Marine Subsea Assemblies

a technology of subsea risers and assemblies, applied in the field of assemblies, can solve the problems of not being suitable for use with other wells, subsea risers (free-standing or not) being known as suitable for such use, and prior containment efforts did not address the fluid properties produced. , to achieve the effect of small flow rate of functional fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0126]In the following description, numerous details are set forth to provide an understanding of the disclosed methods, systems, and apparatus. However, it will be understood by those skilled in the art that the methods, systems, and apparatus may be practiced without these details and that numerous variations or modifications from the described embodiments may be possible. All U.S. published patent applications and U.S. patents referenced herein, as well as any non-published U.S. patent applications and published non-patent literature are hereby explicitly incorporated herein by reference. In the event definitions of terms in the referenced patents and applications conflict with how those terms are defined in the present application, the definitions for those terms that are provided in the present application shall be deemed controlling.

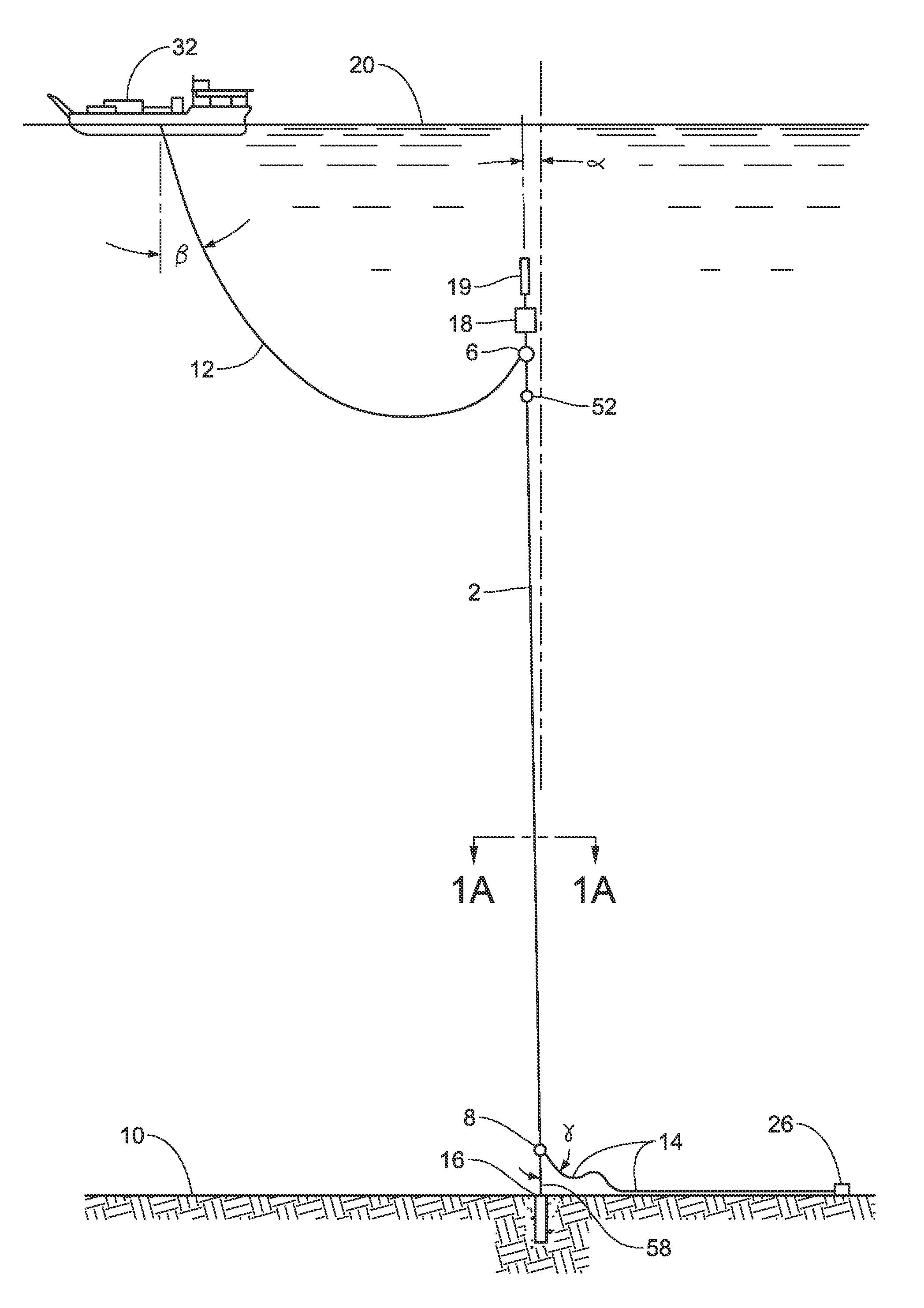

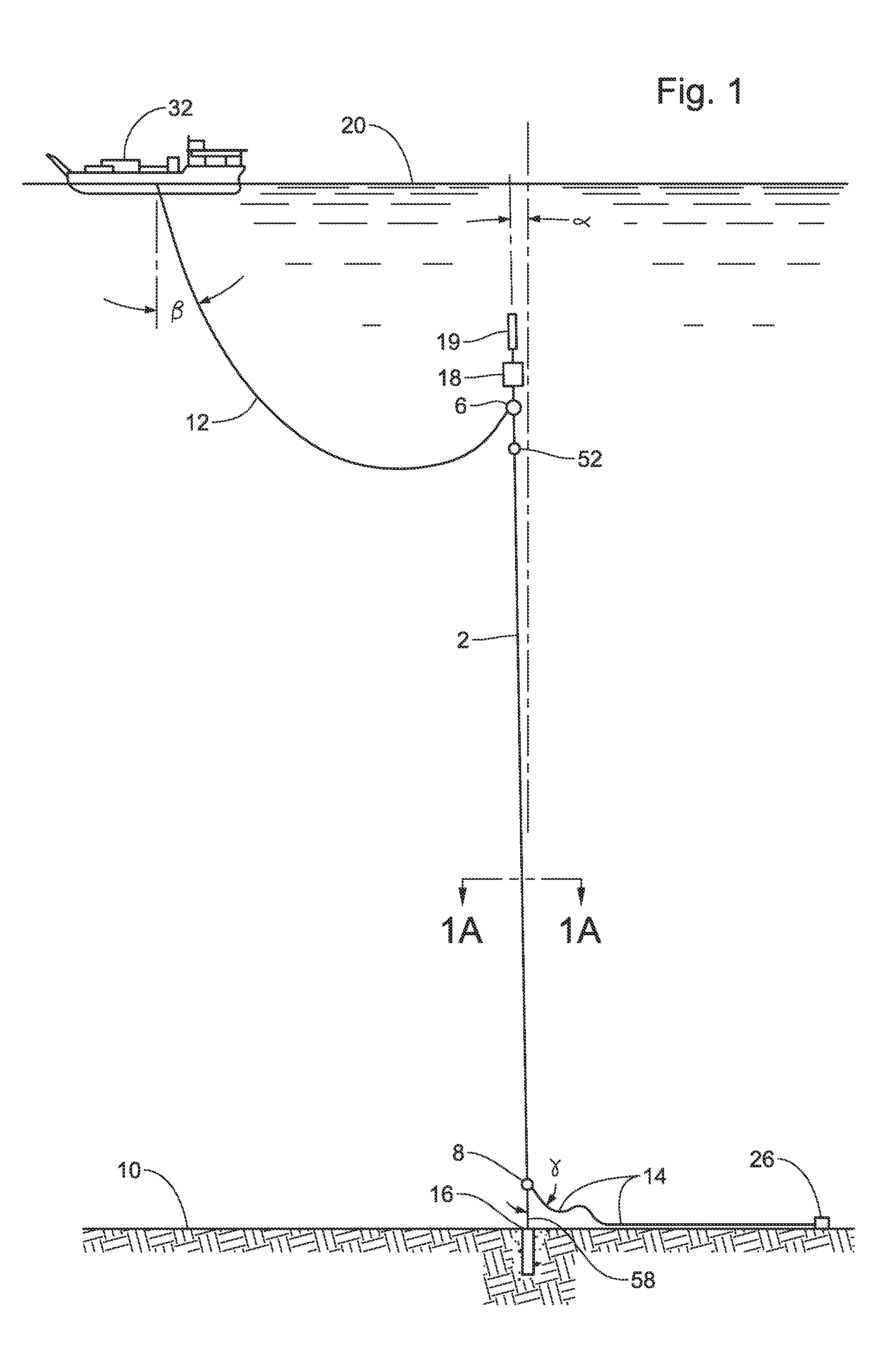

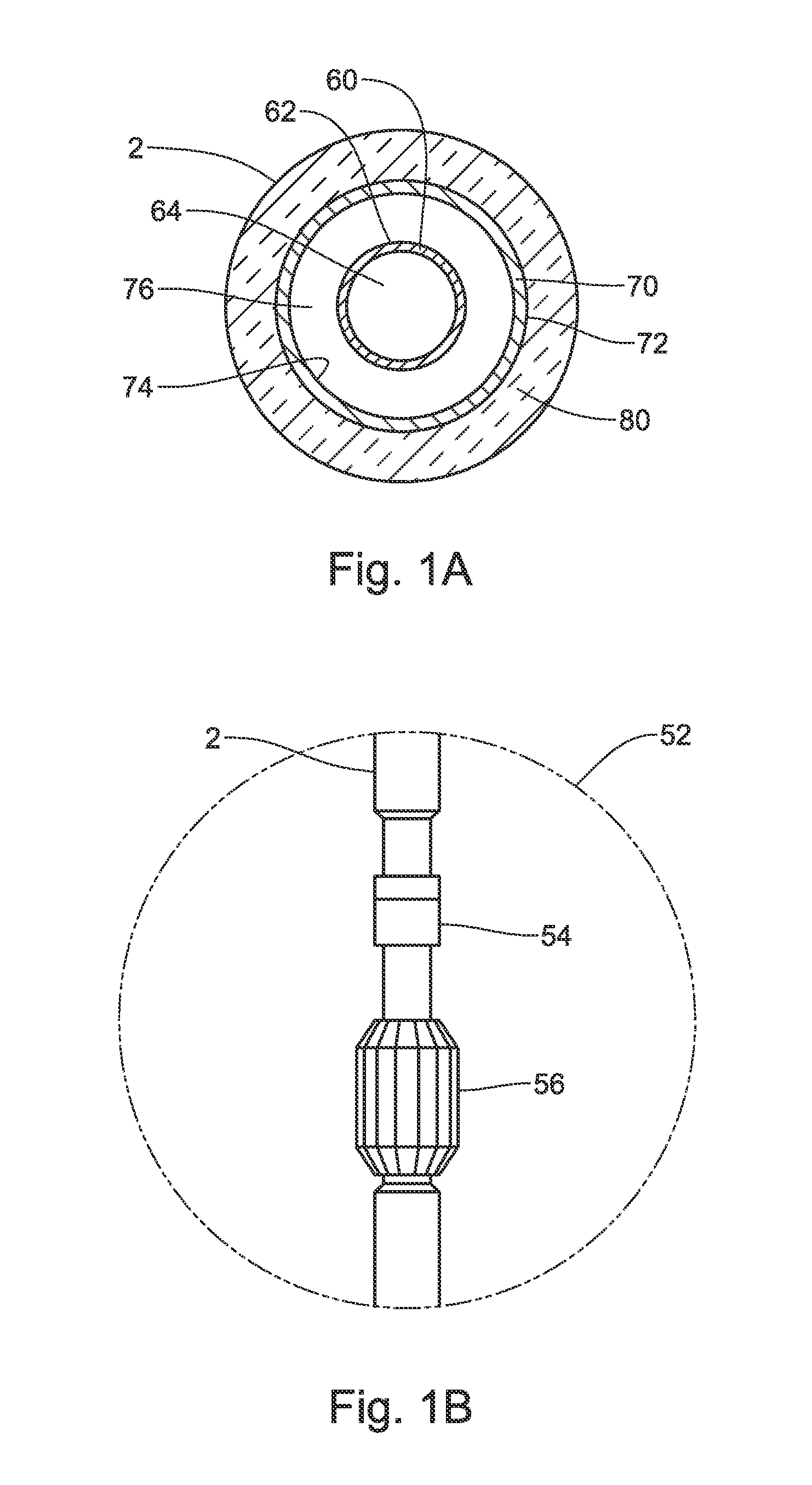

[0127]The primary features of various embodiments of the present disclosure will now be described with reference to the drawing figures. The same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com