Pump device

a pump body and fluid technology, applied in the direction of positive displacement liquid engines, pump bodies, machines/engines, etc., can solve the problems of difficult operation of only one pump body, difficult downsizing, etc., and achieve the effect of easy miniaturization and small flow ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Several embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

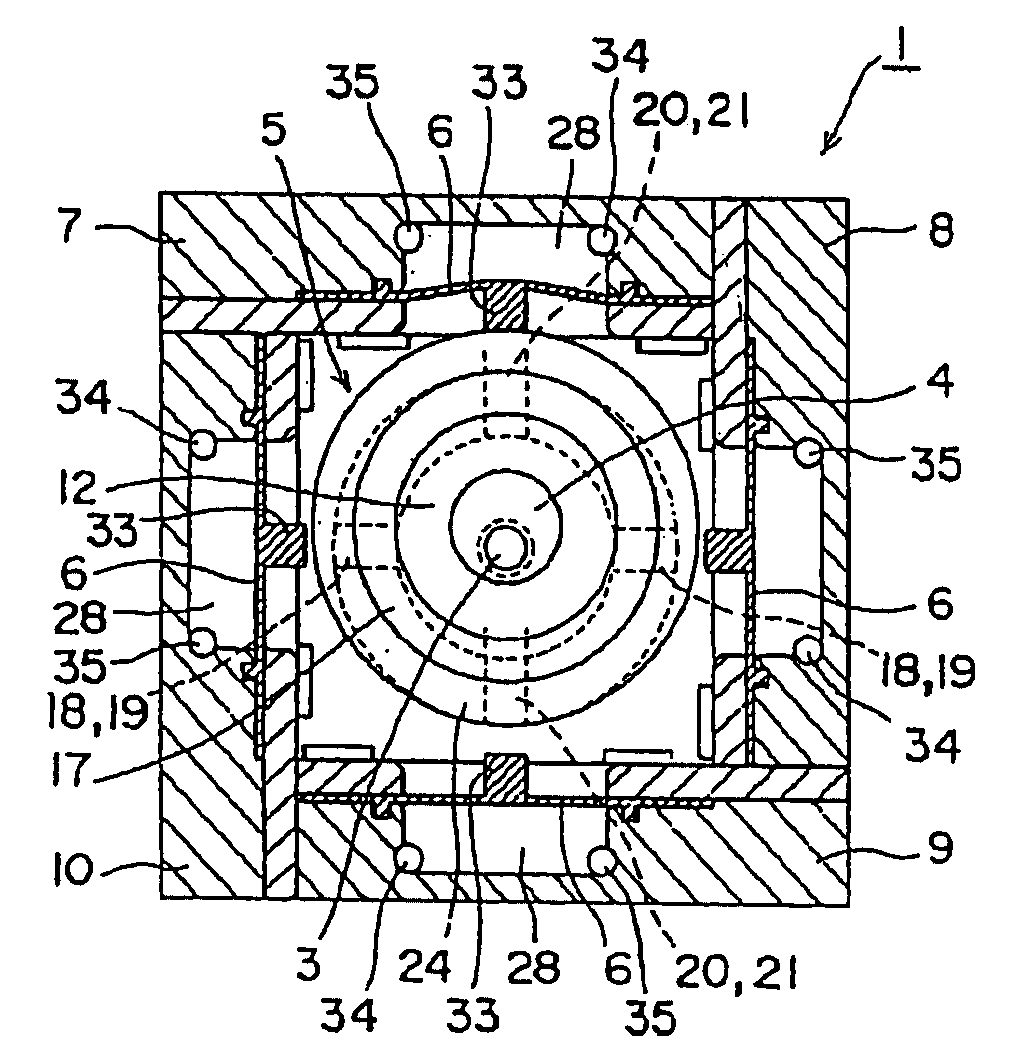

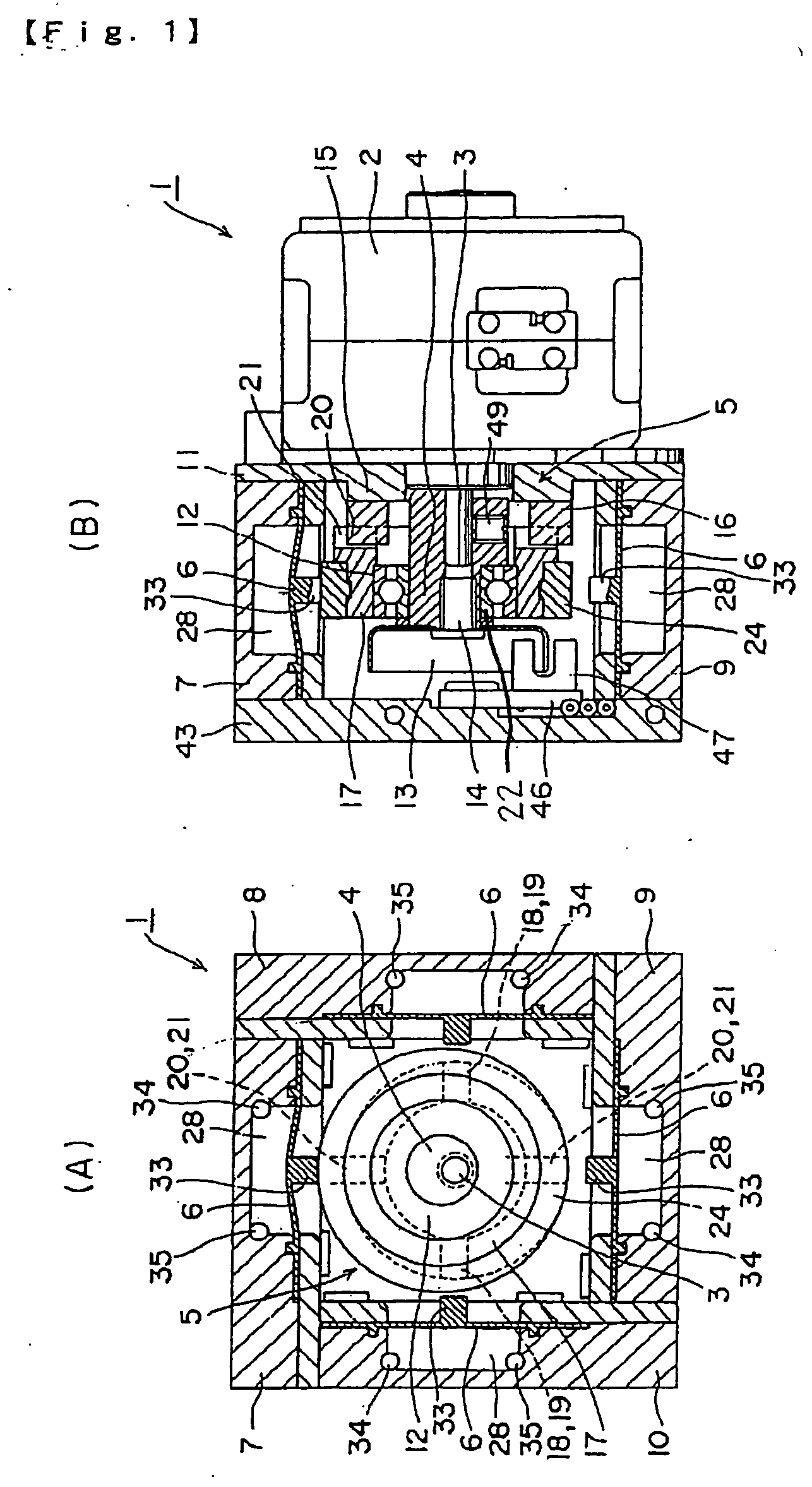

