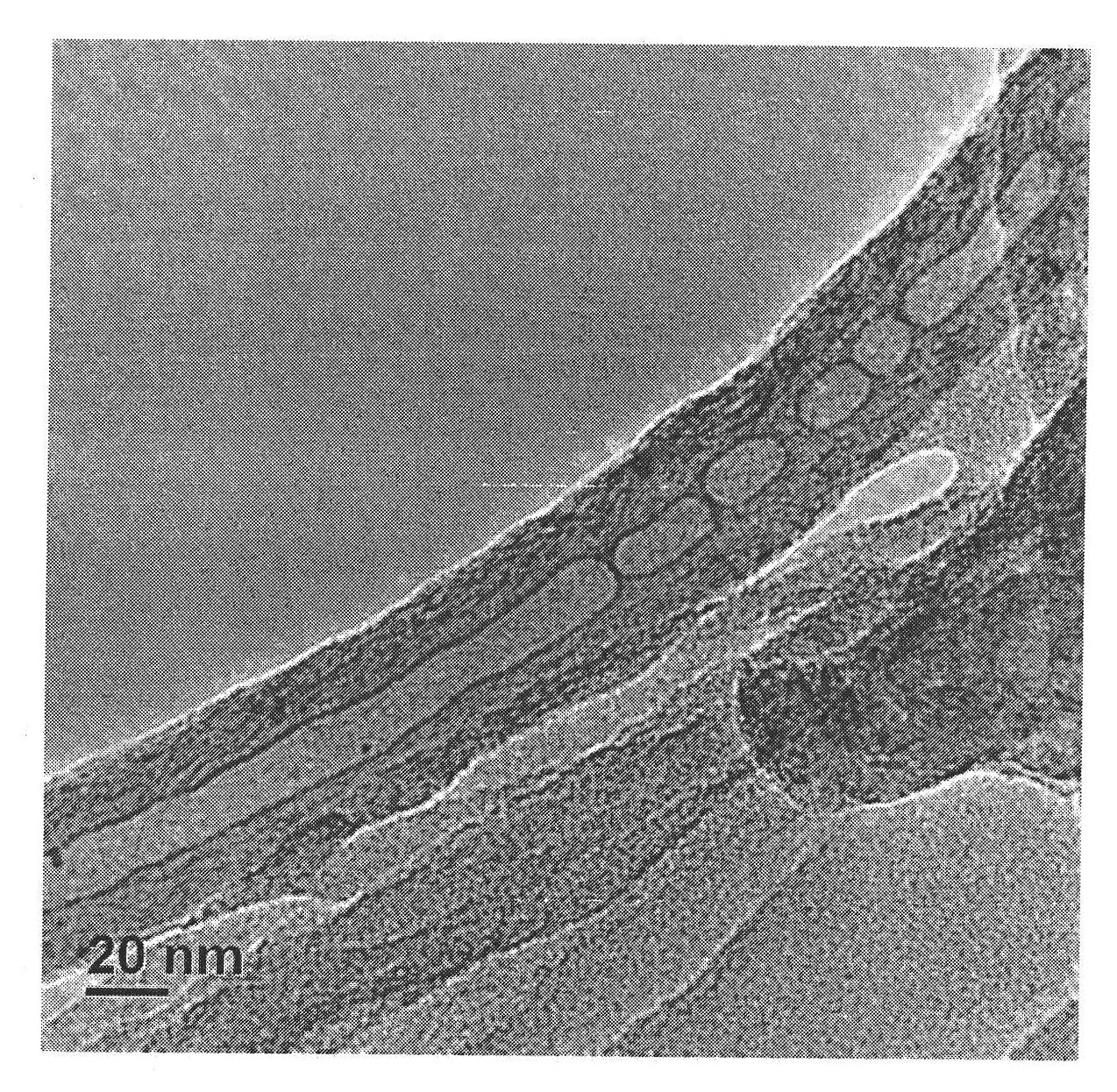

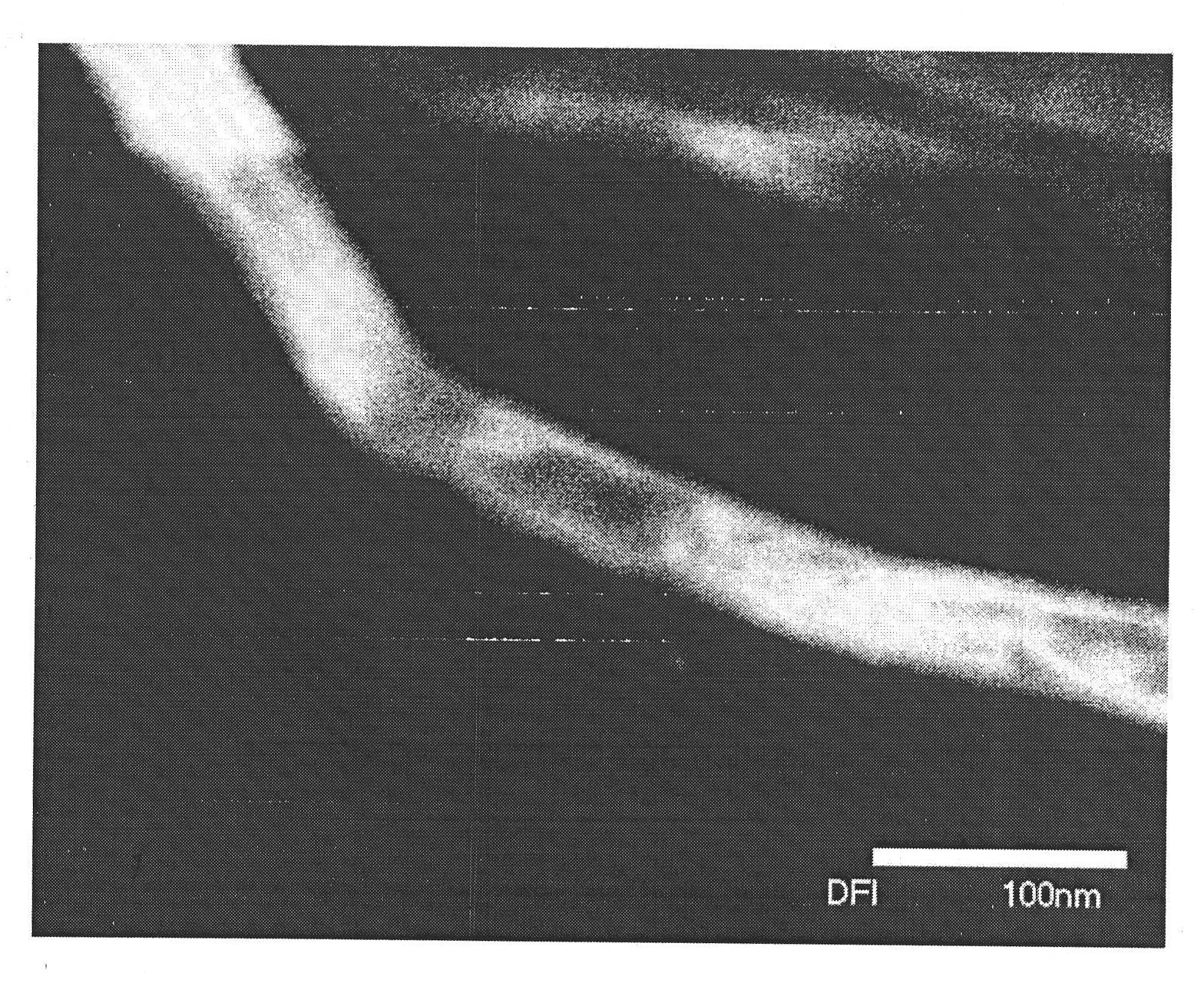

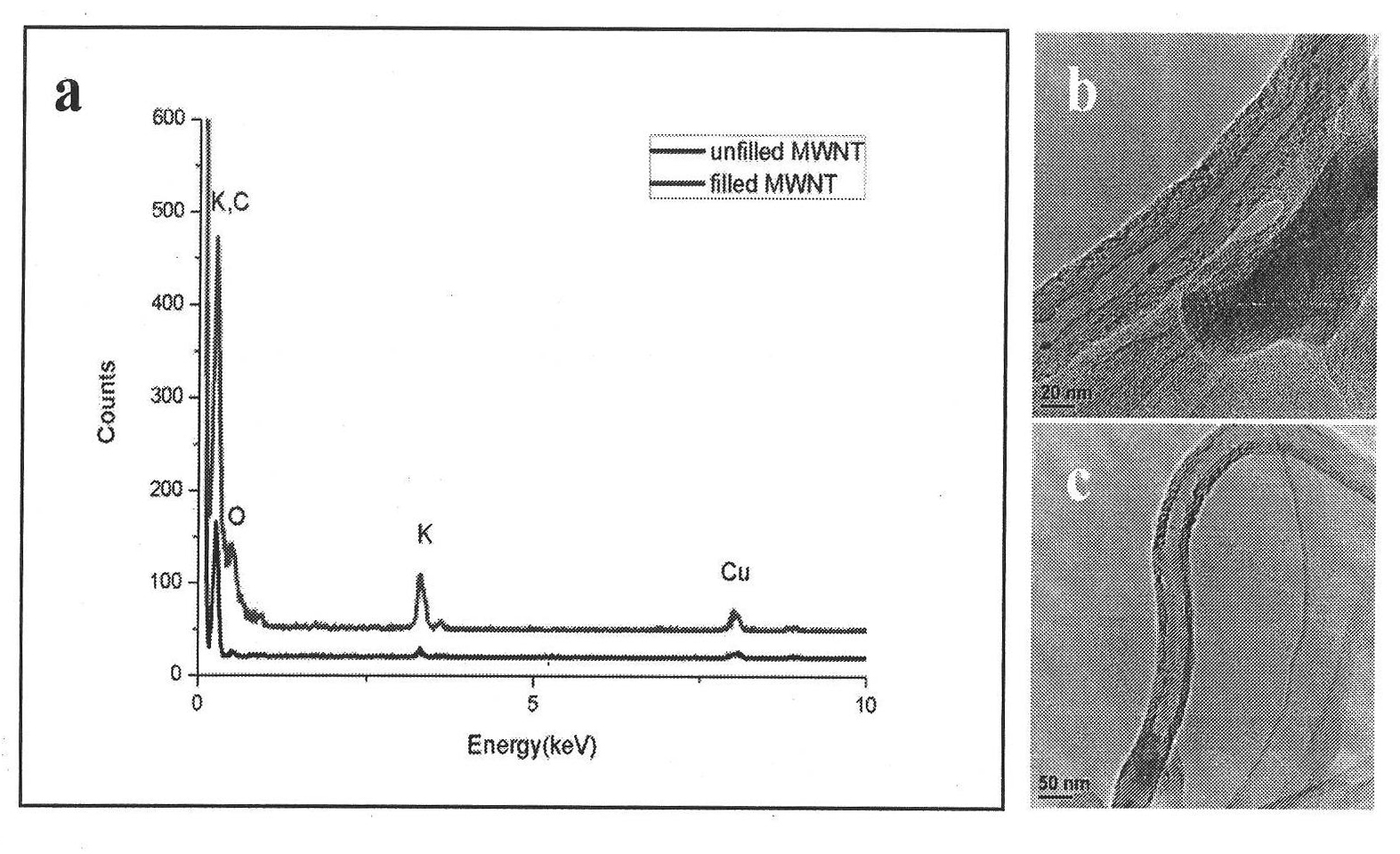

Image

Examples

Embodiment 1

[0023] 1. Place the multi-walled carbon nanotubes in air for calcination at 300°C for 1 hour, then place them in a tube furnace with argon-hydrogen mixture and heat at 800°C for 1 hour;

[0024] 2. Add carbon nanotubes to 12mol / L concentrated hydrochloric acid and reflux at 200 degrees for 4 hours, then filter and clean the carbon tubes until neutral, and dry at 70 degrees;

[0025] 3. In an argon-protected glove box, weigh the elemental potassium and carbon nanotubes according to the mass ratio of 3:1 (30mg potassium with 10mg carbon nanotubes) and put them into a glass tube to vacuumize and seal;

[0026] 4. Put the sealed glass tube into the muffle furnace and heat it at 100 degrees for 8 hours, and take it out after cooling;

[0027] 5. After breaking the glass tube, quickly put it into a beaker filled with 500mL water;

