Micro nano structure direct-writing device

A technology of micro-nano structure and writing device, which is applied in the direction of nano-structure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as difficulty, reduce line width, limit application range, etc., achieve spinning voltage reduction, increase utilization rate, reduce The effect of development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

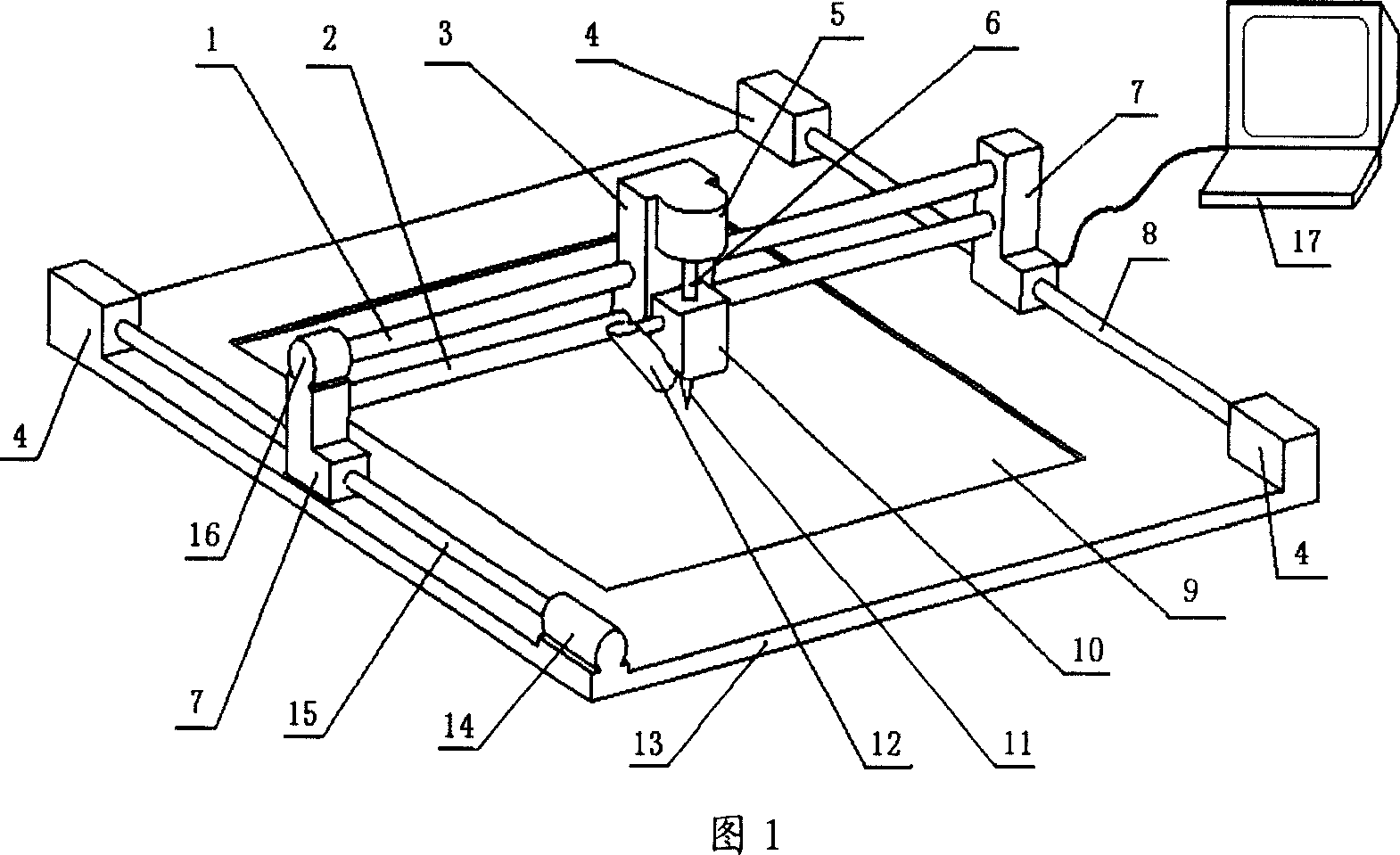

[0018] Referring to Fig. 1, the microprobe control platform of the present invention is provided with Y-direction linear guide rail 1, Y-direction limit slide bar 2, Y-direction slider 3, fixed support 4, Z-direction linear guide rail controller 5, Z-direction linear guide Guide rail 6, X-direction slider 7, X-direction limit slider 8, direct writing area 9, precision flow control and high-voltage electrostatic power supply 10, probe 11, CCD microscope 12, high-speed precision X-Y platform 13, X-direction linear guide rail control Device 14, X-direction linear guide rail 15, Y-direction linear guide rail controller 16 and control computer 17.

[0019] Among them, the X-direction linear guide rail 15 and the Y-direction linear guide rail 1 are driven by the X-direction linear guide rail controller 14 and the Y-direction linear guide rail controller 16 respectively, and control the probe 11 according to the positioning information given by the control computer 17. Precise positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com