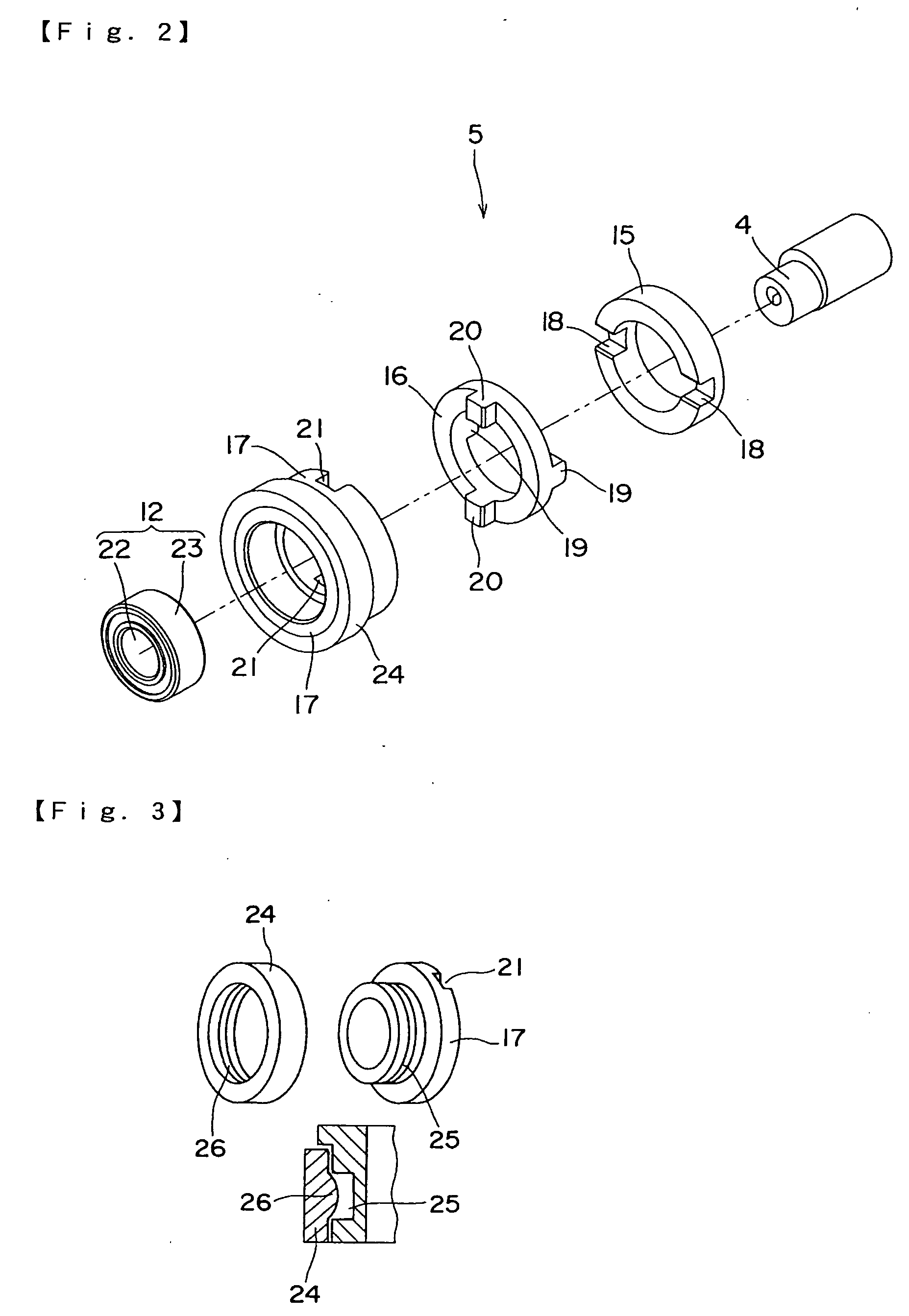

[0048] A pump device 1 in accordance with an embodiment of the present invention is shown in FIGS. 1 through 15. The pump device 1 includes a motor 2, an eccentric member 4 eccentrically mounted on the output shaft 3 of the motor 2, a cam mechanism 5 which engages with the eccentric member 4 for converting the turning or rotating motion of the eccentric member 4 into a motion in a radial direction of the output shaft 3, and pump bodies 7 through 10 each of which is provided with a diaphragm 6 for performing a pump operation that is moved in the radial direction of the output shaft 3 by the operation of the cam mechanism 5 as shown in FIGS. 1(A) and 1(B).

[0049] The motor 2 is a stepping motor. The motor 2 is mounted on a support plate 11 with a screw. The inner ring 22 of a ball bearing 12 is mounted on the eccentric member 4, for example, by press fitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com