Gas compressor stator blade grid with equal-depth grooves formed in end walls

A compressor and cotyledon cascade technology, which is applied in the field of compressor static cotyledon cascades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

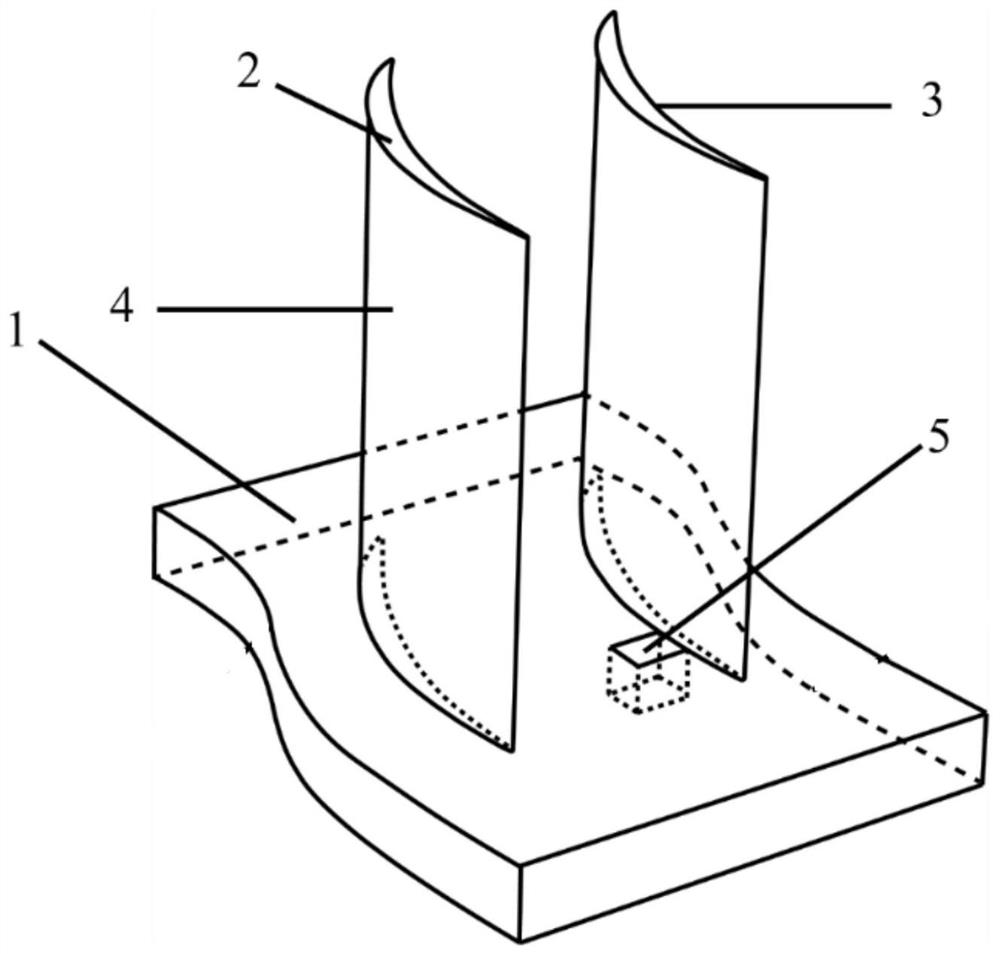

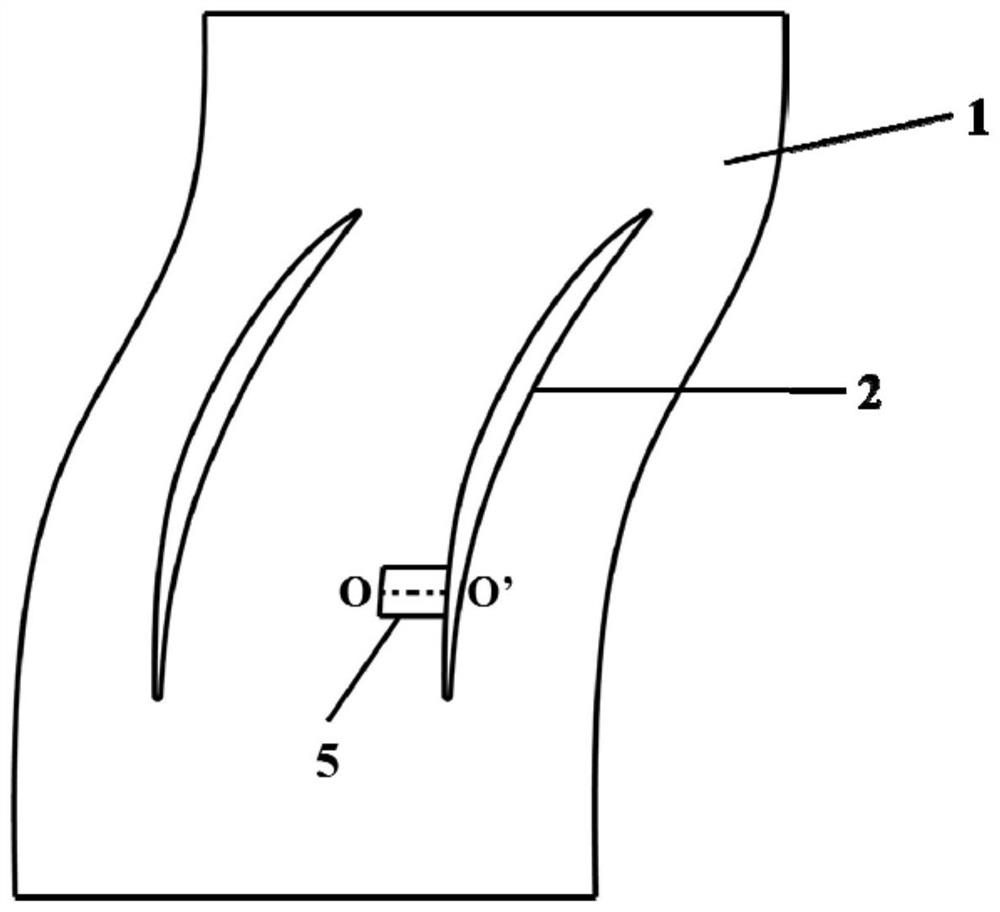

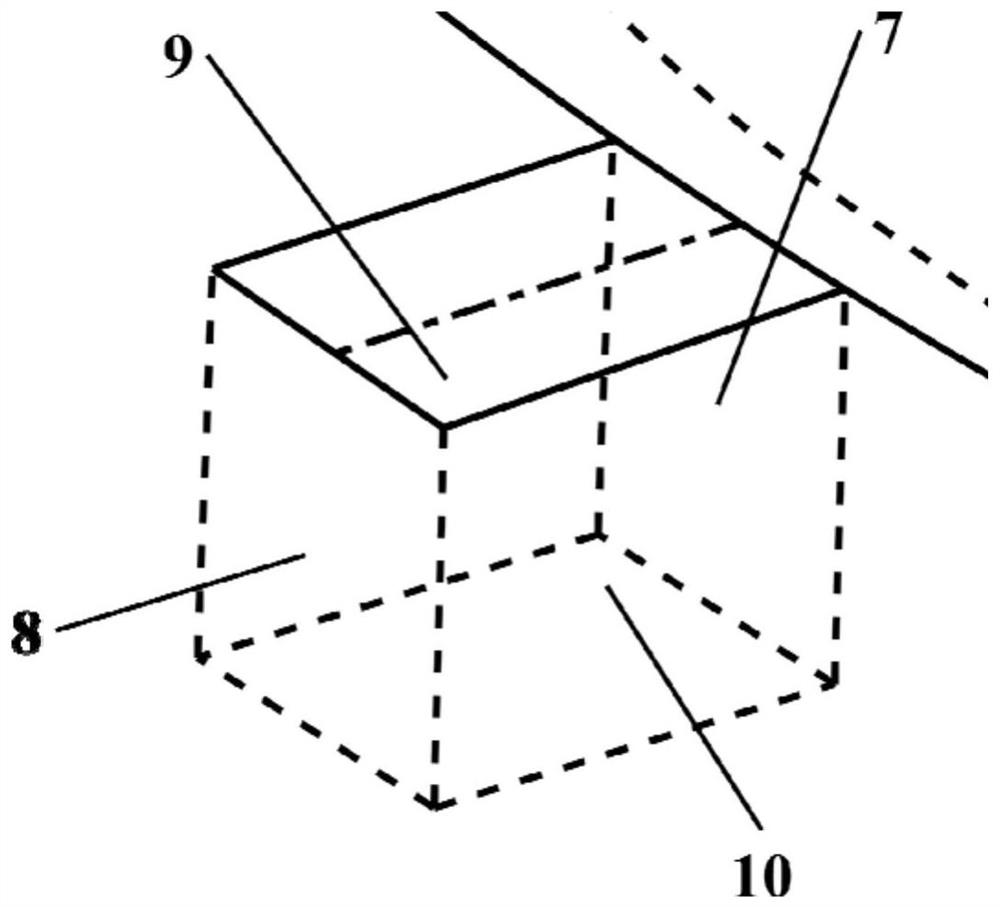

[0021] Such as Figure 1-Figure 3 As shown, the compressor stator cascade with equal-depth grooves on the end wall provided by the present invention includes a lower end wall 1, an upper end wall, and a plurality of blades 2 arranged side by side between the lower end wall 1 and the upper end wall; wherein, two adjacent The space between the blades 2 is the cascade passage, the blades 2 are arc-shaped plates, the inner arc surface is the pressure surface 3, the outer arc surface is the suction surface 4, and the inner arc surface and the outer arc surface have two intersections in the axial direction. line, where the intersection line close to the intake direction is the leading edge line, the intersection line close to the exit direction is the trailing edge line, the distance between the leading edge line and the trailing edge line is the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com