Method for manufacturing micro-polarizer array based on metal nanometer grating

A technology of micro polarizer array and manufacturing method, which is applied in the direction of polarizing element, photographic plate-making process of pattern surface, optics, etc., can solve the problems of poor shape of polarizer array, poor polarization performance, complicated process, etc., and achieve high extinction Ratio, good straight wall, high resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

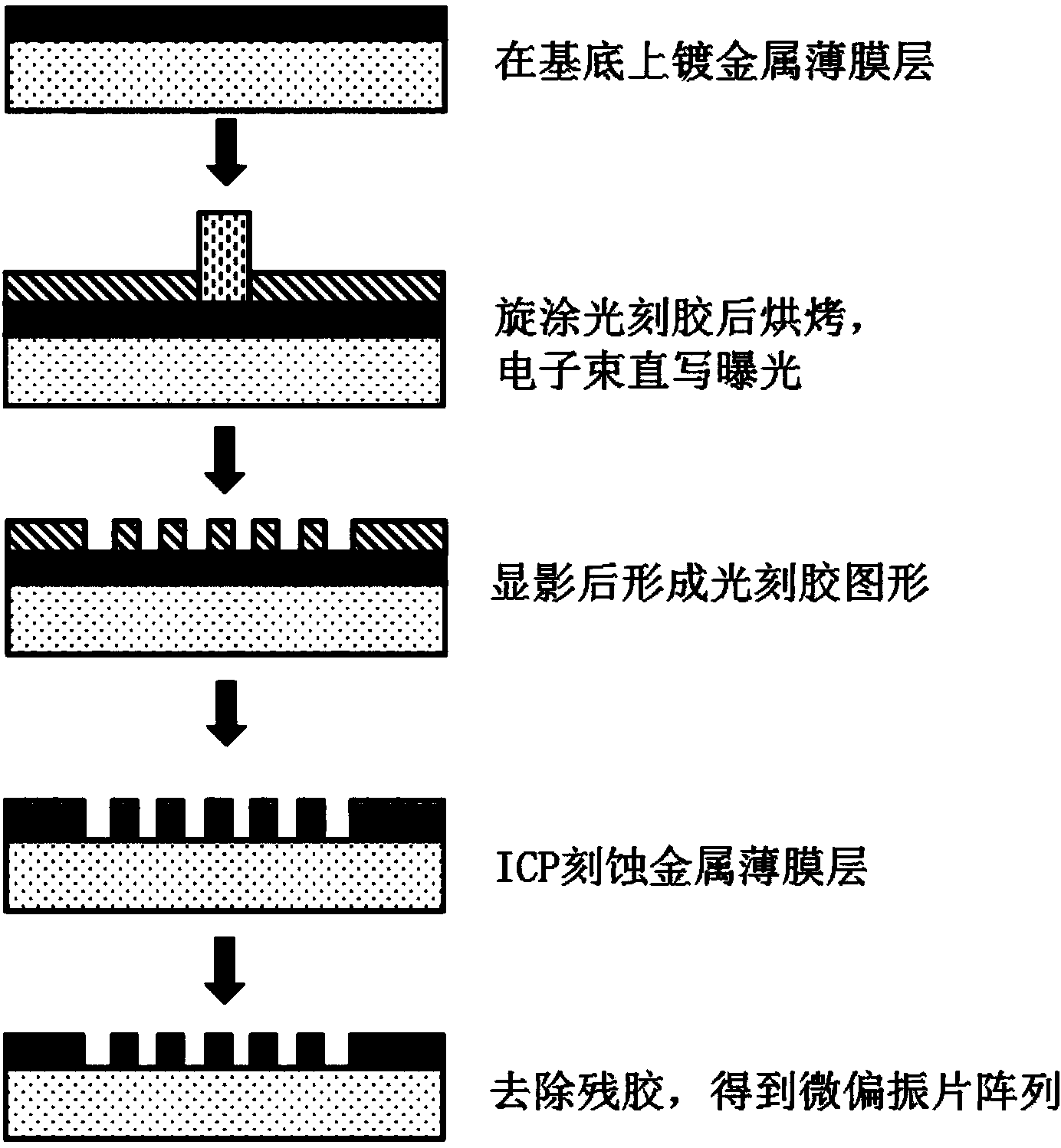

[0034] according to figure 2 As shown in the process flow, the method for preparing a micro-polarizer array based on a metal nano-grating by using a single electron beam exposure provided in this embodiment includes the following steps:

[0035] Step 1: Deposit a thin film layer of metallic aluminum (Al) on a glass substrate.

[0036] In this step, a 100nm-thick metal Al thin film layer is deposited on the cleaned glass substrate by using magnetron sputtering technology. According to the extinction requirement, the thickness of the Al thin film layer can be any value between 100-150 nm.

[0037] Step 2: Spin-coat the electron beam photoresist on the glass substrate with the metal Al film layer, and form the electron beam photoresist pattern of the micropolarizer array after exposure and development. The specific process is as follows:

[0038]a. Place the glass substrate with metal Al thin film layer on a hot plate and bake at 180°C for 5-10 minutes to remove the moisture o...

Embodiment 2

[0047] according to figure 2 As shown in the process flow, the method for preparing a micro-polarizer array based on a metal nano-grating by using a single electron beam exposure provided in this embodiment includes the following steps:

[0048] Step 1: Deposit a metal chromium (Cr) film layer on a glass substrate.

[0049] In this step, electron beam evaporation technology is used to deposit a 120 nm thick metal Cr thin film layer on the cleaned glass substrate. According to the extinction requirement, the thickness of the Cr thin film layer can be any value between 100-150 nm.

[0050] Step 2: Spin-coat the electron beam photoresist on the glass substrate with the metal Cr film layer, and form the electron beam photoresist pattern of the micropolarizer array after exposure and development. The specific process is as follows:

[0051] a. Place the glass substrate with the metal Cr film layer on a hot plate and bake at 150°C for 5-10 minutes to remove the moisture on the su...

Embodiment 3

[0060] according to figure 2 As shown in the process flow, the method for preparing a micro-polarizer array based on a metal nano-grating by using a single electron beam exposure provided in this embodiment includes the following steps:

[0061] Step 1: Deposit a metal (Al) thin film layer on a glass substrate.

[0062] In this step, an electron beam evaporation technique is used to deposit a 100 nm-thick metal Al thin film layer on the cleaned glass substrate. According to the extinction requirement, the thickness of the Al thin film layer can be any value between 100-150 nm.

[0063] Step 2: Spin-coat the electron beam photoresist on the glass substrate with the metal Al film layer, and form the electron beam photoresist pattern of the micropolarizer array after exposure and development. The specific process is as follows:

[0064] a. Place the glass substrate with metal Al film layer in an oven and bake at 170°C for 40 minutes to remove the moisture on the surface, spin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com