[0028] 6. Filter and wash the reacted product, and dry it at 80°C.

Embodiment 2

[0030] 1. Place the single-walled carbon nanotubes in the air for calcination at 400 degrees for 1 hour, and then place them in a tube furnace with argon-hydrogen mixture and heat them at 900 degrees for 1 hour;

[0031] 2. Add carbon nanotubes to 12mol / L concentrated hydrochloric acid and reflux at 100°C for 4 hours, then filter and clean the carbon nanotubes until neutral, and dry at 80°C;

[0032] 3. In an argon-protected glove box, weigh the elemental potassium and carbon nanotubes according to the mass ratio of 2:1 (20mg potassium with 10mg carbon nanotubes) and put them into a glass tube to vacuumize and seal;

[0033] 4. Put the sealed glass tube into the muffle furnace and heat it at 200 degrees for 8 hours, and take it out after cooling;

[0034] 5. After breaking the glass tube, quickly put it into a beaker filled with 500mL ethanol;

[0035] 6. Filter and wash the reacted product, and dry it at 80°C.

Embodiment 3

[0037] 1. Place the double-walled carbon nanotubes in the air for calcination at 500 degrees for 1 hour, and then place them in a tube furnace with argon-hydrogen mixture and heat them at 1000 degrees for 1 hour;

[0038] 2. Add carbon nanotubes to 12mol / L concentrated hydrochloric acid and reflux at 300 degrees for 5 hours, then filter and clean the carbon tubes until neutral, and dry at 100 degrees;

[0039] 3. In the argon-protected glove box, weigh the elemental lithium and carbon nanotubes according to the mass ratio of 1:1 (10mg lithium with 10mg carbon nanotubes) and put them into a glass tube to vacuumize and seal;

[0040] 4. Put the sealed glass tube into the muffle furnace and heat it at 300 degrees for 9 hours, and take it out after cooling;

[0041] 5. After breaking the glass tube, quickly put it into a beaker filled with 500mL12mol / L concentrated hydrochloric acid;

[0042] 6. Filter and wash the reacted product, and dry it at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com